تصنيف: نظام تغيير سريع للوقود

بلد: تايوان

هاتف: 886-4-8282758

فاكس: 886-4-8282768

الشخص الذي يمكن الاتصال به: Garnett Chang

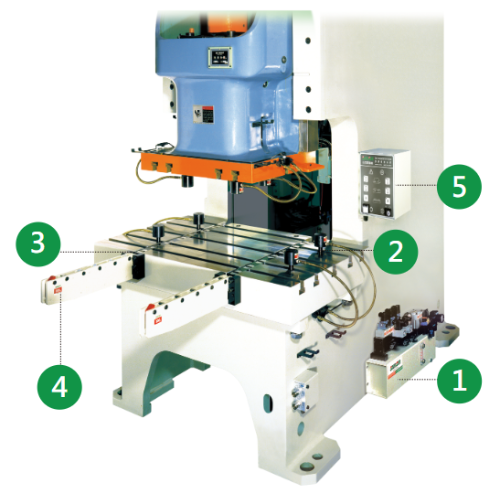

It is an era for making high frequency of die changing with multiple patterns and small quantity. In order to save die changing time and ensure operational safety, it is just in time to apply Quick Die Change System.

APPLICATION

- Press & Hydraulic Press

- Different Automatic Machine & Clamp System

MODEL CA - MODEL SELECTION

.png)

| ① | ② |

|---|---|

| Capacity of clamp : 1~25(25tons) |

EMPTY: Standard type C:Pneumatic cylinder movable type B:Fixed type V:Temperature -resisting type |

*Please indicate the size of T slot (a,b,c,d) and the thickness (H) of the template for the die when purchasing.

L: Template's length for clamp

Unit:mm

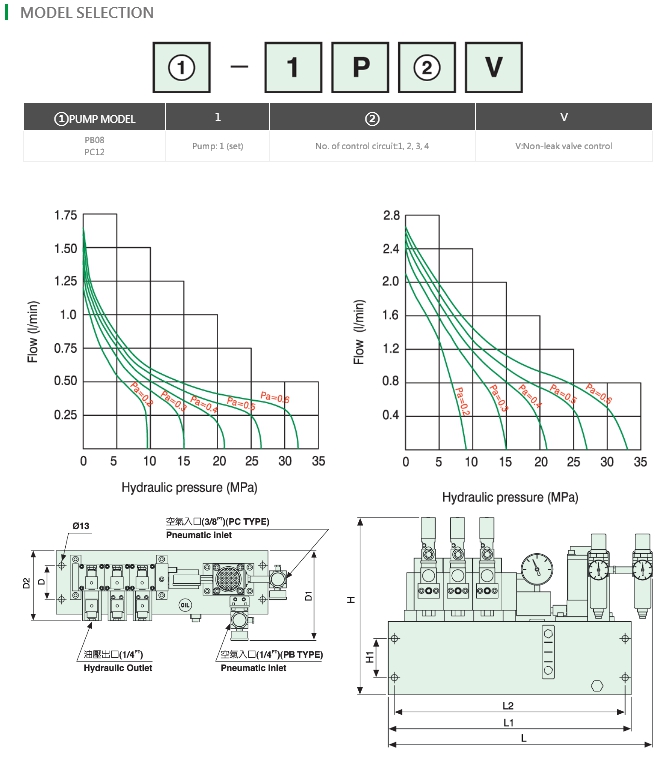

MODEL CB - MODEL SELECTION

.png)

| ① | ② |

|---|---|

| Capacity of clamp :1~25(25tons) |

EMPTY: Standard type C: Pneumatic cylinder movable type B: Fixed type V: Temperature -resisting type |

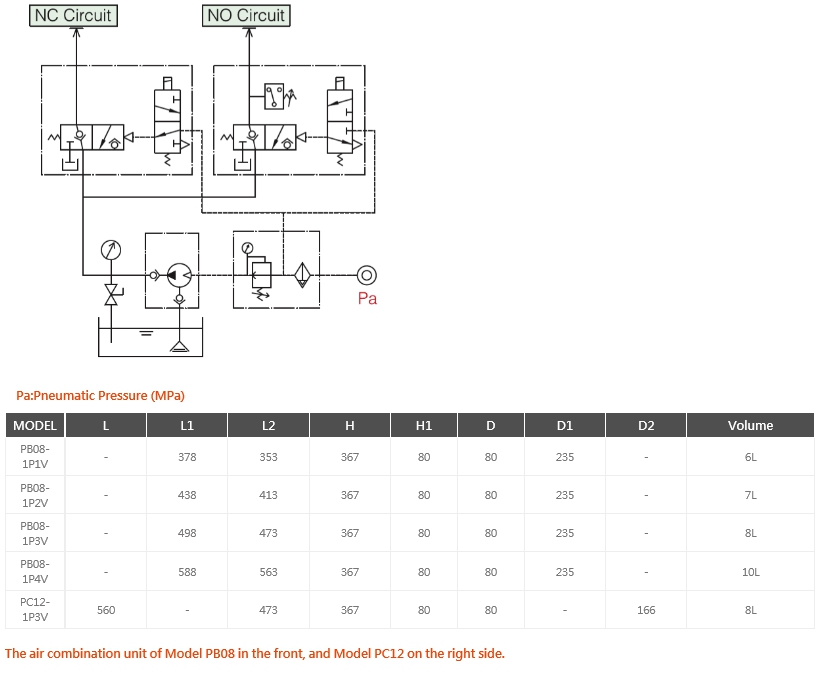

MODEL CD ( AUTO SLIDE CLAMP ) - MODEL SELECTION

| ① | ② | ③ | ④ | ⑤ | ⑥ | ⑦ |

|---|---|---|---|---|---|---|

|

Capacity of clamp: 4.6.10 (tons) |

S:stroke 400~1300 |

Teminal box R:right side L:left side |

H: Die template thinckness |

P: Distance between seat & Slide |

V: Proximity switch voltage 1. AC90~240V(2-Wire) 3: DC10~30V(NPN, 3-Wire) 4: DC10~30(PNP,3-Wire) |

Solenoid valve: 0: No solenoid 1: AC110V 2: AC220V 3. DC24V |

-型式選定2-2.png)

-型式選定2-1.png)