PRM What To Say

Original themed programs that include industry trends and insights allowing viewers to be up to date with the technology advances within the industry.

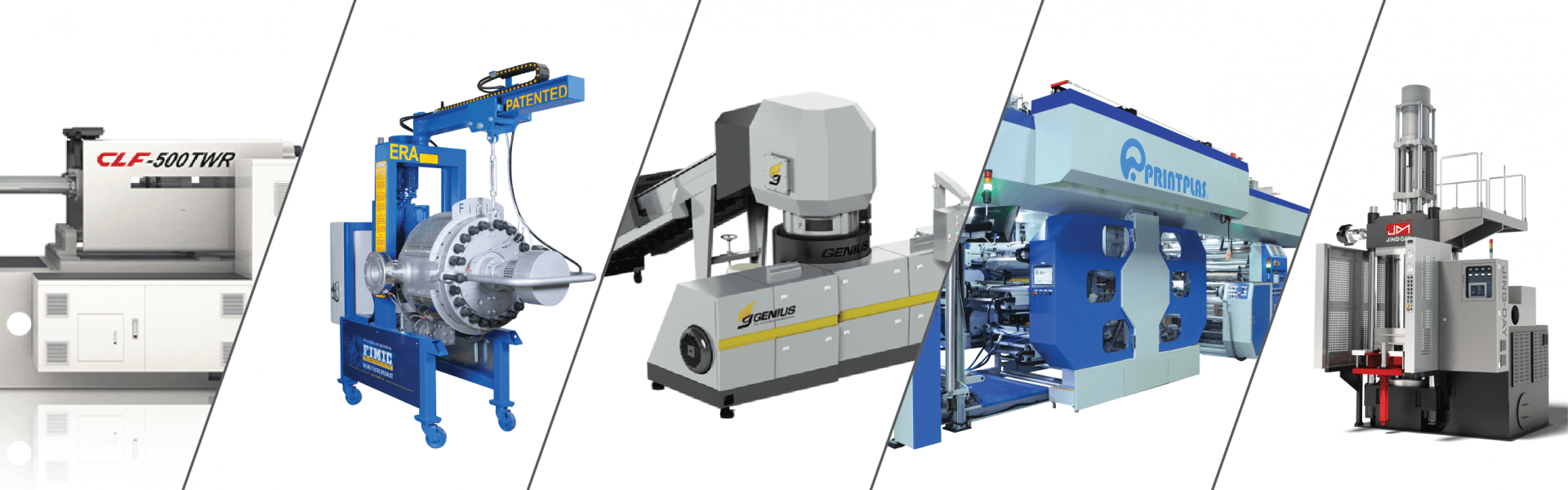

Every perfect shot starts with precision engineering. In this video, we take you inside the manufacturing journey of a golf ball — from the resilient rubber core to the durable plastic outer shell. Watch how advanced molding machines, material processing systems, and pad printing technology come together to shape every ball with accuracy and consistency. You'll see how multi-layer construction enhances performance, how dimples help stabilize flight, and how automation ensures uniformity from core to cover. Whether it's molding, printing, or aerodynamic design, every detail is crafted by machines built for precision. This is the engineering behind every swing. This is how machines shape every shot. Powered by Taiwan's leading machinery manufacturers, and brought to you by PRM-Taiwan — your trusted platform for discovering top suppliers and cutting-edge plastic & rubber processing solutions.

It's a great honor for PRM to share the observations of the Turkish market, including the economy, cultural influences, industry trends, investment opportunities, etc.

To know more about the Turkish market, watch the video!

Bangladesh has a rich, diverse culture. Its deeply rooted heritage is thoroughly reflected in its architecture, dance, literature, music, painting and clothing. For this episode, we’re going to talk about Bangladesh culture and tips on the operating market. Let PRM Cicilia share her insight and observation about Bangladesh Market!

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

Have you ever wondered why Taiwan is an automation and automotive parts manufacturing stronghold? In this episode, you will be explaining the first two streams, which are upstream and midstream, which are the initial points for the following procedure of the automotive industry.

In this episode, we will uncover a series of online and offline information about machines and manufacturers related to the Plastics and Rubber Industry. Due to the pandemic many international exhibitions have been cancelled, postponed or even transformed into a digital exhibition. This has led us to become victims of the ones who attend international exhibitions.

Nevertheless, for every challenging time there's always an opportunity to develop and become better. Following this philosophy we have brought a solution for the international companies in the related field who have been affected by the current situation. Check the video above to know more about the solutions we bring to the ones who are passionate about attending international exhibitions!

Climate Change, Extreme Weather, Greenhouse Gas Emissions and Plastic Reduction, those topics have been discussed for many years. What should we do to help the environment better? Starting not to use the air-conditioner, not to eat meats that might decrease a little.

Moreover, we could take action to use reusable materials, to reduce the frequency of ordering food delivery and use eco-friendly products. In this episode, we are conveying messages about the global warning to everyone that might lead you to think “What should we do for the Earth?”

In blow molding, hollow plastic components are formed through a producing process categorized into three main methods: injection, extrusion, and injection stretch blow molding.

In this episode of PRM What to Say, the plastic blow molding process is explained. Besides, we also mentioned some common benefits of the blow molding production method.

For more info and machine manufacturer info, you can refer PRM-TAIWAN Blow Molding Machine category at Blow Molding Machine Category

Since blow molding allows freedom for design and engineering, the range of applications that you can manufacture by blow molding is really wide. The automotive industry, Appliance components, Medical supplies and parts, Children’s toys, Packaging, Sporting Goods, and Industrial bulk containers are where we see blow molded products often.

The blow molding process is very suitable for automation. Especially using the robot technology for take out units and packaging offers the benefit of faster production. Besides that, you can also reduce labor costs by using automation.

In this episode, we will open a special page for TPU and TPE, TPR materials. Because there are several common confusions about them. Then, let’s understand the differences and fields of application of those innovative materials together.

【TPE/TPR】 Both TPE(Thermoplastic Elastomer) and TPR(Thermoplastic Rubber) belong to the family of Thermoplastic Elastomers, and there isn’t a defined industry standard to distinguish them. But, it is certain that TPE is made from SEBS, while TPR is made from SBS block copolymers.

[TPE/TPR Applications] TPE/TPRs are great for anywhere that flexibility, comfort, or cost savings are needed. They are a top choice for medical applications like surgical and dental tubing and also tubing used in the food/beverage industry.

【TPU】 TPU(Thermoplastic polyurethane ) is a soft polyether type polyurethane that is available in a range of hardness grades, which gives a diverse application range to TPU. There are two main types based on soft segment chemistry: Polyester-based TPUs, and Polyether-based TPUs.

[TPU Applications] With their resistance properties, TPU is superior for use anywhere that ozone, extreme temperatures, and high levels of abrasion are a concern. In addition to medical uses, TPU is also a popular material for sporting goods, tubing, wire, protective coatings, and more.

All those materials above are alternatives for natural rubber and are easy to manufacture. Moreover, those materials can be 100% recycled.

There are several types of printing techniques available for the plastic packaging industry. Such as flexo printing, offset printing, and screen printing. Although flexo printing is not a new technology, it is the most common method for packaging printing. Then let’s take a glimpse of the video to understand what flexo printing is and what makes it most preferable.

Flexographic printing is a technique that uses a flexible printing plate. The plates are wrapped around cylinders on a web press. The inked plates have a raised image and rotate at high speeds to transfer the ink through small holes from the anilox roll to the substrate, which is the printed surface.

So, what makes flexo printing the most common method? You will find 5 reasons why in the video.

Have you ever wondered how daily used plastic materials are made? Plastic materials are a part of our everyday life. Many of them are made by Plastic Injection Molding process. Starting from toothbrushes, cups, plates, automobile parts, hand tools, electric and electronic hardwares, and so on.

So, why is plastic injection molding commonly used for plastic materials manufacturing? We answered these questions and listed 6 benefits of the plastic injection molding process for you.

Come take a look at the video to discover more about the plastic injection molding machines and production process.

What are the biodegradable plastics? Are biodegradable plastics recyclable? Are biodegrdable plastics environmentally friendly? What are the types of biodegradable plastics? Where to use biodegradable plastics?

We heard your questions and made a research for you, looked for the answers of common questions about biodegradable plastics. We also evaluated difference and similarities of bio plastics and biodegradable plastics.

Let's take a look at the video and find out more about these two types of materials!