LATEST UPDATE الاشتراك

Looking for a High-Value Recycling Machine for 2025? Discover How the Repro-Flex Meets All Your Needs!

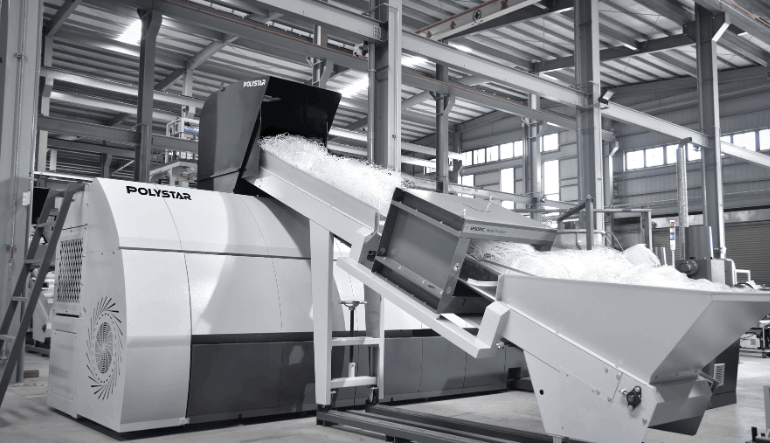

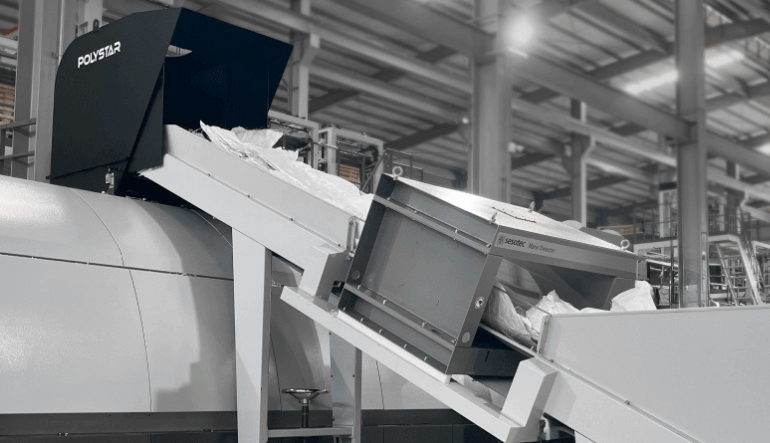

POLYSTAR’s Repro-Flex recycling machine produces high-quality, hole-free pellets. Unlike other systems, POLYSTAR’s technology delivers smooth, uniform pellets that enhance the strength and appearance of plastic films. These pellets ensure scratch-free, durable, and visually appealing products.

Shaping the Future of Plastic Recycling in the USA with POLYSTAR

The United States is putting more emphasis on sustainable practices. One area getting a lot of attention is plastic recycling, which is evolving rapidly in response to growing environmental awareness and shifting consumer habits. This industry is all about giving plastic waste a new life, from turning everyday items like used bottles, containers, and packaging into raw materials for new products to reducing the plastic piling up in landfills.

POLYSTAR PP Raffia Recycling: An Eco-Friendly and Cost-Effective Approach for Manufacturers

PP raffia is a strong, durable, and cost-effective plastic widely used across various industries. However, improper disposal can lead to environmental harm. Fortunately, PP raffia is recyclable, offering manufacturers a sustainable solution to minimize their environmental impact while also benefiting economically.

How to Choose the Right POLYSTAR Recycling Machine Based on Your Plastic Waste?

Follow the guidelines to choose the right POLYSTAR plastic recycling machine that processes your plastic waste efficiently and with a high yield.

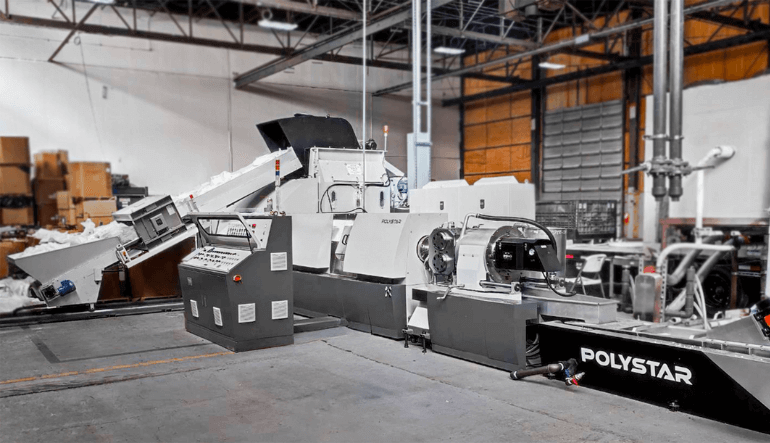

BDB Recycling Leads the Way with POLYSTAR's Innovative Solutions

POLYSTAR is dedicated to creating innovative pelletizing machines that empower businesses to contribute to a more sustainable future. We'd like to highlight one of our valued customers, BDB Recycling, located in Ohio. BDB Recycling shows how our pelletizing machines can revolutionize LDPE/HDPE recycling operations, not only boosting their business but also paving the way for a more circular plastics economy across the US.