Forwell specializes in the production of Automatic Clamp Systems with a wide range of models specially designed to fit your dies and plates. With over 20 years experience in the industry you can rest assured that Forwell will deliver the highest quality clamps for your machining operations.

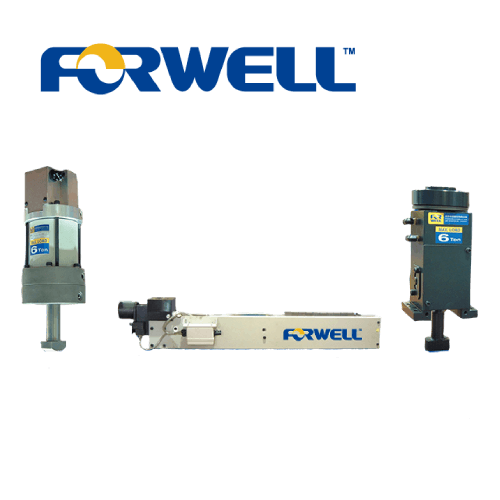

There are a wide range of different models available but the three most popular automatic clamping systems are the TAX Pneumatic Type Clamp System, the TR 90° Rotating Die Clamp and the TS Swing Type Clamp.

- Very secure clamping systems

- Wide range of different models

- Greatly reduces die and mold change times

| Before |

After |

| 01 Manual Operation |

Automation |

| 02 While Die/Mold changing, it takes long time and manpower to tighten. |

Only touch the buttons on the control panel. |

| 03 The tightening force will be different by different operators. |

The clamping force is the same. Increased safety. |

| 04 Operators waste much manpower, increased injury happened. |

By control panel, operators save manpower and decrease injury happened. |

| 05 No alarm notification while the screws are loosing. |

With alarm device, the machine will stop immediately. |

Forwell specializes in the production of Automatic Clamp Systems with a wide range of models specially designed to fit your dies and plates. With over 20 years experience in the industry you can rest assured that Forwell will deliver the highest quality clamps for your machining operations.

There are a wide range of different models available but the three most popular automatic clamping systems are the TAX Pneumatic Type Clamp System, the TR 90° Rotating Die Clamp and the TS Swing Type Clamp.

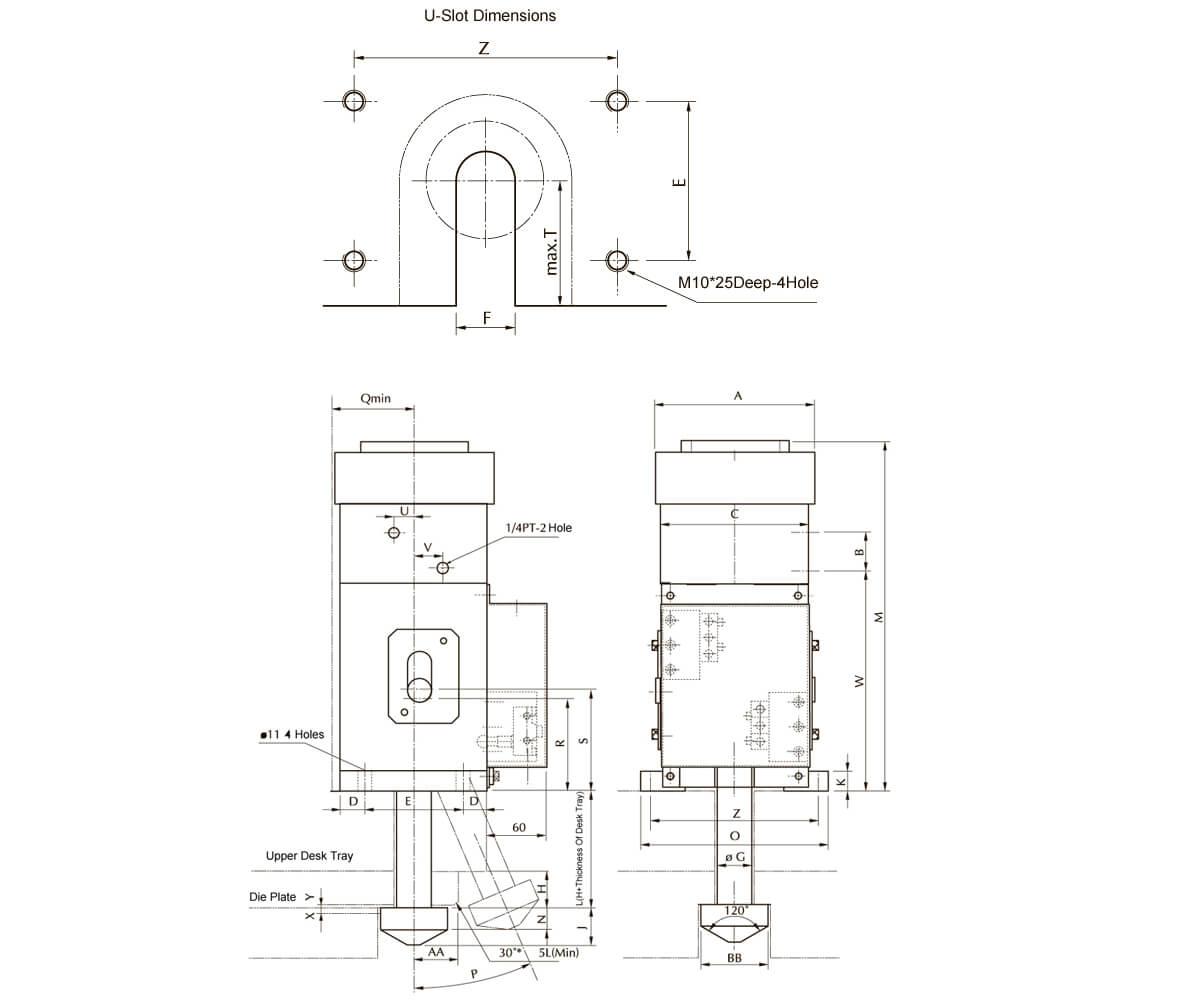

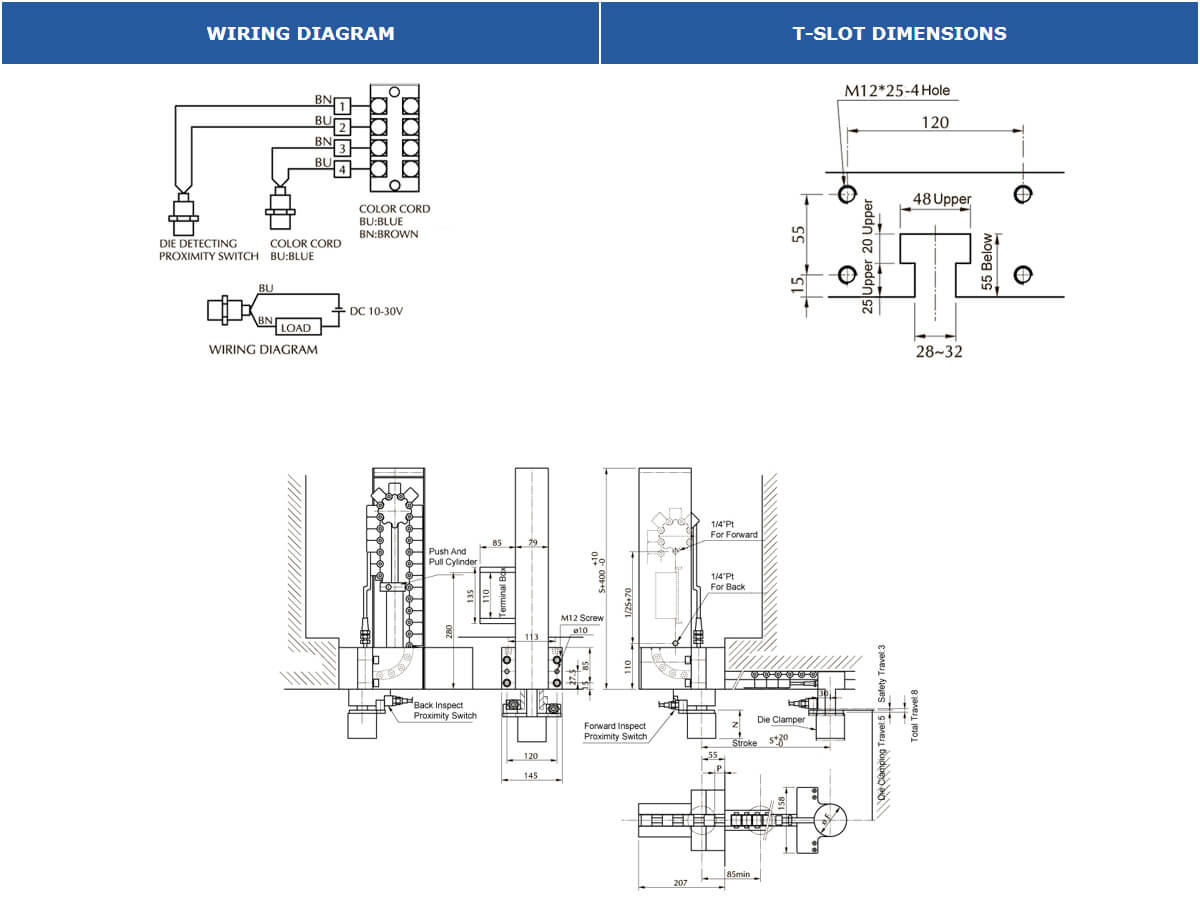

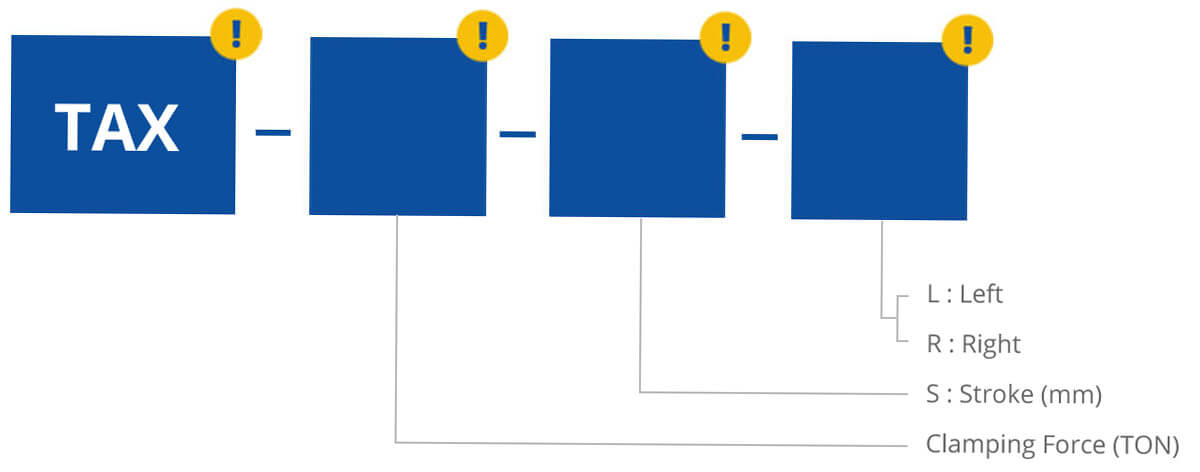

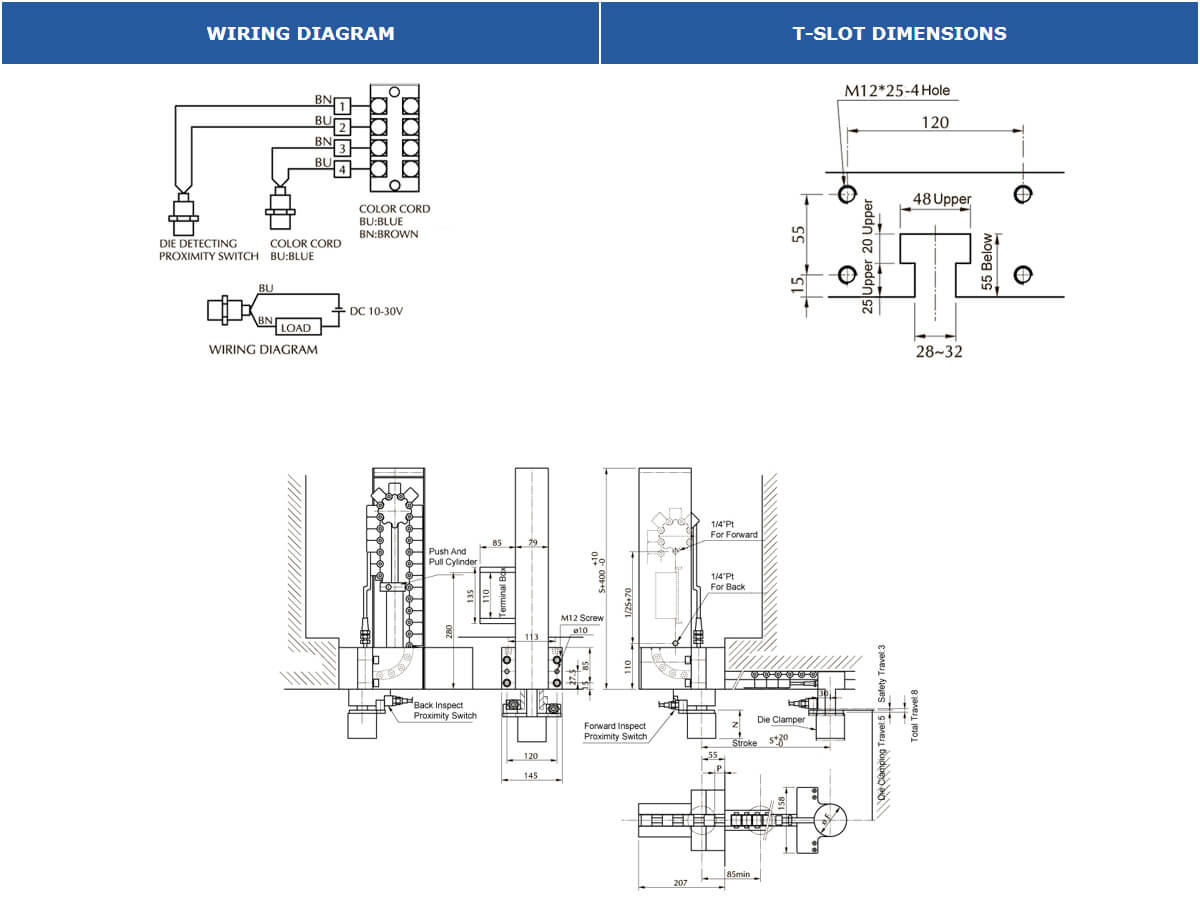

TAX Rotating Clamps

The TAX system uses an automatic pneumatic pressure mechanism to individually clamp upper dies. This system is well suited for both smaller and larger

hydraulic presses.

| Clamp |

F |

N |

P |

| TAX-4 |

68 |

68 |

24 |

| TAX-6 |

78 |

73 |

16 |

| TAX-10 |

98 |

79 |

6 |

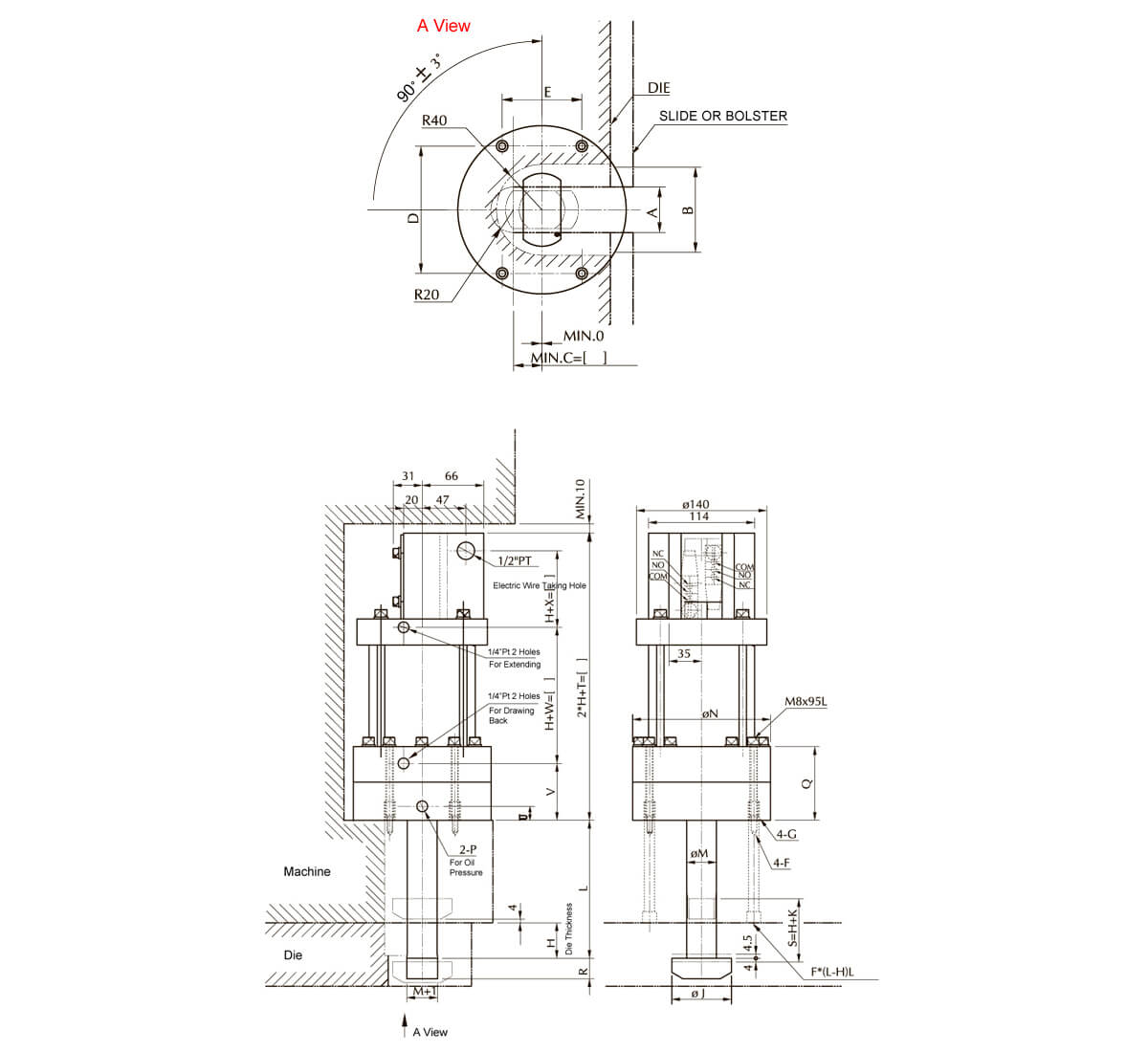

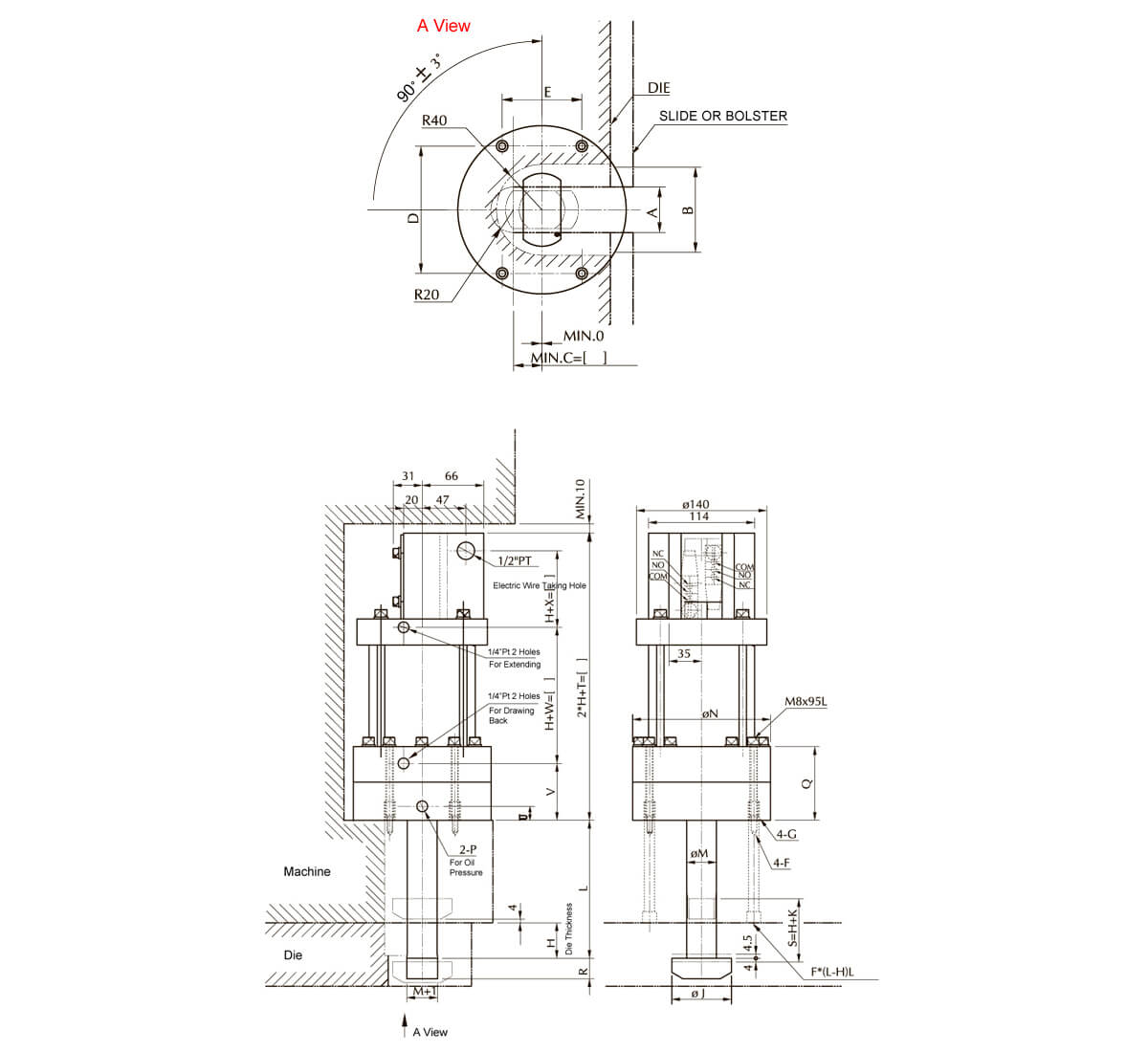

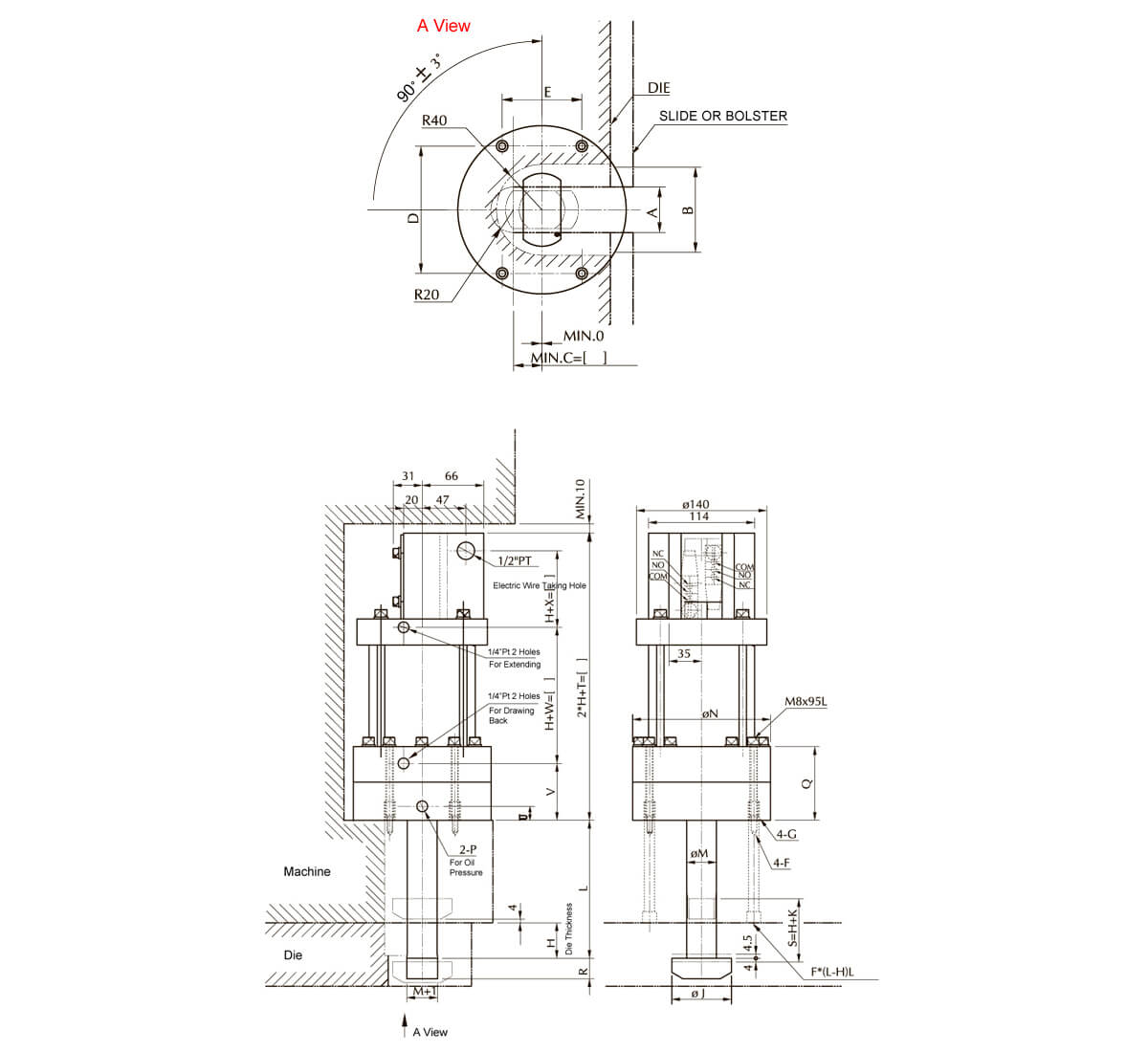

TR Rotating Clamps

The TR system uses a

hydraulic mechanism with a 90° turning movement to lock molds and dies into position. This heavy duty Clamping System is available in three different models with a clamping force up to 16 tons

| Proof Pressure |

27.0MPa(275kgf/cm2) |

| Max Working Pressure |

18.1MPa(185kgf/cm2) |

| Working Pneumatic Range |

0.4~0.7(4~7kgf/cm2) |

| Ambient Temperature Range |

-5~60°C |

| Hydraulic Fluid |

ISO VG32~VG56 |

| Model |

Clamping force(at 185kgf/cm2) |

Requited Qrantity(cc.) |

A±1 |

MIN.B |

MIN.C |

| TR-6 |

6 |

32.5 |

40 |

75 |

25 |

| TR-10 |

10 |

52.5 |

50 |

95 |

30 |

| TR-16 |

16 |

84.0 |

60 |

110 |

35 |

| Model |

D |

E |

F |

G |

J |

K |

M |

N |

PT |

Q |

R |

| TR-6 |

112 |

70 |

M8*16 Deep |

M12*20 Deep |

64 |

30 |

32 |

148 |

1/4 |

79 |

22 |

| TR-10 |

116 |

70 |

M14*30 Deep |

M14*30 Deep |

84 |

35 |

40 |

158 |

3/8 |

89 |

27 |

| TR-16 |

120 |

76 |

M14*35 Deep |

M14*35 Deep |

99 |

40 |

50 |

168 |

3/8 |

94 |

32 |

| Model |

T |

U |

V |

W |

X |

kg Maxx |

| TR-6 |

235 |

15 |

61 |

108 |

44 |

20 |

| TR-10 |

252 |

16 |

74 |

110 |

49 |

25 |

| TR-16 |

267 |

16 |

79 |

115 |

54 |

27 |

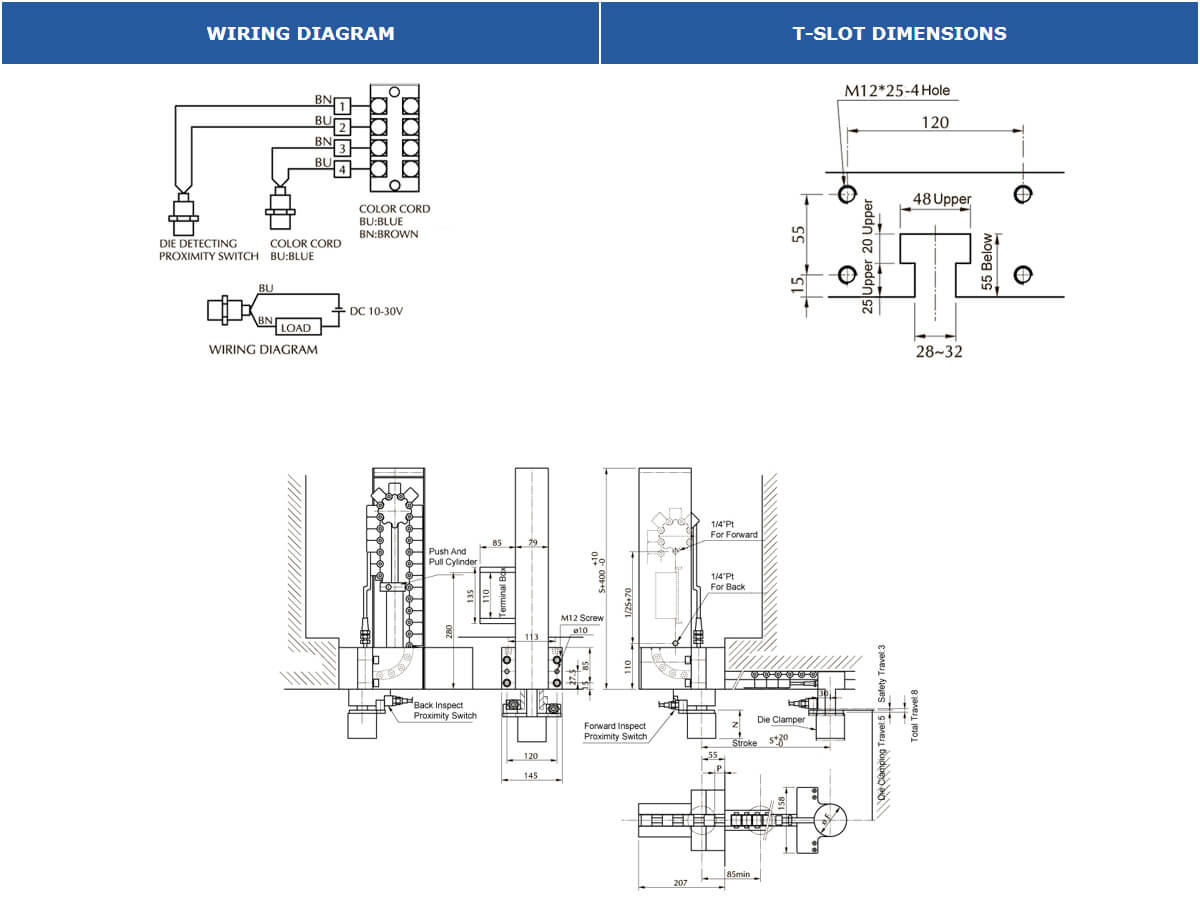

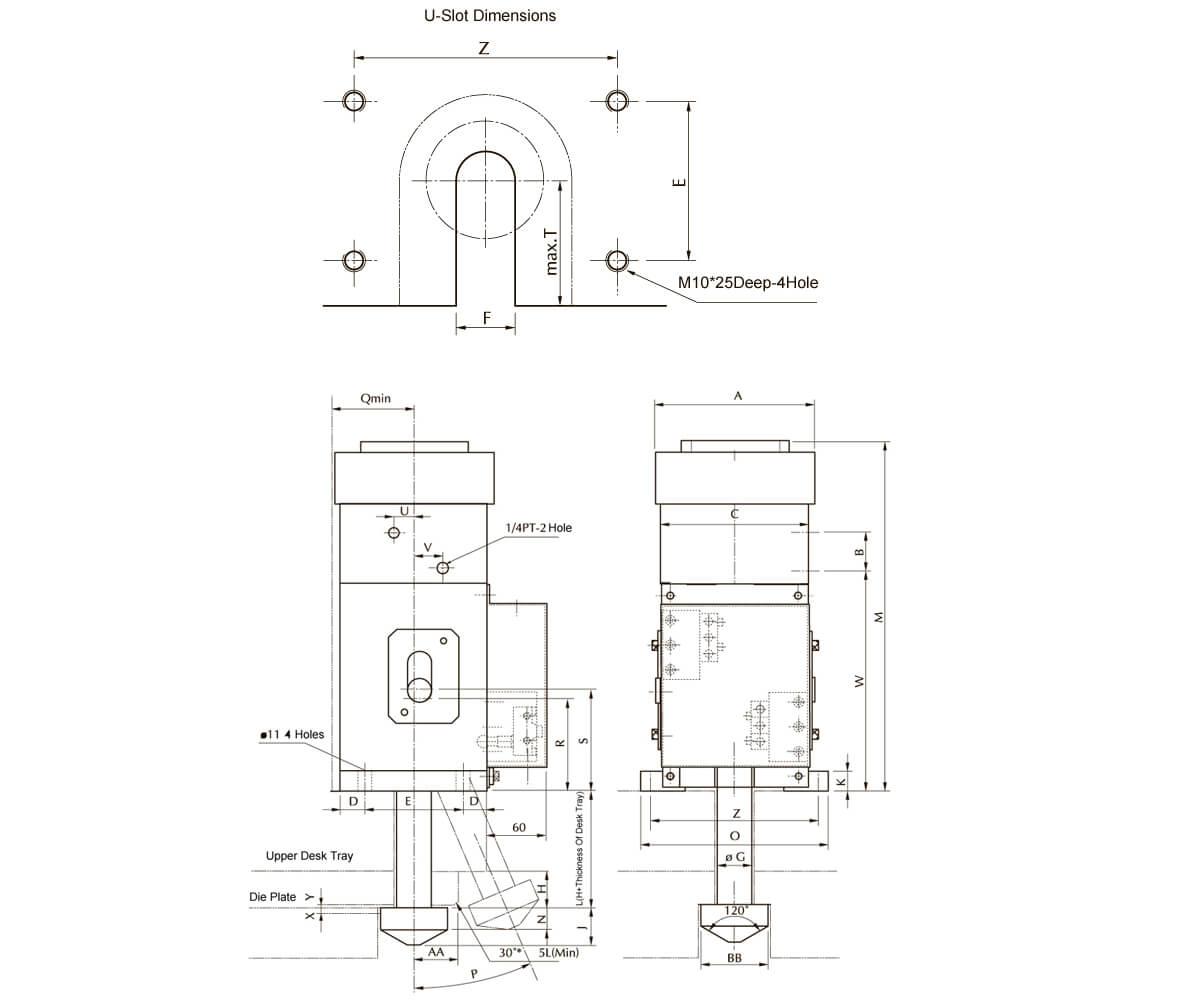

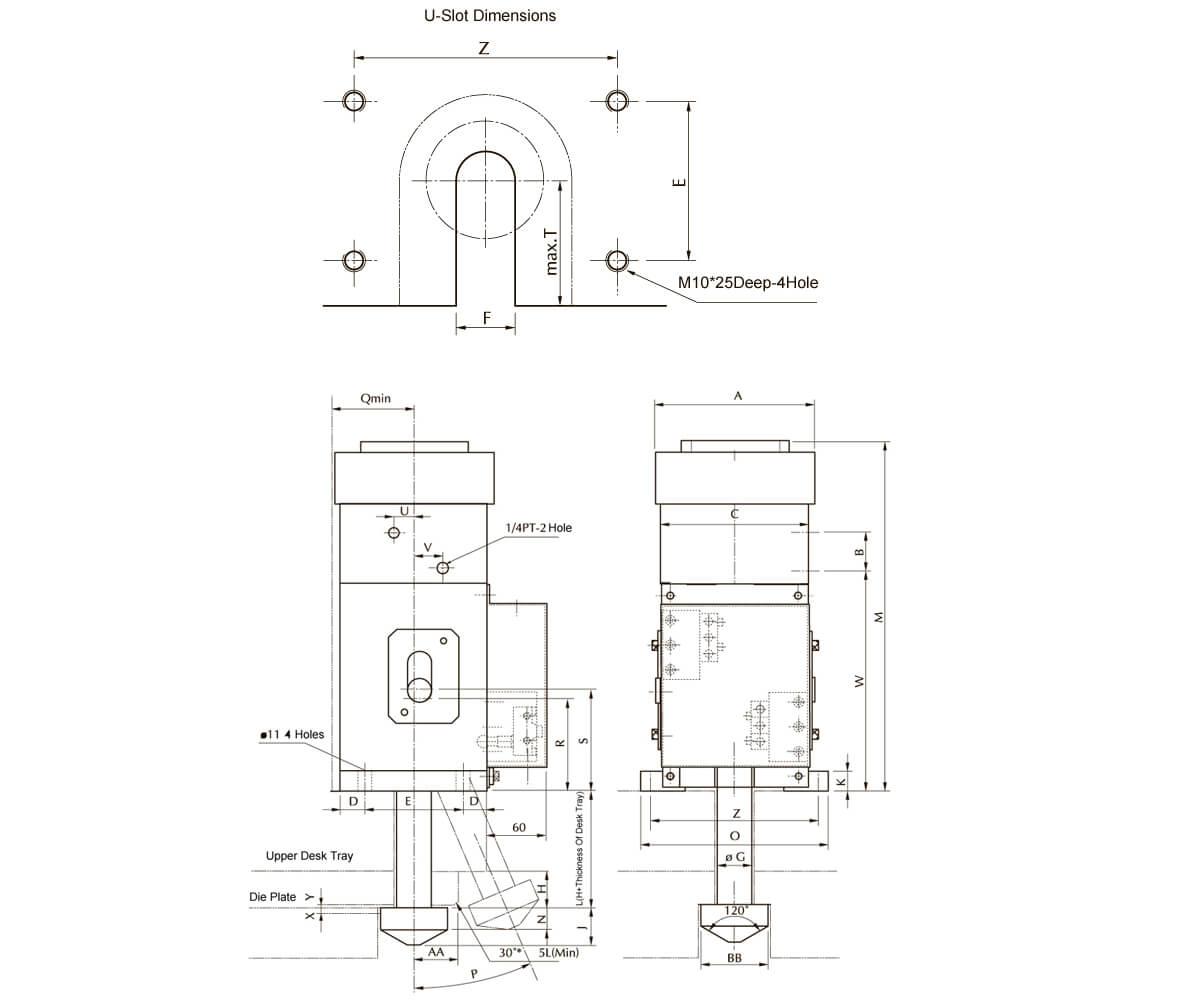

TS Swing Type Clamps

The hydraulic drive causes the clamp to swing open and replace the mold, and then it is swung in to clamp the mold.

| Proof Pressure |

275kgf/cm2 |

| Max Working Pressure |

185kgf/cm2 |

| Ambient Temperature Range |

-5~60°C |

| Hydraulic Fluid |

ISO VG32~VG5656 |

| Limit switch model |

Z-15G-Q-22B |

| Contact form |

Single pole double duty |

| Voltage |

AC125V, 20A

DC 30V, 6A6A |

| Model |

A |

B |

C |

D |

E |

F |

G |

BB |

Z |

J |

K |

M |

| TS-4 |

94 |

27.5 |

95 |

22.5 |

50 |

28 |

28 |

52 |

115 |

28 |

16 |

230 |

| TS-10 |

129 |

34.5 |

110 |

25 |

60 |

36 |

30 |

60 |

129 |

32 |

20 |

280 |

| TS-16 |

168 |

35.5 |

150 |

25 |

100 |

44 |

35 |

68 |

168 |

38 |

20 |

348 |

| Model |

N |

O |

P |

Q |

R |

S |

T |

U |

V |

W |

X |

Y |

| TS-6 |

16 |

135 |

24° |

55 |

55 |

60.5 |

55 |

15.5 |

19.5 |

143.5 |

5 |

2.5 |

| TS-10 |

20 |

150 |

21° |

70 |

68 |

75 |

70 |

11 |

19 |

178 |

5 |

2.5 |

| TS-16 |

20 |

190 |

36° |

85 |

93 |

102.5 |

85 |

21 |

19 |

226 |

6 |

3 |