Blown Film Machine vs. Blow Molding Machine: Difference and Comparison

Blown film machines and blow molding machines are easily confused by many people, but they are two totally different machines and function differently as well. In this article, we will be discussing each machine and how they operate.

What is a Blown Film Machine

Before we talk about blown film machines, we need to know what plastic films are.

Plastic film is a thin, flexible, and transparent sheet of plastic material. It is commonly used for packaging and wrapping food, as well as for various industrial and commercial applications. Plastic film can be made from a variety of materials such as polyethylene, polypropylene, PVC, polyester, and nylon. It is typically manufactured through a process of extrusion, where the plastic is melted and then forced through a die to form a thin sheet. Plastic film can be produced in different thicknesses, colors, and finishes, and can be used for a wide range of purposes including packaging products, protecting surfaces, insulating materials, and even as a component in electronic devices.

A blown film making machine is a type of manufacturing equipment that is specifically designed to produce these plastic films. The process of making a plastic film using a blown film machine involves melting plastic resin pellets and extruding them through a circular die to form a tube of molten plastic. This tube is then inflated like a balloon to a specific size and thickness, and as it cools down, it is flattened and wound onto a roll. This process is called blown film extrusion, and it is used to produce plastic film with consistent thickness and quality.

The blown film making machine plays a critical role in the production of plastic film, as it is responsible for the entire process from melting the plastic resin to winding the finished product onto a roll. The machine consists of several key components, including the extruder, the die, the air ring, the nip rollers, and the winder. Each of these components is designed to perform a specific function, such as heating and melting the plastic resin, shaping and cooling the molten plastic into a tube, and winding the finished film onto a roll.

Here are some blown film machines that are Taiwan manufacturers:

HDPE Single Head Type Super High Speed Blown Film Line

3-Layer Co-Extrusion Blown Film Machine

What kind of films can a blown film making machine produce

A blown film making machine can produce a wide range of plastic films, including:

1. LDPE (Low-density polyethylene) film: LDPE is a widely used plastic material for film production due to its excellent clarity, flexibility, and toughness. LDPE film is commonly used for packaging products such as bread, fruits, and vegetables, as well as for industrial applications such as construction and agriculture.

2. HDPE (High-density polyethylene) film: HDPE film is a strong and durable plastic material that is resistant to moisture and chemicals. It is commonly used for packaging products such as detergents, chemicals, and frozen food, as well as for industrial applications such as construction and geomembranes.

3. LLDPE (Linear low-density polyethylene) film: LLDPE film is a blend of LDPE and linear low-density polyethylene (LLDPE) resins. It is stronger and more puncture-resistant than LDPE film and is commonly used for packaging products such as meat, cheese, and snacks.

4. PP (Polypropylene) film: PP film is a tough and rigid plastic material that is resistant to heat and chemicals. It is commonly used for packaging products such as snacks, candies, and textiles.

5. PVC (Polyvinyl chloride) film: PVC film is a clear and flexible plastic material that is commonly used for packaging products such as meat, cheese, and medical supplies.

6. EVA (Ethylene vinyl acetate) film: EVA film is a soft and flexible plastic material that is commonly used for packaging products such as shoes and garments, as well as for industrial applications such as solar cells and photovoltaic modules.

These are just a few examples of the types of plastic films that can be produced using a blown film making machine. The type of film produced depends on the type of plastic resin used, the extrusion process, and the specific requirements of the application.

Mini HDPE/LDPE Blown Film Line

What is a Blow Molding Machine

Blow molding machines are specialized manufacturing devices that are used to produce a variety of hollow plastic products, including bottles, containers, and other similar items. The process of blow molding involves melting plastic resin pellets and then forcing the molten material into a mold cavity. Once inside the mold cavity, the plastic material is inflated using compressed air, which shapes it into the desired form of the product being produced.

Three Types of Blow Molding Machines

There are three main types of blow molding machines:

- Extrusion blow molding: This type of machine is used to create simple shapes such as bottles and containers with a narrow opening. The plastic material is melted and then extruded through a die to form a hollow tube or "parison." The parison is then captured in a mold and inflated with compressed air to take the shape of the mold. Extrusion blow molding machines are also used to produce larger products such as automotive parts, industrial containers, and tanks. However, for complex shapes or products requiring higher precision, injection blow molding or stretch blow molding may be more suitable.

Continuous Extrusion Blow Molding Machine for Large Containers

- Injection blow molding: This type of machine is used to create more complex shapes, such as medical and cosmetic containers. The plastic material is first melted in a separate chamber, then injected into a preform mold to create a small plastic piece that is then transferred to a blow mold to be inflated. Some examples of products that can be produced using injection blow molding include pharmaceutical vials, lotion bottles, and eye drop containers. Injection blow molding is also often used to produce small, single-use plastic parts, such as pipette tips and syringe barrels.

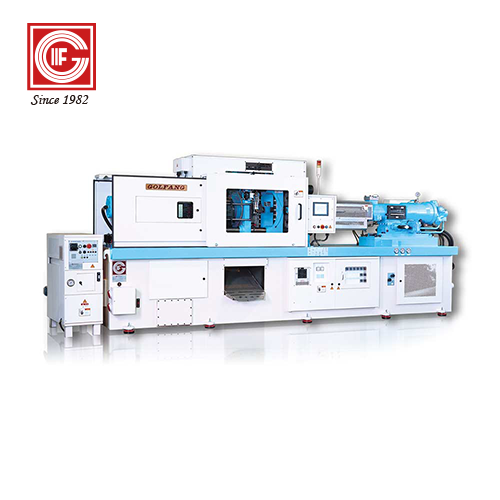

Single-Stage Injection Blow Molding Machine - IB Series

- Stretch blow molding: This type of machine is used to create high-quality, crystal-clear containers for products like juice, water, and carbonated beverages. In this process, the plastic is melted and formed into a preform, which is then stretched and inflated inside a blow mold to create the desired shape. Stretch blow molding is particularly useful for producing products with intricate shapes, such as custom-designed bottles with unique curves or angles. This process can also be used to produce lightweight containers that are durable and resistant to impact and breakage.

PET Sretch Blow Molding Machine - Small Capacity of Diversity Bottle Production Line (LM Series)

Blow molding machines are widely used in the manufacturing industry because they offer several benefits, including high production speeds, accuracy, and efficiency. They can also produce a wide range of products, from small bottles to large tanks, and can be customized to meet specific production needs. Additionally, blow molding machines require skilled operators who understand the process, materials, and equipment to ensure that they operate smoothly and produce high-quality products.

In conclusion, blow molding machines are an essential tool for manufacturing a range of plastic products, and their versatility and efficiency make them a popular choice in the industry.

|

Feature |

Blown Film Machine |

Blow Molding Machine |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

In conclusion, blow molding machines and blown film machines are two entirely different machines, not only do they function differently, but produce totally two different industrial products. Blow molding machines are used to produce hollow plastic products such as bottles and containers, while blown film machines are used to produce flat plastic films of various thicknesses. The manufacturing process and the components used in each machine are also different, making them specialized tools for different applications in the manufacturing industry.