BoReTech: Comprehensive Solutions for Plastic Recycling

BoReTech is at the forefront of global plastic recycling, providing cutting-edge technology and engineering solutions to enhance sustainability in the industry. With expertise spanning PET, PP, HDPE, and mixed plastic recycling, we offer a complete suite of innovative solutions designed to meet the evolving needs of recyclers worldwide.

Innovations in PET Bottle Washing & Recycling Technology

- Modular Design: Revolutionizing traditional systems. Our compact, modular PET bottle recycling line eliminates redundant processes, reducing plant footprint by 25% while maintaining full functionality.

- Automation & Smart Control: Intelligent automation minimizes inline labor costs and enhances production stability, driving down long-term operational expenses.

- Customized Solutions: Tailored plastic washing processes adapt to regional waste plastic bottles composition variations, ensuring optimal performance across global markets.

- Functional Machine Upgrade: Enhanced pre-washing, hot-washing, and impurity-removal systems boost recycled plastic rPET purity, reducing contaminants by 25% and easing downstream filtration pressure.

Breakthroughs in ES Process PET Bottle Recycling System

1. Integrated Pre-Washing System

- Combines bottle prewashing, label removal, and label separation in one compact unit.

- Achieves >99% label detachment and >95% label removal rates.

2. Optimized Hot-Washing Module

- Combines hot washing, friction washing, and inline chemical water circulation for 25% higher PET flake purity.

- Significantly extends filter life in pelletizing stages.

3. Label Removal

- Proprietary separation technology delivers 99% label removal accuracy with <1% material loss.

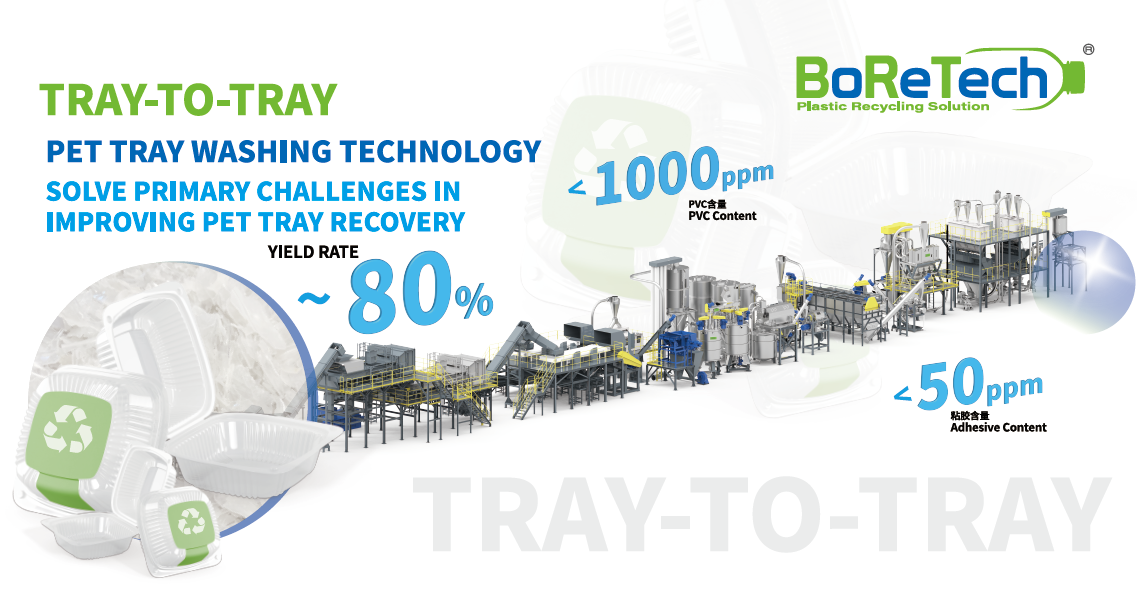

PET Tray Recycling & Washing

- Yield Enhancement Technology: A pre-treatment system with low-loss de-watering technology overcomes the problem of brittle materials being easily broken during washing, achieving a material yield rate of 80%, 30% higher than the industry average.

- Complete Material Loosening: High-efficiency pre-washing system ensures full loosening of high-compression-ratio material bales.

- Intensive Hot Washing: >90% removal and separation rate of adhesive labels and impurities.

- Mega Aspirator: Film labels and materials are separated with >99% accuracy and <1% flake carryover rate.

B2F (Bottle-to-Fiber) One-Stop Solution

- Solutions for various input material fed into extrusion, such as PET flakes, pellets, lumps, fiber waste,etc.

- More than 20 years of production and management experience in polyester staple fiber manufacture.

- One-stop solution from waste bottles to fiber production and engineering.

- In-house research and development of DCS control system.

- Familiar with R-PET fiber market and trade information.

Eco-spin Drying Technology

- Energy & Cost Efficiency : Reduces energy consumption and installed power by 20%, while cutting construction costs by 33%.

- Enhanced Productivity: Shortens melt residence time by 60%, increasing throughput and minimizing degradation (with vacuum system support).

- Superior Melt Quality: Significantly reduces molecular weight variations, improving spinning and drawing efficiency for higher end-product quality.

Rigid Plastics Recycling Line

- PP Tray Recycling: Designed to handle complex PP food packaging waste.

- Milk Bag & Film Washing: Efficient removal of contaminants from soft plastic materials.

- Fishing Nets & Rope Cleaning: Advanced washing technology recycles marine plastics into reusable materials.

PET Bottle-to-Bottle Recycling & Engineering

- High Efficiency & Stable Production: Combines parallel and conical twin-screw design for uniform plastication, high output, and stable pressure, ideal for high-viscosity and precision extrusion.

- Energy Saving & Eco-Friendly: Low-temperature, low-energy consumption design with vacuum degassing to reduce volatiles, suitable for heat-sensitive and high-purity materials.

- Flexible Control: Modular screw elements with adjustable shear and mixing intensity, adaptable to diverse processes like high-filling and devolatilization.

Join the Recycling Revolution

Discover how BoReTech’s innovative solutions can elevate your plastic recycling operations. Meet us at upcoming international expos or contact our team sales@bo-re-tech.com, for more information, to explore tailored strategies for your sustainability goals in plastic recycling industry.

|

|

CHINAPLAS 2025 in China Location: Shenzhen, China |