ماكينات تصنيع المطاط

HOT NEWS

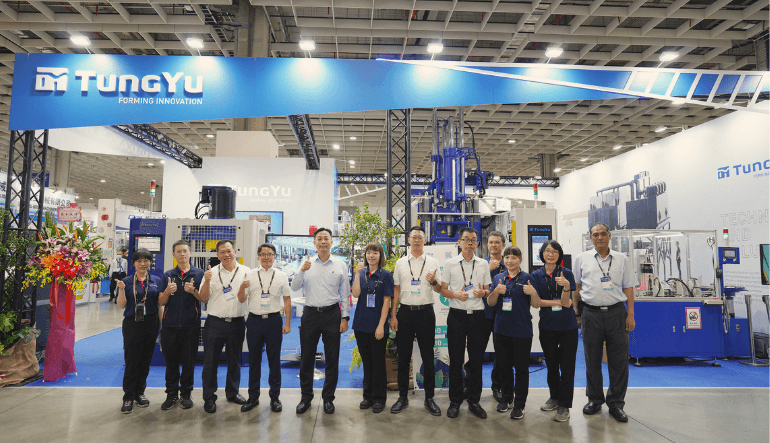

TungYu: Leading the Charge Toward a Greener Future

TungYu's Innovative Solutions Shine at TaipeiPlas 2024. TungYu, a pioneer in advanced manufacturing solutions, is thrilled to report the resounding success of our participation in TaipeiPlas 2024. Our cutting-edge technologies and commitment to sustainability captivated audiences and solidified our position as a leading force in the industry.

TungYu: Revolutionizing the Industry and Shaping a Greener Future

TungYu, a name synonymous with innovation in the rubber industry, is thrilled to announce our participation in two of the most prestigious industry events: RubberTech 2024 in Shanghai, China, and TaipeiPlas 2024 in Taipei, Taiwan. At TaipeiPlas 2024, TungYu will be focusing on the theme of "Shaping a Greener Future of Sustainable Forming Technologies.

TungYu Servo Press: Revolutionizing Manufacturing with Sustainable Power

Are you looking to enhance your manufacturing processes while minimizing environmental impact? TungYu's advanced all-electric servo press offers a sustainable and efficient solution. By replacing traditional hydraulic systems with high-performance servo motors, our servo press achieves significant energy savings and a reduced carbon footprint.

JingDay: A Pioneer in Rubber and Silicone Molding Technology, Forty Years of Expertise Yielding Diverse Applications

Rubber and silicone are no longer unfamiliar materials to most people. With their excellent elasticity, insulation, heat resistance, cold resistance, and outstanding electrical properties, it's easy to spot applications of silicone rubber in daily life. Since its establishment in 1983, JingDay Machinery, with its 40 years of knowledge and technology in rubber and silicone molding, has not only developed various specialized machinery for customers but also covered application fields such as automotive, motorcycles, 3C products, medical, sports products, and golf products.

JING DAY: The Strategic Role of Rubber Military Supplies in Modern Warfare

Rubber has long been a crucial material in various industries, and its significance extends to the military domain. From tires to protective gear, rubber plays a pivotal role in enhancing the effectiveness and survivability of armed forces around the world. In this article, we will explore the diverse applications of rubber military supplies and their strategic importance in modern warfare.

Advanced Technologies Could Process 20 Percent of U.K.’s Waste Tires

Norwegian rubber waste recycler Wastefront is set to open a $120 million plant in Sunderland, England, either late in 2024 or early 2025. The plant will utilize pyrolysis to convert end-of-life tires into tire-derived oil (TDO), which will then be refined into various combustion fuels, including diesel. Wastefront claims that the TDO produced will be cleaner than fossil diesel and cost-competitive, depending on the grade. It is expected to be cheaper than hydrotreated vegetable oil and similar biofuels.

Discovering Latest TungYu Solutions at 2024 Rubber and Plastics Exhibition

As part of its corporate development strategy, we will participate in the Global Rubber and Plastics Exhibition in 2024. This international exhibition brings together top companies and experts from the global rubber and plastics industries. Participation in this exhibition will provide TungYu with a platform to showcase its latest technology and products, engage in exchanges and collaborations with peers from around the world, and further enhance the company's international influence.

TungYu's Pathway To Net-Zero Emissions In 2050

TungYu is actively undertaking a comprehensive carbon footprint reduction plan to meet the challenges of achieving net-zero emissions by 2050. The initiative targets greenhouse gas inventory, product carbon footprint, and low-carbon and energy-efficient design throughout the product lifecycle, implementing a range of specific measures to achieve sustainable development goals.