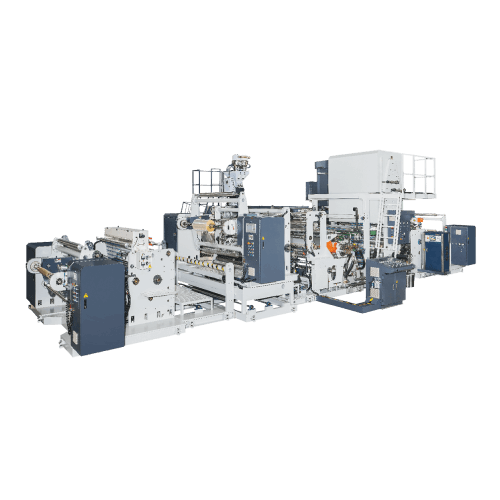

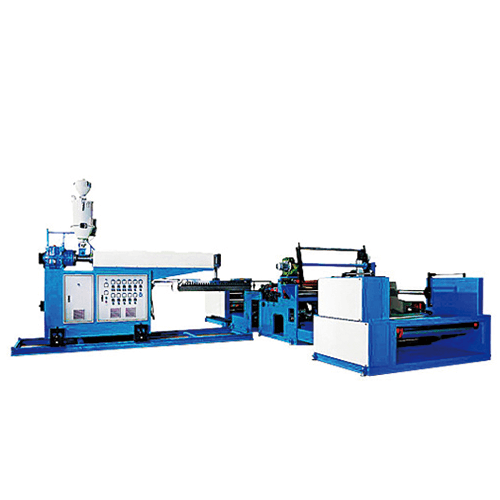

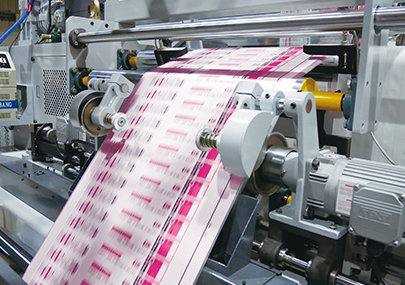

The main function of the LMBO series is to make two types of film. First is PP tubular woven cloth double side lamination. PP Tubular woven cloth goes through turn bar device, then the two side is completed laminated at the same time. Second is lamination by double side of PP tubular woven cloth and BOPP printing film, and the main feature is that the two sides of the printing point can reach automatic peering.

- Production speed is divided into 100 m/min and 180 m/min models

- Special screw design to produce high quality and stable discharge.

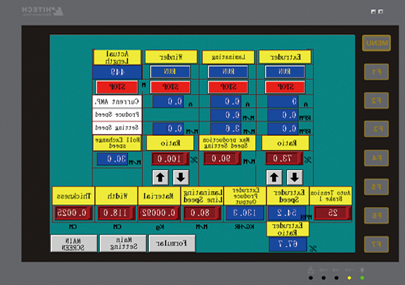

- PLC programing and human machine interface makes more convenient to set the film thickness, speed synchronous control, and automatic roll change

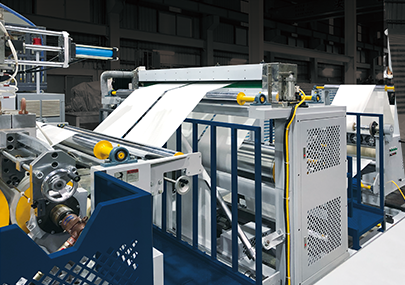

- Unwinder is equipped with automatic cloth connect, and the winder can be used for meter set automatic cloth change function

- The unwinder and winder through the automatic tension control system, which can keep the smoothness of cloth

- Machine customization

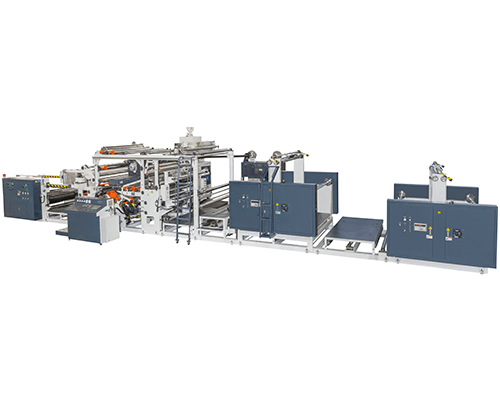

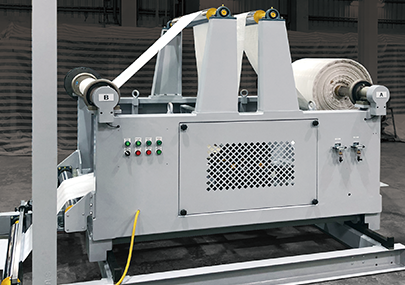

The unwinder of BOPP sandwich laminating machine, and the take up motion of unwinder can ranged into two types which are

EPC automatic edge cutter device, color film can effectively align and adjust the trim size

PLC programing and human machine interface with interlocking operation and operating data memorize

Teflon tape device with belt type, two side or unilateral adjustments

PP Surface treatment corona and PP woven bag turn bar device.

The unwinder is equipped with cloth roll missing cloth detection and automatic roll change design, make operations more

MAGUIRE blender(optional), and its function is to automatically cut and mix according to the proportion of raw materials

|

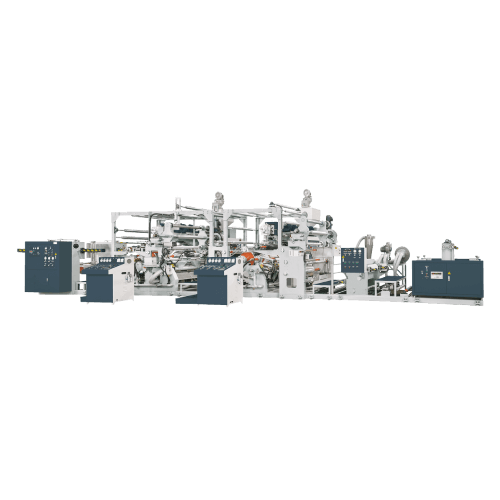

ITEM/MODEL |

TY-LMBO90-16-08SWD |

TY-LMBO95-18-09SWD |

TY-LMB110-18-09SWD |

TY-LMBO115-18-09SWD |

|

Extruder Max. Capacity |

200 kg / hr |

240 kg / hr |

360 kg / hrv |

420 kg / hr |

|

Max. Line Speed |

100 m / min |

100 m / min |

180 m / min |

180 m / min |

|

Coating Thickness |

0.018 mm - 0.05 mm |

0.018 mm - 0.05 mm |

0.018 mm - 0.05 mm |

0.018 mm - 0.05 mm |

|

Screw Diameter / Multiple |

90 mm / 32D |

95 mm / 32D |

110 mm / 32D |

115 mm / 32D |

|

T-die Width |

1650 mm |

1850 mm |

1650 mm |

1850 mm |

|

Coating Width |

350 mm - 680mm |

350 mm - 780 mm |

350 mm - 680 mm |

350 mm - 780 mm |

|

PP Tubular Colth Weight |

60 - 100 gsm / m2 |

60 -100 gsm / m2 |

60 - 100 gsm / m2 |

60 - 100 gsm / m2 |

|

L x W x H |

13000mm × 11000mm × 3600mm |

13000mm × 11500mm × 3700mm |

14000mm × 12200mm × 3900mm |

14000mm × 12800mm × 4000mm |