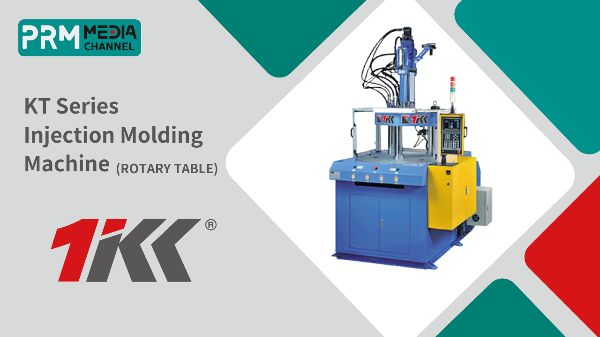

KT Series Injection Molding Machine (ROTARY TABLE) | TAIWAN KINKI

KT Series Injection Molding Machine Vertical mold clamping and injection, small footprint and high degree of precision. This machine is ideal for injection of medium and small products with inclusions. Dual-cylinder injection system offers high injecting pressure for fast operation, making this injection machine your best choice for production of thin items. Direct-pressure mold clamp allows even injection force, and the relatively low pressure means maximum precision and an incredibly smooth cycle of operation. Choose a platen or a rotary plate in accordance with the type of products to be injected, in order to achieve the best possible in feed and injection effects. This machine offers a wide range of programmable functions including automatic inclusion, extraction and fully-automatic production. There are also many other control systems that facilitate flexible production and keep costs low while maximizing precision.

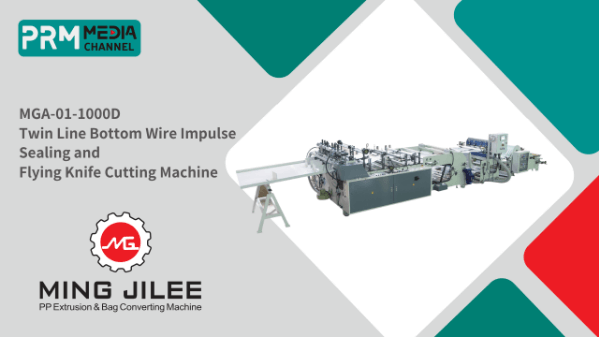

Twin Line Bottom Wire Impulse Sealing and Flying Knife Cutting Machine MGA-01-1000D | MING JILEE

Twin lines Bottom Bag impulse sealing and flying knife cutting machine, MGA-01-1000D

Ultrasonic Metal Welding Machine-ULTRA6200-M-WT | MING JILEE

ULTRA6200-M-WT Ultrasonic Metal Welding Machine

2024 NPE Orlando Interview | ISI

I had the pleasure of meeting Mr. Joe Whann at NPE Orlando. Joe is not only brilliant but also incredibly friendly! He provided an insightful introduction to the wide range of services offered by ISI and shared how they have become a leading agent in the USA. Don't miss out on learning about their impressive journey and expertise!

All Electric Molding Machine | CLF

All Electric Injection Molding Machine Features: ⚫Electricity Regeneration Circuit Electricity Saved by 15% ⚫Employs German Siemens control and servo motors for excellent performance and high accuracy. ⚫High performance injection unit that enhances the exceptional features of servo control.High speed,stability and accuracy are guaranteed. ⚫In-house software development capability combined with technical support from Siemens. ⚫Standardized hardware design simplifies the maintenance works and reduces the spare parts stock. ⚫Simultaneous control on multi-axes shortens molding cycle time dramatically. ⚫Overall super rigid structure minimizes running vibration. ⚫Exclusive energy-regeneration function not only provides electricity-saving and environmental protection, but also meets today's trend of energy-saving. ⚫Ergonomics operation interface. ⚫The access level to controller management can be ranked. ⚫Rigid platen design exhibits superior parallelism. ⚫Supports remote monitoring functions.

2023 Plastics & Rubber Indonesia On-site Tour | PRM-TAIWAN

Check our on-site tour video for Plastics & Rubber Indonesia 2023! Taiwanese suppliers, which is specialized in the Plastic & Rubber industry, known as its high quality machinery. If you don't want to miss out the latest news, stay tuned!

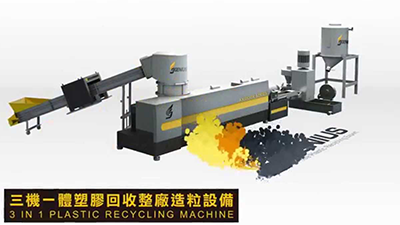

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS Specializes in waste plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in waste plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our waste plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature: -Drive-train: High torque gearbox made with precision grinding. Low noise, steady and smooth operation. -Low power consumption, high output. Dedicated screw and barrel design: According to the characteristics of recycle materials, dedicated screw is designed to completely impurities such as water and bad air; the screw also has a variety of advantages, for examples, good mixing, good dispersion, high output, and others. Die head pelletizing eliminates the labor cost on batter brace. No water tank. Consumes less space. Extruder is equipped with pressure sensors. When there is excessive pressure, warning light or buzzer send notification for replacing filter screen. No need to shut down the machine when replacing the filter screen. Single extruder suitable for cleaner material pellets such as injection leftovers, edge trim.

Blown Film and Recycling Machines - POLYSTAR | CHINAPLAS 2021

PRM Media Channel once again happy to share the great honor of the cooperation with CPRJ, the official media group of CHINAPLAS. Through this cooperation, we aim to provide insights into the Plastics and Rubber industry by the sharing of experts. In this video, we have invited Mr. David Lo, Chief Marketing Officer, to share his knowledge and the overview of Blown Film Extrusion Machines and Plastics Recycling Machines markets. POLYSTAR Machinery is one of the most famous manufacturers especially in recycling machines in Asia with more than 30 years of experience. Besides recycling machinery, the company also well known around the world with its blown film machine lines. Most of the customers of POLYSTAR buy several sets of blown film machines as well as recycling machines together to set a complete line in their factories and contribute to the circular economy. In this video, Daniel from PRM will be carrying the interview with the Chief Marketing Officer Mr. David Lo. During the interview, Mr. Lo is explaining the advantages for the customers having both blown film machines and recycling machines from POLYSTAR. The following, interview covers several topics including: 1. Advantages of POLYSTAR recycling and blown film machines 2. POLYSTAR contribution to circular economy and examples 3. Simplifying machine design for ease of use 4. Vision and development in 2021

2024 Expo Plasticos Guadalajara | HAO YU PRECISION MACHINERY INDUSTRY CO., LTD.

Join us as we interview Hao Yu Precision Machinery Industry Co., Ltd. at ExpoPlasticos 2024! We shine a spotlight on Hao Yu’s expertise in manufacturing PP/HDPE woven bag-making machines. With 26 years of local experience in Mexico, Hao Yu’s unique advantage lies in its direct communication with customers, ensuring tailored solutions to meet their needs. Their commitment to sustainability, combined with a strong willingness to engage directly with local buyers, enables them to deliver highly customized solutions that meet diverse needs.

Best Choice Of PET Extrusion Pelletizing Machine Line From Partico Machinery, Inc | PARTICO

Model no:HF-FTO-135 3 in 1- Flow Channel Pelletizing System Double Filters system: no.1 Double pistons(Back flush) no.2 CPF Spec:The dia of screw 135mm Output:500-600kg/hr Application:PET yarn, flakes, fiber, filament

Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

2023 IPF On-site Tour | PRM

IPF Bangladesh 2023 Bangladesh Exhibition covers "three main industries", including plastics, packaging and printing industries, creating opportunities for buyers and manufacturers to communicate with each other! Let PRM Alice show you the IPF Bangladesh 2023 exhibition!

IoT Injection Molding - Hot Runner Temperature Controller-TC50 | ARICO

【AUXILIARY EQUIPMENT IN THE VIDEO】 Hot Runner Temperature Controller-TC50 for Injection Molding Machines, IoT Solutions from ARICO. 【FEATURES】 HMI: 7" LCD display with touch panel Group setup function Mold Memory Power balance detection and display Synchronous heat up and cool down Self-diagnosis log Mold leakage detecting Injection machine connect for I/O function VNC function(option) 【SPECIFICATIONS】 Thermocouple type: J/K Temperature unit: ℃/℉ Heating mode selectable The maximum drive current is 15 ampere for each zone Temperature PID control Zero cross/Phase angle output trigger modes Auto detect the frequency of power source The current detect and display The output with auto/manual setting The soft-start for dehumidification Boost Standby Output mode: Stop/Manual/Slave/continually selectable when Thermo-coupler broken Overload protection for electric Overload protect for heating output The protect mode of power source when wrong input Auto shutdown when abnormal work on the module The fast fuse used to protect TRIAC 【ABOUT ARICO】 ARICO Technology and worldwide's rubber and plastic injection industry manufacturers have cultivated a long and stable co-operation relationship between us for many years. Founded in 1987, base on sophisticated manufacturing technology, and focus on the research and development and innovation of industrial control instrument technology. ARICO is not only good at producing customized precision Hot Runner Temperature Controllers and related application equipment but also provides high-quality Hot Runner Temperature Controllers with the most convenient setting mechanism, stable quality, at a reasonable price to manufacturers in Taiwan, China, the United States, India, Argentina, Israel, Mexico, Thailand, Malaysia, Southeast Asia, and other countries.

2023 Plast Eurasia Interview | WEI MENG

It's our great honor to interview WEI MENG and their Turkish agent in the 2023 PlastEurasia. Watch our video for more information!

Aluminum Foil Printing Techniques | WORLDLY

Have you ever wondered how essential it is for manufacturers and consumers to have the right packaging or sealing material on a decomposable product like medicine, snacks/drinks, or any other related product? By interviewing Klive from WORLDY, we have been explaining what kind of technical strengths Worldly has and they are capable of manufacturing and designing customization machines according to client's demand. Moreover, You will obtain the knowledge of the difference between plastic and aluminum foil to understand the applications of each materials.

Live Broadcast of High-quality MIT Suppliers | 2022 Taipei Pack

This year, Taipei Pack Exhibition will continue to exhibit various types of packaging machinery, materials, and logistics from different Taiwanese Manufacturers. Of course, PRM Media Channel will continue to attend this year's exhibition with LIVE STREAM video interviewing different manufacturers and giving you insights about their machinery technologies and functionality. Event: Taipei Pack Exhibition Date & Time: June 23, 2022 , 15:00 (GMT+8) Location: Taipei Nangang Exhibition Center, Hall 1 (TaiNEX 1) If you are looking for a packaging machine or packaging relevant suppliers, We, PRM MEDIA CHANNEL, invite you to watch this LIVE STREAM! Stay tuned!

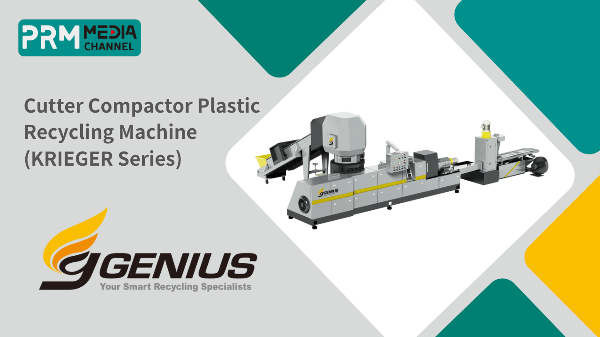

Cutter Compactor Plastic Recycling Machine (KRIEGER Series) | GENIUS

The KRIEGER series cutter compactor plastic recycling machine integrates crushing, extruding and pelletizing in one machine. A proprietary designed cutter compactor can compact the density of fluffy plastic film to flakes. It helps to increase the efficiency of extruder. After compactor, the materials are extruded to Genius patented universal joint pelletizing system. The universal joint pelletizing system can automatically adjust the distance when cutting the polymer to pellets. Significantly reduces manual adjustment error rates. After cooling, these pellets are sent to centrifugal dryer to remove moisture. A vibrator at next step removes powders or oversized pellets. Finally, recycled pellets can be reused in different fields, for example, blow film or injection molding industries. / Key Features of Cutter Compactor Plastic Recycling Machine / Energy cost saves up to 20% Only 1~2 operators are needed to operate the pp recycling machine. High-speed rotation operation makes the fluffy material compact. Simultaneous material dewatering. Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The temperature control is convenient, and the temperature of the crushing barrel is controlled in a stable manner. Provide customized recycling, sorting, feeding, degassing, filtering, granulating to storage and packaging systems.

Flat Yarn Extrusion Line & Raffia Tape Stretching Line | HAO YU

HAO YU Raffia Tape Stretching Line is designed for producing PP/HDPE raffia tape and flat yarn. 【Equipment Features】 - Capacity: 160 ~ 520 kg/h - Designed for making 500-1500 denier - Working speed 100-270 meter/minute - A screen filter changer - Rotary blade slitting system - Synchronized control electronic system - Low energy consumption - Less downtime - Reduce production loss 【Additional Features】 - European-made gearbox - T-die - Melt pump - Tape winder - Designed for making 2000-6000 denier upon special request 【Finished Products】 - Woven bag - Geotextile - Artificial grass - Carpet backing production 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

2024 CHINAPLAS Interview | ABIMAQ SINDIMAQ

It’s our great honor to interview Mr. Marcelo Zimmaro, Machinery and Accessories Sectorial Chamber for the Plastic Industry from ABIMAQ SINDIMAQ Brazil. In this interview, Jason asked him about ABIMAQ's services and business scope, his views on the economic situation in Latin America in recent years, and his expectations for this exhibition in China. Mr. Marcelo Zimmaro stated that their mission at the exhibition is to assist the Brazilian machinery industry in import and export activities, and they hope to find more allies and friends at this exhibition. For more detailed interview content, please stay tuned for the upcoming PRM reports. PRM is committed to collaborating with global media to bring more information about the world's plastics and rubber industry to everyone.

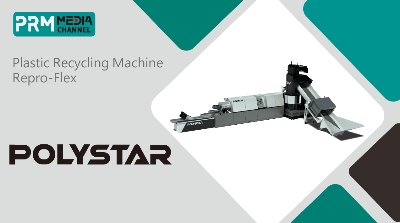

Plastic Recycling Machine, Repro-Flex | POLYSTAR

【Machine Features】 The one-step plastic pelletizing machine, Repro-Flex, combine cutting, extrusion, and pelletizing into one compact and efficient pelletizer line. The cutter-compactor of the plastic pelletizing machine prepares the plastic waste (PE plastic film and PP plastic film waste) into an ideal condition for the extrusion process and feeds the plastic waste directly into the extruder. This integrated system does not require a separate crusher, and therefore, eliminates the problem of inconsistent feeding, reduces space and labor costs, and has lower energy consumption. Simple in Design. Flexible in Operation. POLYSTAR is able to customize its machines regarding customers’ needs. How this pelletizing system works: 1. Feeding a. By belt conveyor Feeding of scraps is easy and automatically controlled depending on the amount of material input. b. By Nip roller Film-on-rolls can be fed at the same time. 2. Cutting and compacting The cutter compactor integrated cuts, dries, and compacts the material which enables a fast and stable feeding from the compactor directly into the extruder. 3. Degassing system The two-zone degassing can process plastic film with larger printed areas. 4. Filtration Screen change with a dual channel system for non-stop operation that also prevents plastic material from leaking. 5. Pelletization Water-ring pelletizing system, also known as hot die face pelletizing, the plastic comes from the recycling extruder and is directly cut by the rotating knives attached to the surface of the die head. 6. Final Product Round-shaped recycled pellets are produced and cooled inside the water ring immediately. 【Company Intro】 Headquartered in Taiwan, POLYSTAR has focused on the user-friendliness of its machines through continuous re-engineering, making recycling extremely “Simple” for its users – Easy operation and maintenance is what makes POLYSTAR the No.1 selling recycling machine today. Over the past 32 years, more than thousands of POLYSTAR recycling machines have helped worldwide plastic producers to reprocess their post-industrial (in-house) waste back into high-quality pellets in a simple and easy way.

Bag on Roll Making Machine-Draw tape Garbage Bag|Plas Alliance Ltd.

Are you looking for plastics and rubber suppliers for machinery, molds, raw materials, auxiliaries, and so on? Here is PRM-TAIWAN B2B Platform only one click away. Visit our website now and search for your Taiwanese suppliers. Learn More : • Bag on Roll Making Machine|Draw tape G... ------------------------------------ Draw tape garbage bags are advanced type of garbage bags which has strong tensile strength and puncture resistance, and controlled elongation for volume. The draw tape can be pulled and knotted for secure closure. Bag on roll are good and compact for transportation and end use for household consumers. - Bag making application - Draw tape garbage bag on roll - Folded draw tape garbage bag

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

Plastic Recycling and Blown Film Industry in LATAM | RRC Limitada (Polystar's Agent)

Recently, we had an interview with the General Manager and Auditor Accountant of RRC Limitada (Polystar's Chile Agent), a company based in Chile, which supplies South American countries with several kinds of plastics machinery including recycling machines, blown film extruders, bag making machines. They have vast experience knowing the machines and attending international exhibitions, which allow them to have a better understanding of how to assist a customer. RRC Limitada also represents Polystar Machinery, which is a successful Taiwanese manufacturer famous for recycling machinery and blown film extruders lines in many regional markets. Mr. Ricardo Rubilar and his son Rodrigo mentioned how their company's growth opportunities have increased in spite of the devastating impact pandemic has brought to the global economy. In the video, we will see how they explained the importance of having an agent in local markets can give a company greater selling results and enhanced services to local buyers.

Current Situation in Indian Extrusion Market | CCM India Interview

At the end of 2020, we had an online interview with Mr. Prashant Tanna from CCM India(Chichang Machinery India). At the interview, we have discussed various topics related to the plastics and rubber industry. Mr. Tanna sincerely replied to our questions and shared a deep insight especially about the plastics extrusion machinery market in India. We are grateful for the insight that we gathered from Mr. Tanna about the current situation of the Indian market, travel restrictions, benefits of having an agent in the local market, and so on. Let's watch the interview video together and leave your comment at the comment section!