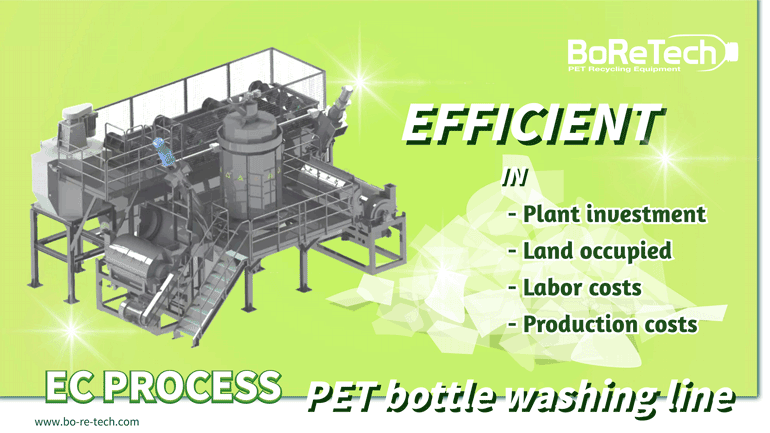

BoReTech: EC WASHING PROCESS – OPEN THE NEW WAY TO PET BOTTLE RECYCLING WORLD

The global PET bottle recycling rate is approximately 50%, but it still needs to be improved. With restrictions on the import and export of plastic waste in various countries around the world, the local plastic recycling model is imperative. The demand usage for recycled PET by global brands has increased, so the recycling rate of waste PET must be increased year by year.

BoReTech took two years to investigate and analyze the variation tendency in global PET bottle packaging and composition of waste PET bottle bales. As a professional supplier of recycling equipment that has been deeply involved in the plastic recycling industry, BoReTech has proposed how to reduce the concentration of such a huge PET bottle recycling process due to the global land area is gradually decreasing, prompting us to consider environmental friendliness to reduce equipment footprint and equipment production energy consumption, which responding to global energy conservation and emission reduction, and reducing carbon footprint.

Compared with the traditional recycling process, the EC washing process PET bottle recycling system by BoReTech has greatly reduced land and plant investment, and at the same time, the investment in production costs and the manpower requirements are relatively reduced.

For the developed countries and regions, tight land, and high labor costs, the EC washing process has significant advantages. The EC washing process has 3000 kg/h and 6000 kg/h input capacity as the standard design. Compared with the same input capacity of the traditional process, the equipment land occupied will be reduced by half, and the final product rPET flakes quality is the same, which can be directly applied in bottle-to-bottle production and micro-denier filament production. The EC washing process adopts a modular design concept to reduce the equipment maintenance points, reduce the failure rate of equipment operation, and be conducive to the unification and standardization of spare parts.

To emphasize the concept of environmental protection, the water circulation system of the EC washing process will pass through the online fine filtration system to achieve more than 50% of the water that can be reused in the washing process. At present, the EC washing process technology has been successfully developed and internal trial running. BoReTech is expecting to launch on the market next year.

For more details about PET bottle washing line, please visit:

Official Website

Official Websitewww.bo-re-tech.com

BoReTech on PRM-TAIWAN

https://www.prm-taiwan.com/com/boretech.html

E-News Categories

بثق وخطوط البثق

- الهواء فقاعة الفيلم النتوء الخط

- الهواء فقاعة الفيلم النتوء الخط

- الهواء فقاعة ورقة المشارك النتوء الخط

- حقيبة صنع الآلات

- ضربة فيلم ماكينة

- ضربة فيلم إكسوسيون

- مهب فيلم ماكينة

- يلقي فيلم آلة

- آلة طلاء

- إبس / إيب رغوة ورقة خط البثق

- الطارد

- آلات الترقق

- Extrusion Lines For Filaments and Yarn

- Extrusion Lines For Pipes and Profiles

- آلات حيدة البثق

- خط حيدة النتوء

- PET Strapping Band Extrusion Lines

- البلاستيك حقيبة صنع الآلات

- البلاستيك فيلم المشارك النتوء

- ماكينات تصنيع الأنابيب البلاستيكية

- البلاستيك أنبوب ماكينة

- بك خرطوم ماكينة

- سترو، صنع الآلات

- التوأم برغي الطارد

- التوأم برغي بثق

- المنسوجة حقيبة ماكينة

معدات إعادة التدوير للتجهيز المسبق

- زجاجة غسل الخط

- محطم

- المحبب

- بيليه

- إنتاج الكسور

- Pelletizing Machines

- بيت زجاجة إعادة تدوير الخط

- بيت الساخنة غسل الخط

- آلة تكوير

- معدات إعادة تدوير البلاستيك للتجهيز المسبق

- ماكينات إعادة تدوير البلاستيك

- البلاستيك آلة إعادة تدوير النفايات

- خطوط إعادة التدوير

- آلة إعادة التدوير

- التقطيع

- العصارات

- خط الغسيل

- معدات إعادة تدوير النفايات