POLYSTAR Co-extrusion & Recycling: Making Plastic Film Sustainable

With the increasing concern over plastic waste and pollution, plastic bag manufacturers are looking for more sustainable production methods to diminish the negative effects of their plastic products. Co-extrusion and recycling are two techniques that are gaining popularity in the plastic film industry. In this blog, we will explore how co-extrusion and recycling can create a circular economy for plastic bag production and minimize waste.

The Environmental Impact of Plastic Bags

Plastic bags have become an integral part of our daily lives, but their extensive use has led to significant environmental problems. The wrong discarding and management of plastic bags have resulted in land and water pollution, threatening our ecosystem. As a result, manufacturers are turning to sustainable production methods like co-extrusion and recycling to diminish the negative effects of plastic bags.

Co-extrusion: Creating Multi-layered for Circular Plastic Bag Production

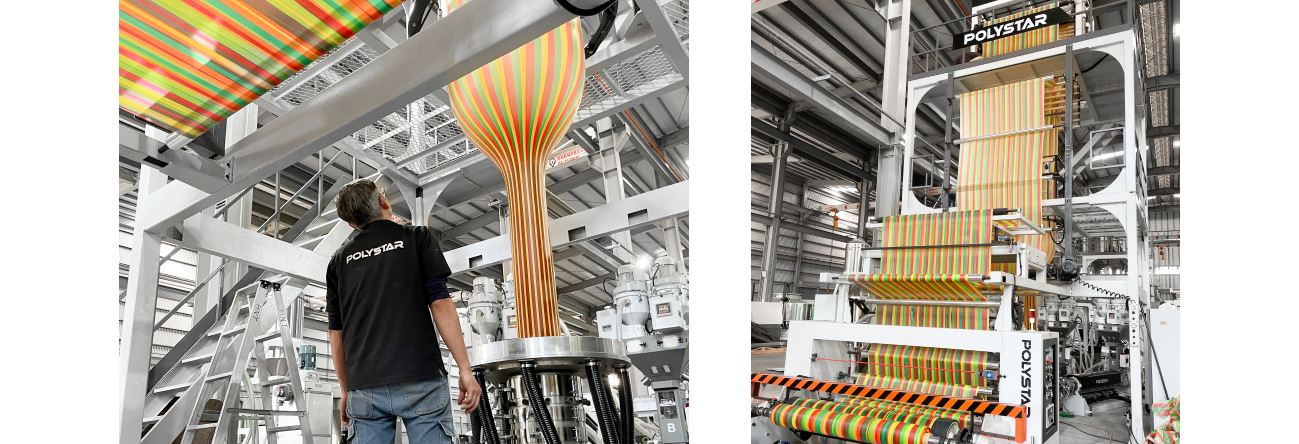

Co-extrusion is a manufacturing process that combines different plastic materials to produce multi-layered films or three-color films. Manufacturers can create films with customized properties like strength, flexibility, and durability, making them perfect for T-shirt bag production. Three layers and three-color stripes films are the most common products used for packaging goods in supermarkets and grocery stores, making them a popular trend in the plastic film industry.

(ABC co-extrusion 3 color multilayer blown film machine)

Recycling: Minimizing Waste and Costs in Plastic Film Production

Plastic film production generates a significant amount of waste in the form of defective film and blowing film take-up waste (lumps). To reduce costs and minimize waste, plastic film manufacturers install plastic pelletizers near their production lines. These machines recycle industrial waste and produce high-quality recycled plastic pellets, which can be reused in plastic film production or other plastic products.

POLYSTAR's Plastic Recycling Machines: Efficient and User-friendly

POLYSTAR Machinery offers a range of plastic recycling machines that can efficiently process many plastic materials, including HDPE, LDPE, LLDPE, PP, ABS, and PS. POLYSTAR machines are user-friendly and designed to reduce waste and production costs, making them ideal for manufacturers looking for a sustainable production method. We are committed to providing our clients with cost-effective and high-quality plastic recycling machines.

Want to know more: Does your factory have the right solution for your plastic waste?

(Efficient and user friendly plastic pelletizer easily recycled many materials like PE PP ABS PS)

POLYSTAR's Blown Film Machines: Producing High-quality Films with Flexibility and Cost-effectiveness

Our blown film machines produce high-quality HDPE, LDPE, and LLDPE films that are flexible and durable. Our extruders and co-extruders are engineered to process various types of materials, including recycled pellets, virgin materials, and CaCO3, making them highly cost-effective and flexible for manufacturers.

Want to know more: Co-Extrusion AB and ABA Blown Film Machine

The Importance of Co-extrusion and Recycling for Sustainable Plastic Film Manufacturing

The implementation of sustainable production methods like co-extrusion and recycling is vital for the future of plastic film manufacturing. By minimizing waste and reducing their reliance on virgin materials, manufacturers can contribute to creating a circular economy and reducing costs.

Working Towards a Sustainable Future with POLYSTAR Machinery!

At POLYSTAR Machinery, we are committed to delivering cost-effective and sustainable solutions to manufacturers looking to reduce their environmental impact. By adopting sustainable production methods like co-extrusion and recycling, we can create a sustainable future for plastic film manufacturing. Contact us today to learn more about our co-extrusion and recycling solutions and join us in building a better world.

Learn More