Issue 59

الاشتراك

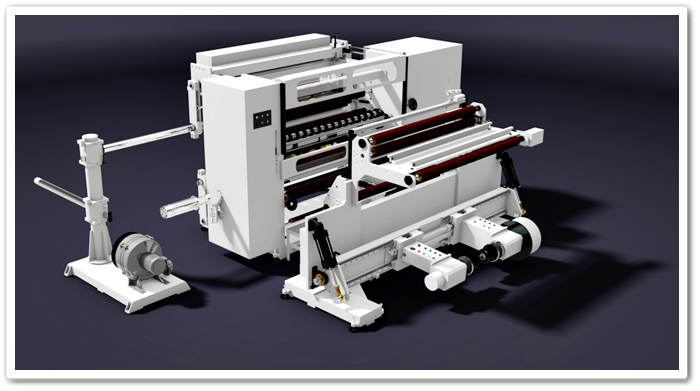

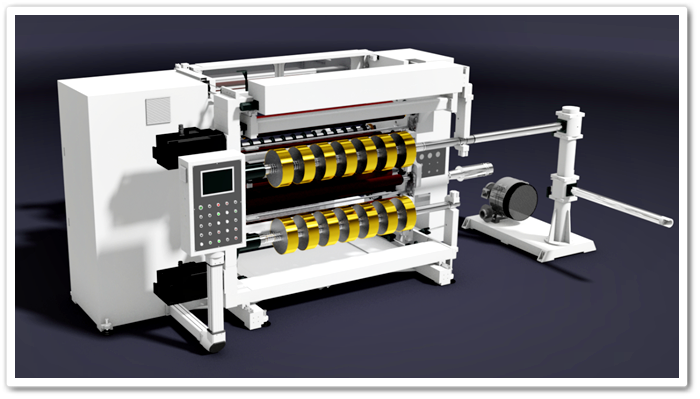

Great Features in One Solution – Auto taping and splicing High Speed Slitting Machine

The Top Manufacturer in Taiwan

No other companies in the manufacturing of slitting/bag-making machinery have longer history than Dahbah. Nor do any companies provide the slitting machinery that combines German automation technology. Utilizing Siemens PLC315F 2PN/DP with CU250S, the Ultima series slitting machine achieves 500 meters per minute, has a width of 1.5 meters, and is equipped with automatic laser core-alignment system and automatic rewind taping and splicing system.

A Winning Combination of Technology and Experience

Simple to operate and easy to understand

With Siemens human machine interface system on touch screen, the ease of operation is enhanced by intuitive screen page designs.

No other companies in the manufacturing of slitting/bag-making machinery have longer history than Dahbah. Nor do any companies provide the slitting machinery that combines German automation technology. Utilizing Siemens PLC315F 2PN/DP with CU250S, the Ultima series slitting machine achieves 500 meters per minute, has a width of 1.5 meters, and is equipped with automatic laser core-alignment system and automatic rewind taping and splicing system.

A Winning Combination of Technology and Experience

- The unwinding section is equipped with a splicing table, and a shaft-less unwind-stand with a hydraulic system that allows up/down and left/right movement for easier material loading performed by operators.

- The slitting section is equipped with razor and circular shear cutters that can be switched depending on the material characteristics.

- The rewinding section has a horizontal rewinding stand that uses linear movement; a cantilever-type differential air shaft with friction rings width of 19mm. Suitable for all single layer plastic films and laminated films.

- German-made automatic tension controller with load-cells and German-made static eliminator, to keep tension stability and final product appearance in tip top condition.

- German-made area safety scanner for the rewinding section, ensuring operator safety.

- The core-alignment system improves the efficiency of paper core positioning.

- The automatic rewind taping and splicing system reduces the machine downtime caused by material handling. This downtime includes, the process involving cutting, finished product, tape it with adhesive, unloading the product, loading new paper core, and taping the material to the new paper core. All this can be completed within two to three minutes.

- Combined with dual shaft unloading station, this allows operators to unload materials with ease, and they can perform packaging while the machine is running. Minimizing the machine downtime is the best way to make more efficient production.

Simple to operate and easy to understand

With Siemens human machine interface system on touch screen, the ease of operation is enhanced by intuitive screen page designs.

E-News Categories

بثق وخطوط البثق

- الهواء فقاعة الفيلم النتوء الخط

- الهواء فقاعة الفيلم النتوء الخط

- الهواء فقاعة ورقة المشارك النتوء الخط

- حقيبة صنع الآلات

- ضربة فيلم ماكينة

- ضربة فيلم إكسوسيون

- مهب فيلم ماكينة

- يلقي فيلم آلة

- آلة طلاء

- إبس / إيب رغوة ورقة خط البثق

- الطارد

- آلات الترقق

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- آلات حيدة البثق

- خط حيدة النتوء

- PET Strapping Band Extrusion Lines

- البلاستيك حقيبة صنع الآلات

- البلاستيك فيلم المشارك النتوء

- ماكينات تصنيع الأنابيب البلاستيكية

- البلاستيك أنبوب ماكينة

- بك خرطوم ماكينة

- سترو، صنع الآلات

- التوأم برغي الطارد

- التوأم برغي بثق

- المنسوجة حقيبة ماكينة

معدات إعادة التدوير للتجهيز المسبق

- زجاجة غسل الخط

- محطم

- المحبب

- بيليه

- إنتاج الكسور

- Pelletizing Machines

- بيت زجاجة إعادة تدوير الخط

- بيت الساخنة غسل الخط

- آلة تكوير

- معدات إعادة تدوير البلاستيك للتجهيز المسبق

- ماكينات إعادة تدوير البلاستيك

- البلاستيك آلة إعادة تدوير النفايات

- خطوط إعادة التدوير

- آلة إعادة التدوير

- التقطيع

- العصارات

- خط الغسيل

- معدات إعادة تدوير النفايات