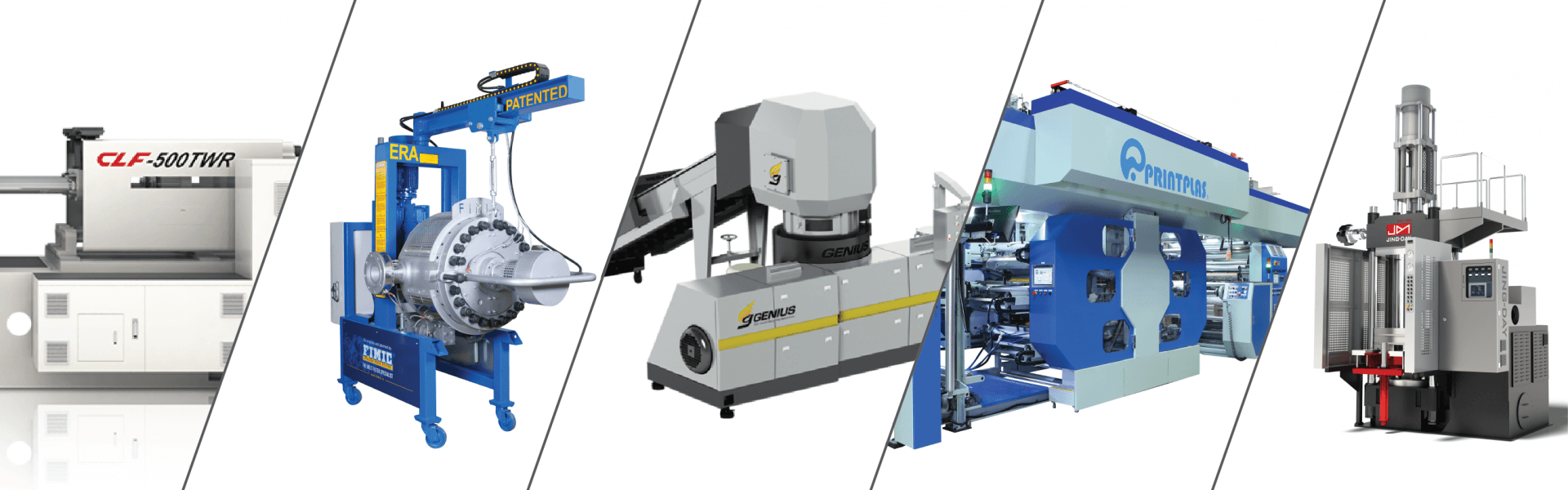

Plastics & Rubber Machinery Videos

With PRM professional matching services, we labeled 15 Machinery Categories and more than 600 videos, for you to conveniently find a supplier that best suits your business.

ALL STYLES

AUXILIARY EQUIPMENT AND INTEGRATED AUTOMATION

BLOW MOLDING MACHINES

EXTRUDERS AND EXTRUSION LINES

FINISHED/SEMI-FINISHED PRODUCTS

INJECTION MOLDING MACHINES

MOLDS AND DIES

PACKAGING MACHINERY

PARTS AND COMPONENTS

PLASTIC CONVERTING MACHINES

PLASTIC RECYCLING & MATERIAL PROCESSING MACHINERY

PRINTING MACHINERY

RAW MATERIALS & ADDITIVES

RUBBER PROCESSING MACHINERY

SHOE MAKING MACHINERY

THERMOFORMING MACHINES

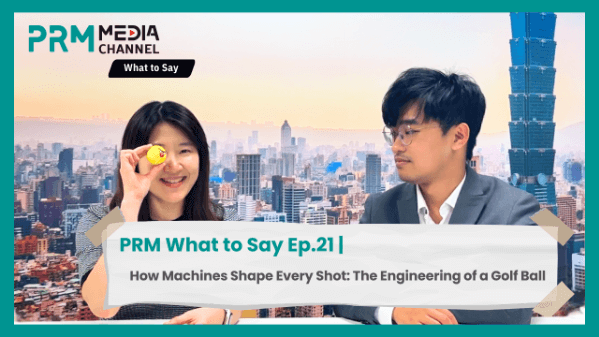

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

High Speed Side Sealing Machine with Wicketer

Jia Thai Industrial Co., Ltd. Company Profile

Hydraulic Slitter and Cutting Machine

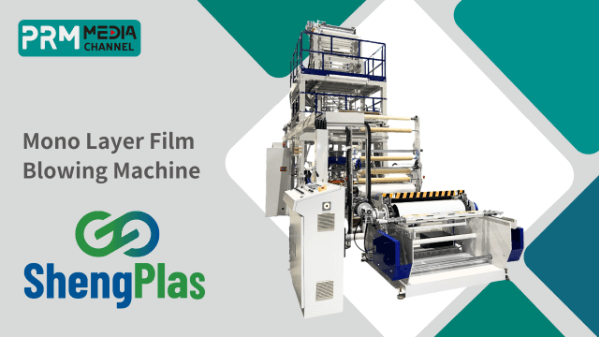

Mono Layer Film Blowing Machine

Yicheen High Precision Die Cutting Machine offers a variety of options, such as CCD Auto Positioning, Auto movable Stacking, etc., click the link to see more Die Cutting Machine info: ???? https://bit.ly/3qbjbtf

*Accurate bag length control by Servo Motor

*Gripper bag transfer system, most advanced design

*Maximum output 50 bag/min *Optional devise such as Gusset, Powder Brake, Easy Open function, Punch system, Liner Insert, Bottom Wrap

*Union Special Sewing machine customized model available

For more information, visit http://www.botheven.com.tw

Expanded TPU Low density High elasticity ISOTHANE TPU Foam bead has light density and high elasticity even at -25°C. It even withstands prolonged and repeated compression without permanent deformation. TPU Foam bead (expanded thermoplastic polyurethane) offers a perfect combination of soft texture and great elasticity. ISOTHANE TPU Foam bead - colorful foam beads with high elasticity, customized different color and particle size for lightening era. ISOTHANE TPU Faom bead Suitable for footwear materials, Buffer device for sports, Bicycle saddles , Running tracks, Airless tires. → For more information please check GRECO official website: https://reurl.cc/OVDRy

EPS Foam Sheet Machine can be widely used in packaging materials, such as food trays, eps food Packaging.

Learn more https://www.extrusion.com.tw/en/products.html

Contact Us https://www.extrusion.com.tw/en/contact.html

/ EPS Foam Sheet Machine Features /

Machines provide customized services.

Application: Food Tray / Packaging Material.

Output: From 200 kg/hr. to 720 kg/hr. for EPS.

Configure a color screen to instantly view productivity.

Safe and high quality.

/ About Chi Chang - Plastic Extrusion Machine Manufacturer /

Chi Chang have been committed to the design and fabrication of extrusion equipment for over 45 years. Our user-friendly and performance-oriented innovative technology reduces the operating workload of workers, reduces the operating costs, increases the overall production capacity and this in turn generates more profit. You can rely on Chi Chang to simultaneously secure both profit and quality for our clients.