Eterlong in PLAST EURASIA ISTANBUL 2023 and Plastivision India 2023

Eterlong Co., Ltd. is pleased to participate in the annual events PLAST EURASIA ISTANBUL 2023 and Plastivision India 2023 with great enthusiasm. As our growing audience discovers the potential of impressive products demonstrations, fruitful buyer-seller meetings, and engaging discussions with industry professionals, People's expectations for the products and services Eterlong can offer are higher than ever.

We have noticed an increasing demand from customers for higher product quality and technical requirements. For Eterlong, this presents an opportunity to showcase our advantages in the competitive market.

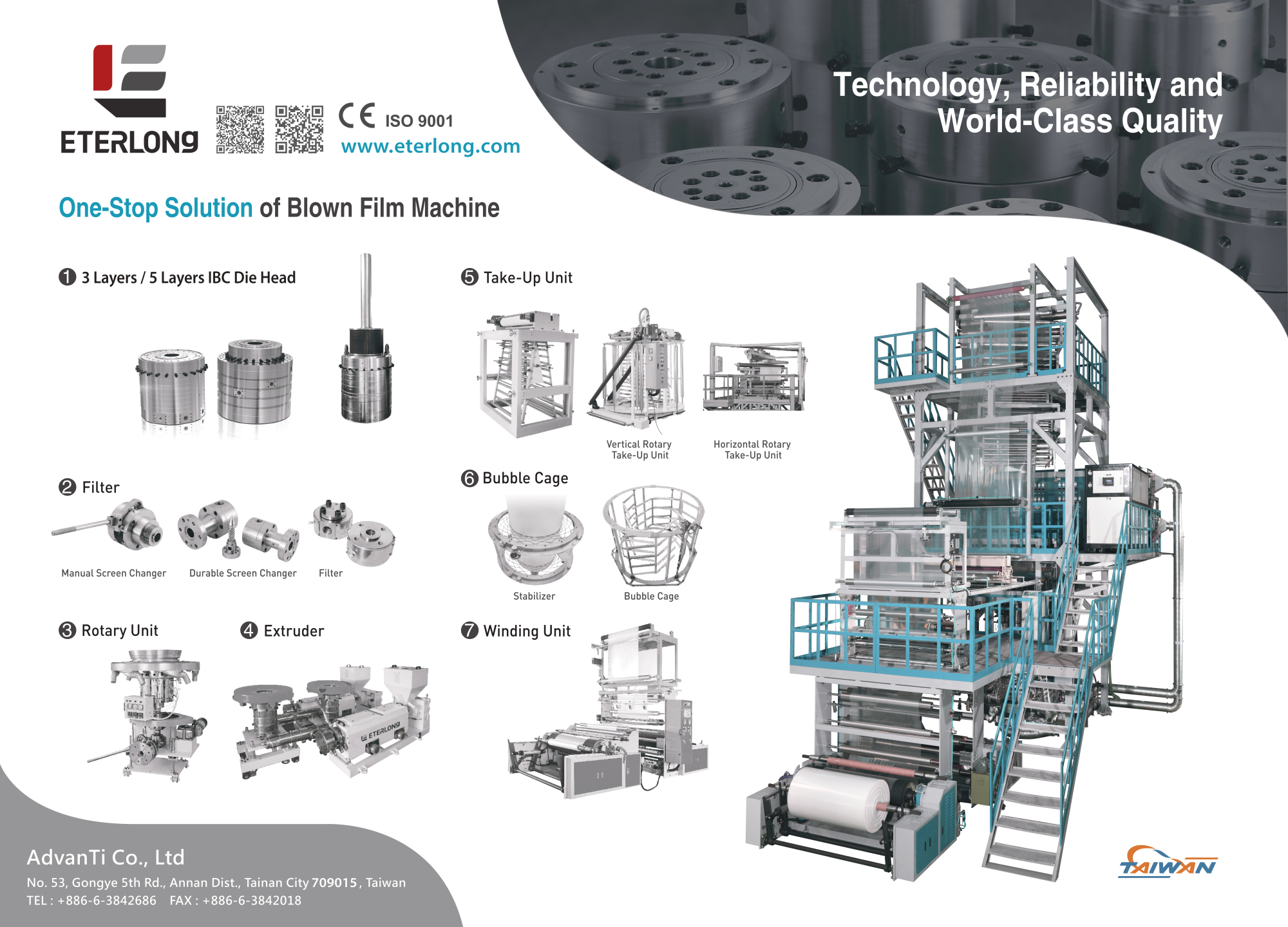

As well known in the market, Eterlong was formerly known as Hsin Long, a professional manufacturer of Die Head and key components for Blown Film Machines for over 50 years. Following the merger and expansion with AdvanTi Co., Ltd., a producer of titanium alloy products, Eterlong now represents our passion for advanced manufacturing of plastic products and our commitment to assuming the mission of being a global leader in Die Head technology.

Blown Film Industry Transitions in Recent Years

As an over 50 years experienced Blown Film Die Head manufacturer, Eterlong has its own perspectives after going through the transitions of the industry. Eterlong noticed the small changes in every detail which gradually brought big changes in the industry and even our daily lifestyle. By virtue of Sustainable Development Goals (SDGs), every company is dedicated to taking the responsibilities of ESG, which is a big move for environmental sustainability. Owing to this great move, the consumption habits have some imperceptible changes.

Here are the changes in the Blown Film industry Eterlong has observed through the interactions with customers and some international exhibitions they have participated in.

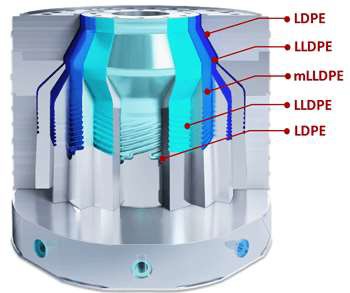

1. Raw Materials Used in the Making of Blown Films

In response to SDGs, more and more manufacturing companies delved into the usage of more green and biodegradable materials to make plastic films. This allows the plastic films to be decomposed or recycled after using and hence decreases the pollution to our Mother Earth.

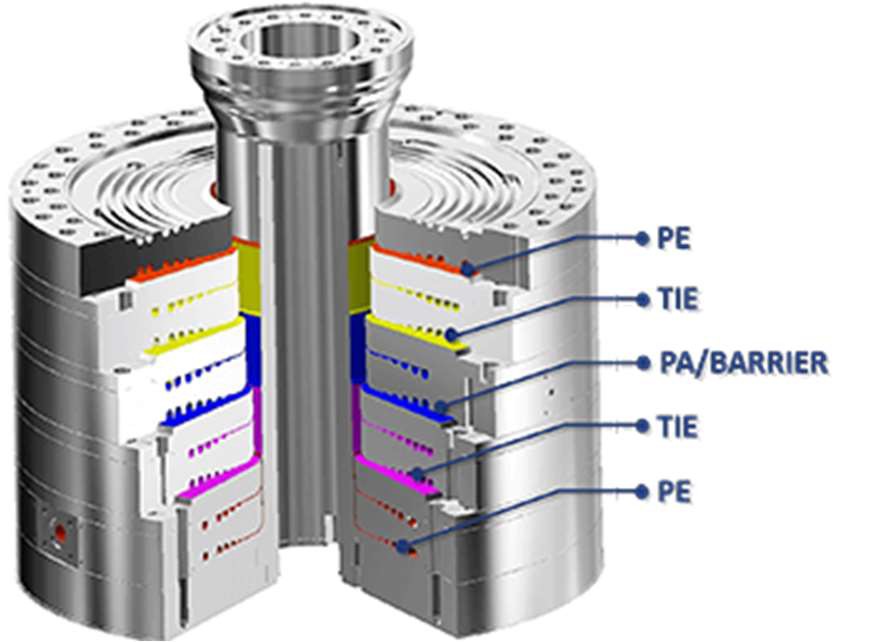

2. The Usage of Multi-Layer Blown Films is Becoming Mainstream Trend

There is a significant increase in the worldwide demands of the Multi-Layer Blown Film Line in recent years due to the benefits of multi-layer films such as production cost reduction, wider applications, etc.

3. The Most Affordable Multi-Layer Extrusion Die Head

In the past, Multi-Layer Extrusion Dies have large volumes but with continuous R&D, Eterlong’s multi-layer extrusion die head has incomparable features which brings a lot of benefits to our manufacturers. For instance, space-saving, cost-saving, reducing carbon, etc.

Exciting Innovations, Decreases Extrusion Multi-Layer Die Head Outside Diameter at about 15%

A usual Multi-Layer Extrusion Die Head with die lip of Φ400mm to Φ 500mm has outside diameter at about 1100mm to 1200mm. It is so indeed because of the previous application habits and the high degree of difficulty in the technical process. That is why a high-quality extrusion die head has a high cost since the quality of the extrusion die head manipulates the quality of the output films.

With dedications in skills improvement and product innovations, Eterlong is far more to be called as the best consultant in providing complete Blown Film Extrusion solutions. Eterlong understands sustainable transformation implies systemic innovation. Eterlong noticed the transitions far from about 3 years ago, hence we put unrested efforts in the innovations of Multi-Layer Extrusion Die Heads and accomplish with outside diameter not more than 1000mm. Eterlong outstanding multi-layer blown film extrusion die head can produce high performance films with decreased thickness variation, precise tolerances, without gel formation at their best assured quality.

|

|

|

Eterlong's Multi-Layer Blown Film Die Head

The Advantages Newly Developed Multi Layer Blown Film Extrusion Die Head

Here are some advantages of Eterlong's newly developed Multi-Layer Blown Film Extrusion Die Head:

1. Raw material consumption reduction

2. Heating time shorten

3. Carbon footprint reduction

4. Cost saving

5. Space saving

6. More convenient for manufacturers

Pursuit of Excellence—Global Outlook from Taiwan

As we joyfully welcome the arrival of 2024, we hereby declare the integration of our brand with our company name. Eterlong is our brand, and Eterlong Co., Ltd. is our company name. During this festive season, we would like to extend our best wishes for a peaceful Christmas and a happy New Year. May the festive season bring your business thrive and enjoy everlasting prosperity and longevity. Eterlong, Taiwan Brand, Taiwan Excellence.

بثق وخطوط البثق

- الهواء فقاعة الفيلم النتوء الخط

- الهواء فقاعة الفيلم النتوء الخط

- الهواء فقاعة ورقة المشارك النتوء الخط

- حقيبة صنع الآلات

- ضربة فيلم ماكينة

- ضربة فيلم إكسوسيون

- مهب فيلم ماكينة

- يلقي فيلم آلة

- آلة طلاء

- إبس / إيب رغوة ورقة خط البثق

- الطارد

- آلات الترقق

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- آلات حيدة البثق

- خط حيدة النتوء

- PET Strapping Band Extrusion Lines

- البلاستيك حقيبة صنع الآلات

- البلاستيك فيلم المشارك النتوء

- ماكينات تصنيع الأنابيب البلاستيكية

- البلاستيك أنبوب ماكينة

- بك خرطوم ماكينة

- سترو، صنع الآلات

- التوأم برغي الطارد

- التوأم برغي بثق

- المنسوجة حقيبة ماكينة

معدات إعادة التدوير للتجهيز المسبق

- زجاجة غسل الخط

- محطم

- المحبب

- بيليه

- إنتاج الكسور

- Pelletizing Machines

- بيت زجاجة إعادة تدوير الخط

- بيت الساخنة غسل الخط

- آلة تكوير

- معدات إعادة تدوير البلاستيك للتجهيز المسبق

- ماكينات إعادة تدوير البلاستيك

- البلاستيك آلة إعادة تدوير النفايات

- خطوط إعادة التدوير

- آلة إعادة التدوير

- التقطيع

- العصارات

- خط الغسيل

- معدات إعادة تدوير النفايات