Recycling Solutions for Packaging Industry | POLYSTAR Interview

At the recent TAIPEI PACK 2020, the famous packaging machinery exhibition of Taiwan, we have interviewed Ms. June Pei, from POLYSTAR. POLYSTAR is one of the most famous and leading recycling and blown film machines manufacturer from Taiwan, and has sold machinery in many countries around the globe. Ms. Pei shared her opinions and observations about the packaging industry, their recycling solutions related to the packaging industry, and also introduced the machinery they are showcasing at the exhibition. Moreover, she also mentioned the implementations to ease the effects of the pandemic on the business and the solutions they provide to their current and potential customers. Let's watch the interview video together and learn more. Thank you for your opinions and questions that you can leave as a comment. Remember to subscribe to our social media channels for the forthcoming interview videos and similar videos!~

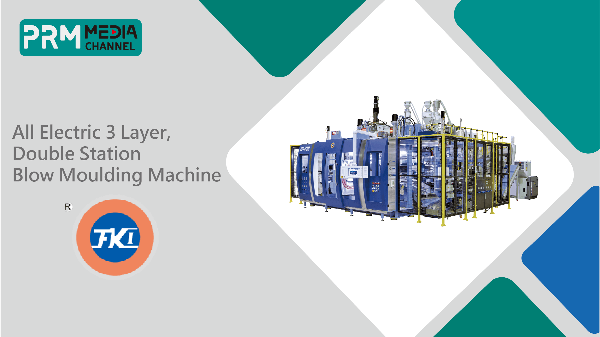

All Electric 3 Layer, Double Station Blow Molding Machine | FONG KEE

All Electric 3 Layer, Double Station Blow Moulding Machine for plastic bottle making Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system. Product (Jerry Can) 15lt/20lt Product Weight (N.W) 550g/680g Product Rate 270bph Avg. Power Consumption 67kW/102A Service Circuit Breaker 211kW/320A Machine Dimensions (LxWxH) 10x8x4.4m More information, please visit us at: www.fki.com

PP Woven Automatic Cutting-Sewing (Conversion) Line (CS-series) | BOTHEVEN

*Accurate bag length control by Servo Motor *Gripper bag transfer system, most advanced design *Maximum output 50 bag/min *Optional devise such as Gusset, Powder Brake, Easy Open function, Punch system, Liner Insert, Bottom Wrap *Union Special Sewing machine customized model available For more information, visit http://www.botheven.com.tw

Online and Offline Machinery Information for you! | PRM What To Say EP15

In this episode, we will uncover a series of online and offline information about machines and manufacturers related to the Plastics and Rubber Industry. Due to the pandemic many international exhibitions have been cancelled, postponed or even transformed into a digital exhibition. This has led us to become victims of the ones who attend international exhibitions. Nevertheless, for every challenging time there's always an opportunity to develop and become better. Following this philosophy we have brought a solution for the international companies in the related field who have been affected by the current situation. Check the video above to know more about the solutions we bring to the ones who are passionate about attending international exhibitions!

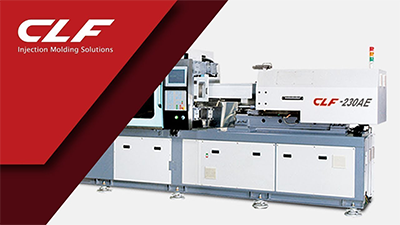

PET Preform Injection Molding Machine | CLF

PET Preform Injection Molding Machine for making big, medium and small mouth PET preform. CLF's Products: ⚫Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc. ⚫With our strength of machinery diversity, we could provide our customers the scheme of installment of whole factory buildings to achieve perfection of techniques and produc- tion capacity, and finally help them save the cost and shorten the investment cycle. Contact Information: https://www.clf.com.tw/en/contact.html

PRM at SINO PACK 2021 | Packaging Machinery & Materials Exhibition

Last week we attended our 2nd International Exhibition of 2021 and all thanks to our Marketing Team of PRM Shenzhen Branch!! Sino-Pack 2021 Exhibition on its 27th Edition, which was held by ADSALE, the same organizer of CHINAPLAS. The exhibition included: + Plastic packaging manufacturing machinery + Automated smart packaging machinery + And related machinery. To keep updated about the latest news of the Plastics and Rubber Industry, please follow us on our B2B Platform & Social Media Channels: PRM-TAIWAN Plastics and Rubber B2B Platform: https://bit.ly/3cdtMfF PRM-TAIWAN Facebook: https://www.facebook.com/PRMTAIWAN PRM-TAIWAN LinkedIn page: https://www.linkedin.com/company/prm-taiwan/

GOLD GREAT GOOD MACHINERY | PRM Media Channel Interviews at TAIPEI PACK 2020

At the recent packaging machinery exhibition, TAIPEI PACK 2020, we have interviewed Rita from GOLD GREAT GOOD MACHINERY. Rita shared her opinions and observations about the packaging industry, their implementations to ease the effects of the pandemic on the business, what kind of changes they made to sustain customer service efficiently for the PRM Media Channel audience. Moreover, Rita also introduces the machinery portfolio they have in the video. Let's take a look and share your opinions with us!~

TaipeiPLAS 2022 Live | PRM

The self-media era is coming! The plastics & rubber industry not only allows specific people or professionals to learn about this area. Throughout PRM's interview videos, we convey general information from plastics & rubber industry, environmental issues and social enterprise responsibility topics. ⏰ 10/1(Sat.) 15:00 (GMT+8) 【PRM exhibition insight interview】 We'll introduce the innovative machinery and techniques by interviewing exhibitors at TaipeiPlas 2022. To those who cannot attend the exhibition and overseas buyers, you can watch our on-site interviewing video to obtain the latest information.

Five Layer Blown Film Line | Multilayer Blown Film Machine | Blown Film Extruder - Kung Hsing

/ Kung Hsing Main Products / K.S. manufacture Agricultural Blown Film Machine, Inflation making machine, Flat Yarn making machine, Plastic strapping band making machine, Plastic Recycling Machine, as well as special design for all extrusion system machineries and whole plant projects. #KUNGHSINGPLASTICMACHINERY #BLOWNFILMLINE #MULTILAYERBLOWNFILM

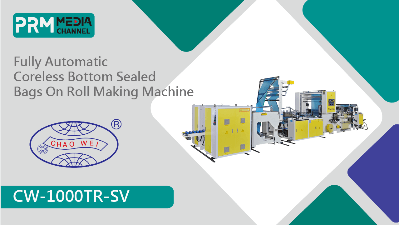

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

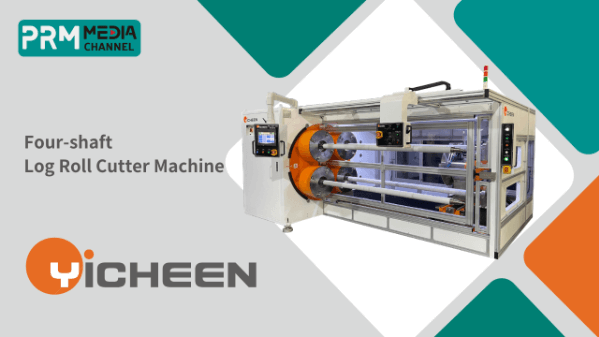

Automatic Log Roll Cutting Machine|Four-Shaft Log Roll Cutter | Yicheen

Automatic Log Roll Cutting Machine can be applied to cut rolls of various tape materials, such as double-sided tape, electrical tape, masking tape, construction tape, etc.. More product info: ???? https://bit.ly/3q8uLWw / Automatic Log Roll Cutting Machine Features / Cutting running is driven by AC motor with inverter control. Fast and stable to speed up & down. PLC control system Auto change cut size setting in the same shaft. Precise and smooth positioning. Multi-speed cutting rolls to improve operating efficiency and maintain high quality. The blade has different angle changes according to different materials, reducing the number of tool changes. / Advantages of Yicheen / Leading the industry in the research and development of the Die-Cutting Machine". In addition to the continuous improvement of technology, it has also developed a variety of Printing Machines, Laminating Machines, Cutting Machines, Sheet Cutting, Slitting Machines, and other equipment to provide complete plastics Processing equipment solutions. / links of Yicheen / Contact us: https://bit.ly/3q8KLaK Subscribe us: https://bit.ly/3wGjjU3 Product Info: https://bit.ly/3tU2QdK

Label Converting and Finishing System | YICHEEN

Machinery in the Video: Label Converting and Finishing System from YICHEEN Features: * Running operated by full rotary die cut method or intermittent die cut method. * Die is easy in change, save a lot of time in die mold adjustment. * Micro adjustable for the depth of die, able to dotted line cut/full cut/kiss cut procession. * Servo driver and HMI control system, easy in operation, to upgrade the speed and precision control. * Sensor detector and alert for broken material to reduce material lost. * Optional module for satisfying customized demands. * Optional Mechanism: EPC, Laminating, Die Cutting (Front & Back Die Cut), Liner Razor, Varnishing, Slitting/Cutting Sheet * Application: IML(in mold label), Self-adhesive Label, Sticker, Foam, IPO, Single/Double sided adhesive, Post-press finishing material, and so on.

How Machines Shape Every Shot: The Engineering of a Golf Ball

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

All-Electric Injection Molding Machine | TAIWAN KINKI

TAIWAN KINKI(TKC) is pioneer of Vertical Injection Molding Machines for Auto Industry, we were the first in the world to design and manufacture the 1st all-electric vertical injection molding machine for Taiwan and China. TKC works with a wide range of plastic injection materials and molded parts. 【All-Electric Vertical Injection Molding Machine Features】 Low Noise:All process-relevant movements (injection, mold open/close) are executed via electric motors, resulting in quieter and less noisy operation. High Efficacy:The electric unit is digitally controlled so that the mechanical operation is highly repeatable and precise, and the electrical drive enables the parallel movement of the machine, so the process is faster and more efficient. Save Water:Fewer components and oil need to be preheated than hydraulic injection machines, thus saving on cooling water usage. Power Green Energy:No hydraulic system is used, and energy is only used during machine movement, so it can save more energy and achieve power green energy.

Haitian Mexico Interview Part 2 | Solutions for Pandemic and Future Outlook

At the beginning of the month, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! In Part 2 of the video conference the Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the challenges they are having due to the pandemic, their solutions to overcome those challenges, and the current situation of COVID-19 in Mexico.

How 2025 U.S. Tariffs Will Reshape the Plastics Industry | PRM What To Say EP20

In this episode of PRM What To Say (EP20), we dive into the latest developments of the 2025 U.S. tariff policy and its profound impact on the plastics industry. What do the new 245% tariffs on China mean for global supply chains? How will Taiwan, Japan, Korea, and Europe be affected? Join us as we analyze the key changes, challenges, and future opportunities for plastics manufacturers worldwide. Topics Covered: U.S. reciprocal tariffs overview Strategic moves for manufacturers in 2025 Don't forget to subscribe for more insights on global trade, plastics machinery, and industry trends!

2024 CHINAPLAS Interview | ANIPAC

It’s our great honor to interview Mr. Aldimir Torres Arenas from ANIPAC He shared his insight for the China and Mexico market. Check our video for more information!

Assembling Video of Two Platen Injection Molding Machine - 3000TP | CLF

【ASSEMBLING VIDEO】 Two Platen Injection Molding Machine 3000TP from CLF. CLF is specializing in manufacturing plastic injection molding machines with super-large, high precision, and high performance.

High Speed Blow Moulding Machine | FONG KEE

High Speed Blow Moulding Machine-hbv-70-Fong Kee Specializes in High Speed Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest High Speed Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of High Speed Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

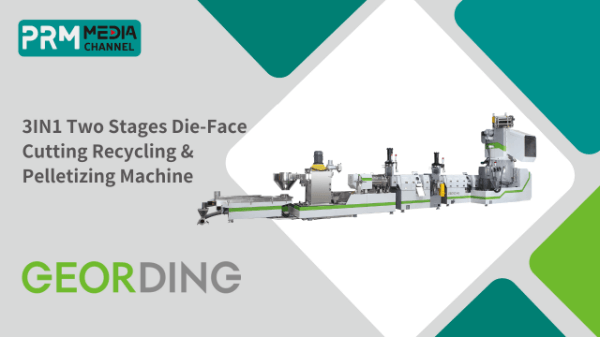

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine | GEORDING

3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine. The main businesses include: 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine and planning of entire plant’s equipment. While the demand for output and quality in 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine worldwide is increasing day by day, our determination for upholding the motto, "Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality 3IN1 Single Stage Die-Face Cutting Recycling & Pelletizing Machine products and services to higher standards.

VDMA Interview | Insight into the European Plastics & Rubber Market

We are excited to share the interview with Mr. Florian Mikulasch from Germany, who is the Marketing Analyst of VDMA (German Mechanical Engineering Industry Association). Mr. Mikulasch shared a clear insight into the German and European Plastics & Rubber Market, the current problems due to the pandemic, the second lockdown in Germany, and the solutions that companies and associations bring to life to ease the effects of the pandemic. Welcome to add comments and ask your questions in the comment section. Also, let us know about the video interviews (Such as which market?) that you would like to see on PRM Media Channel.

High Speed T Shirt Bag Making Machine|PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

ELS High Speed Rotogravure Printing Machine | WORLDLY-

High-Speed ELS Rotogravure Printing Machine WRP-HHI-1300-10C series | WORLDLY Machine Specifications - Max machine speed: 350 m/min - Web width: 1000 / 1200 / 1300 mm - Printing cylinder circumference: 350 - 900 mm - Material diameter: 800 / 1000 mm - No. Color: 10 colors