CHYI YANG: Transforming Waste into Gold, ABA Co-extrusion Machine Revolutionized Bag Manufacturing

International Plastics News for Asia | Chi-Chuan Cheng

國際塑料商情 亞洲版|鄭季顓

If plastic bags made from recycled materials can achieve the same quality as those made from virgin materials while significantly reducing production costs, they can catch the wave of environmental protection and be produced automatically. There's a simple but profound solution: ABA Co-Extrusion Technology; would you be interested?

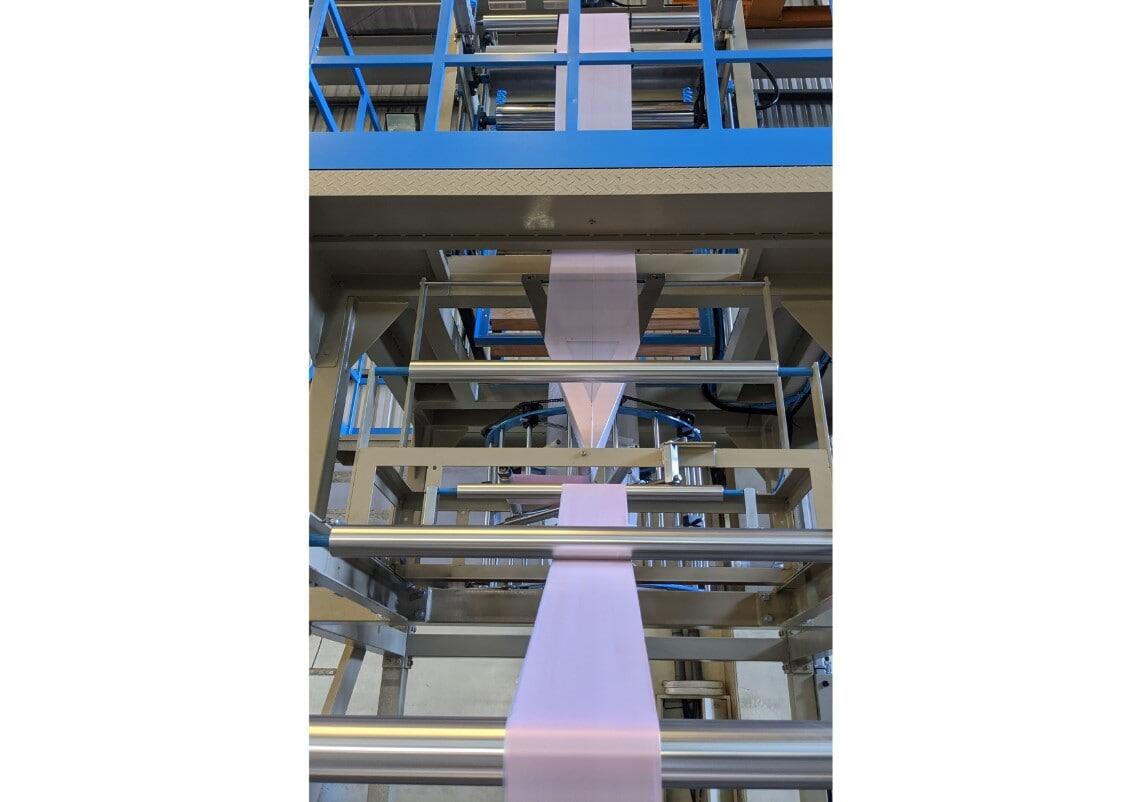

One Taiwanese manufacturer has achieved this! Originating from the production of hangers and masks, this Taiwanese factory recently successfully introduced Chyi Yang's ABA 3-Layer Co-Extrusion Machine to produce a variety of cleaning bags, including different sizes and scented garbage bags with flat and round bottoms, capturing a significant share of the bagging market in multiple regions. This has amazed current manufacturers and peers who are privately trying to uncover their secret to success. Everyone wants to know: "How did they introduce equipment and establish ABA Co-Extrusion production lines in such a short period?"

From Masks to Bags: The Green Evolution of Bag Manufacturing with ABA Technology

After extensive investigation by our editorial team, we found that the factory owner is a young man in his early 40s whose entrepreneurial journey has been marked by challenges and surprises. During the global COVID-19 pandemic, Taiwan experienced a mask shortage, prompting the owner to swiftly establish a mask production line to meet the sudden demand surge. Post-pandemic, with a global focus on environmental protection and the rise of the circular economy concept, the owner reconsidered his approach. "Even Coca-Cola can aim to produce bottles made from 100% recycled materials," prompted by the substantial plastic waste generated from mask production, he explored the idea of recycling mask waste into granules for plastic bag manufacturing. This led him to delve into manufacturers and ABA co-extrusion technologies capable of producing plastic bags from recycled materials.

This solution to the existing problem is termed the "ABA Co-Extrusion Process," which, though not entirely novel to the manufacturing industry, has gained traction in bag making. Unlike single-layer blown-film bag production, the ABA Co-Extrusion Process is gaining attention due to the complex marketplace dynamics. In recent years, the bag-making industry has grappled with rising costs, stringent quality requirements, and heightened environmental concerns. Consequently, solutions from ABA's blown film machines have revolutionized the traditional bag industry, offering advantages such as flexible cost control, enhanced film strength, increased production flexibility, improved efficiency, and reduced costs.

The unique die head design of the ABA co-extrusion machines offers producers cost management flexibility by incorporating an middle layer of recycled material or calcium carbonate compound, effectively reducing raw material expenses. This not only maintains competitiveness in raw material prices but also aligns with environmental trends. The resulting three-layer film is stronger than traditional single-layer bag-blowing machines, making it ideal for heavy-duty products like garbage bags, thus enhancing product competitiveness. This flexibility grants manufacturers a competitive edge, allowing them to tailor products to meet varying market demands. However, selecting a good ABA Co-Extrusion Machine can be challenging!

Cost-Effective Machine Selection: ABA Technology's Answer to Market Challenges

In business, reducing operating costs has always been a lifelong research topic for all business owners. The cost of an ABA Co-Extrusion Machine is almost equivalent to the combined price of two single-layer blown film machines. Therefore, why do some manufacturers still choose to invest double the amount in producing garbage bags from recycled waste? The editorial team pursued this topic and discovered Chyi Yang, a Taiwanese manufacturer that exports globally. Chyi Yang is a long-standing manufacturer of plastic film machinery, established in 1965, and has played a crucial role in the development of Taiwan's plastic machinery industry. So, Chyi Yang's senior director answered this question for us.

"First of all, the customer must have a clear product positioning," said the senior director of Chyi Yang. "As long as the customer's goal is to reduce production costs by working on raw materials, we leverage our experience to assist in the design planning to the best of our abilities. Chyi Yang has been able to assist her customers in producing blown film using less expensive recycled materials as if they were using new materials, and Chyi Yang has been

successful in doing just that!

"Fussy customers are the driving force behind Chyi Yang's progress," laughs the senior executive of Chyi Yang, "and I won't say who!" And "It's never good enough." "Stay motivated." Chyi Yang has embodied these spirits for many years, leading to a strong reputation in the international marketplace. As a result, Chyi Yang's customer base has expanded to every continent in the world.

Unlocking ABA Co-Extrusion Secrets: Chyi Yang, the Game-Changer for Bag Manufacturers

The owner of the ABA blown film bag manufacturing company expressed surprise at initially using general film waste for plastic bag production. Unexpectedly, the combination of "mask machine waste + ABA blown film equipment" yielded a high c/p value. This generated industry curiosity and media attention. Recognizing the importance of quality equipment, the owner prioritized investing in the best within budget. With the ABA co-extrusion blown film production line operating smoothly for over two years using recycled mask waste, the company plans to further expand production capacity by investing in another Chyi Yang machine this year.

Chyi Yang's ABA Co-Extrusion Machine has impressed industry experts with its remarkable speed of 110m/min, possibly surpassing single-layer production rates (although such high speeds are uncommon for most users). When the owner presented a video demonstration to Chyi Yang, even the senior director initially doubted its authenticity. "This accelerated video can't accurately represent our production capabilities to customers!" He remarked. However, it was later confirmed that the machine could indeed achieve such speeds, causing a wave of surprise in the industry and attracting media attention.

The Taiwanese owner takes pride in continuously pushing the machine beyond its limits, declaring, "I've invested in a quality machine!" Concurrently, Chyi Yang's ABA Co-Extrusion Machine, along with its 5 to 7 Multi-Layer Co-Extrusion Blown Film Machines counterparts, has garnered significant interest and positive reviews.

Chyi Yang's ABA Co-Extrusion Machine is a powerful tool for bag makers, providing unmatched flexibility in cost control, improved film strength, adaptability to diverse needs, and increased production efficiency. These advantages not only address immediate challenges for companies but also enhance the competitiveness of the entire industry, driving the bag-making sector toward a more sustainable future.

Learn more: