LATEST UPDATE الاشتراك

How to Start Plastic Recycling Business? A Complete Guide to Choosing the Right Recycling Machine

Plastic recycling is a growing industry. There are numerous factors to consider if you want to start a recycling business. You must decide what types of plastics you will recycle, determine the location of your business, research local and state requirements, research your customers, set up accounts with plastic buyers, and, most importantly, invest in a reliable plastic recycling machine.

Sustainability Benefits for Plastic Film Producers

Why do producers want to recycle plastics? Although plastic is a very popular material, on a global level, less than 10% of it is recycled. With plastic waste being in such a high supply, producers could benefit from incorporating recycling into their existing business model. A recent study by business and daily found that 72% of the respondents are actively buying more environmentally friendly products than they did 5 years ago.

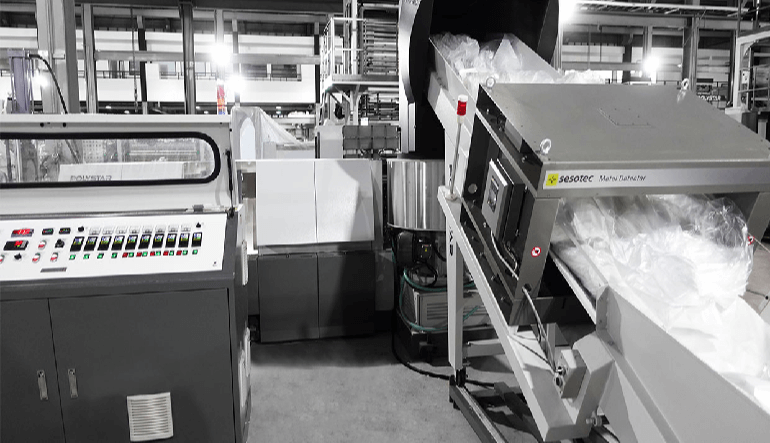

5 Tips to Increase Efficiency in Plastic Recycling Process

In parallel with the increase in the consumption of plastics, driven by economic development and population growth, global plastic waste is projected to triple by 2060 based on OECD reports. Increasing plastic recycling efficiency is one of the major keys to returning more plastic waste to production lines as a valuable recycled polymer. Here we have listed 5 tips to increase efficiency in the plastic recycling process.

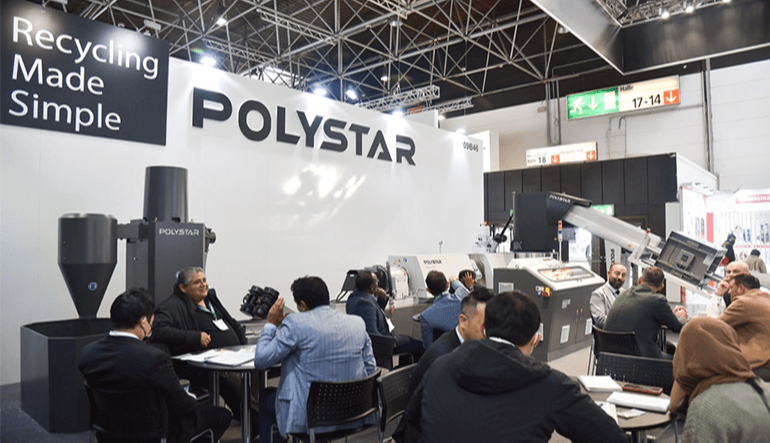

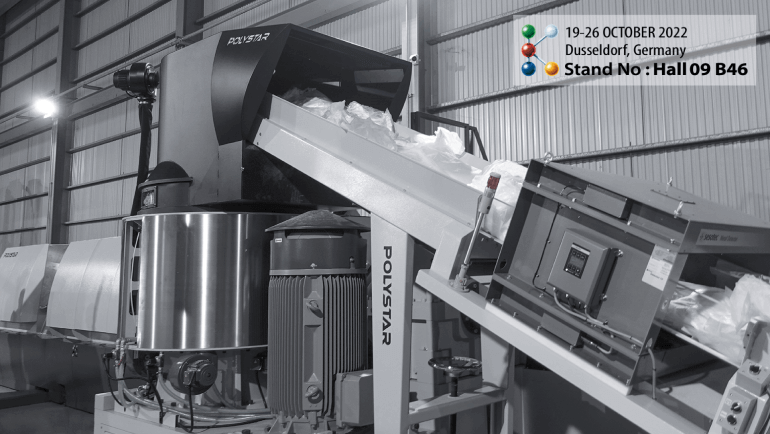

K Show 2022 -Recycling for Post-consumer and Post-industrial Plastics on the Rise

New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste.

Recycling for Post-consumer and Post-industrial Plastics on the Rise

It may be good for everyone to be in the plastic recycling business whether you are a recycler or a producer. New regulations in many countries now require producers to use a higher percentage of recycled content in flexible and rigid packaging products. The instability of raw material prices and supplies also forces plastic producers to better recycle their production waste. With the great importance of recycled-based plastic products, the global demand for plastic recycling is expanding.

Crucial Factors for a Complete Circular Economy

The production of plastic bags and plastic films around the globe is huge. In recent years, producers have implemented new technologies to complete a circular economy in their factories. To make this possible, producers need a plastic recycling system that produces good quality pellets and a blown film machine that can process up to 100% recycled plastic pellets.

Start Your CPP Film Recycling Right Away with POLYSTAR

Cast polypropylene, also known as CPP, is well known for its versatility. CPP is gaining popularity as a more appealing packaging material than polyethylene in many areas because it has higher clarity and better heat resistance. The qualities of the CPP film can be customized to fit specific packaging, performance, and processing needs...

POLYSTAR: How to Use Recycled Pellets in the Production Process - Post-consumer Waste

Plastic pellets are small granulates, used in Blown Film Machines, Injection Machines, Molding Machines, and other machines that produce plastic films, bottles, containers, bags, and more. These small pieces of material are the most important...

POLYSTAR: What is the Difference between Post-industrial Recycling and Post-consumer Recycling?

When it comes to plastic recycling, there are a few things you should know before deciding on the right machines. There are two types of plastic recycling in general, Post-industrial recycling and Post-consumer recycling. In this article, I will explain the difference between recycling these two types of plastic waste.

POLYSTAR: Recycled Plastic Pellets from PP Raffia and Woven Production – Tips to Reuse them Better

Which recycled plastic pellets should go back to PP tape extrusion line? On average, a 5-10% production waste is generated during the PP woven bag making process at different stages of the production: extruder start-up lumps, waste due to blockage in extruder die head, tape winding, circular loom (weaving defects), coating/lamination stage, pp woven/FIBC bag conversion and printing.

Recycling- Bigger Pelletizing Extruders in High Demand

With the growing importance of recycled-based products for both rigid and flexible packaging, the demand for plastic recycling continues to increase worldwide. Recyclers are now buying multiple machines at the same time and more notably, larger-capacity machines.

POLYSTAR: Does your Factory have the Right Solution for Recycling your Materials?

Producers understand the relevance of recycling the plastic waste created by their facilities. The shortage of resins drove plastic producers to respond faster and take action to recycle their factory waste, and thus to explore innovative ways to recycle post-consumer waste.