تصنيف: التميز تايوان

بلد: تايوان

هاتف: +886-6-5950688 (6879)

فاكس: +886-6-5951129

الشخص الذي يمكن الاتصال به: Hank Wu, Manager +886-6-5950688 (6879)

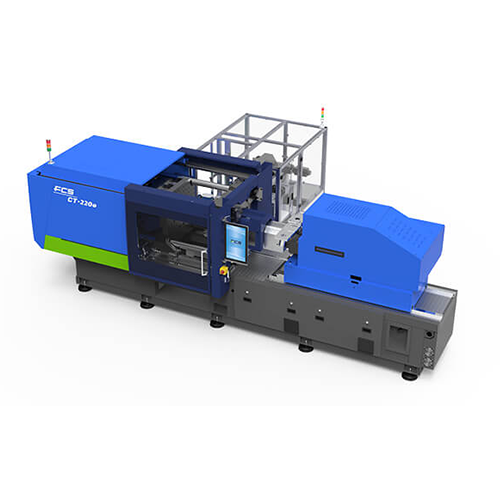

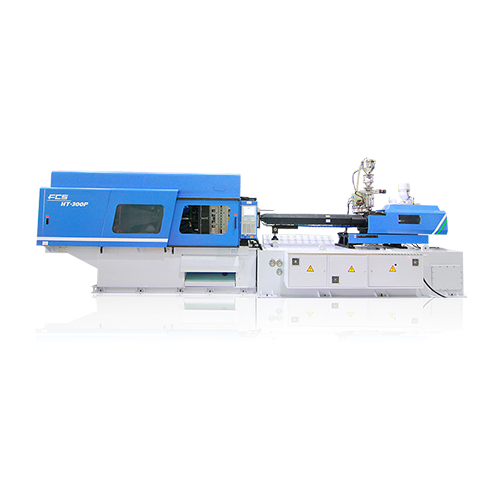

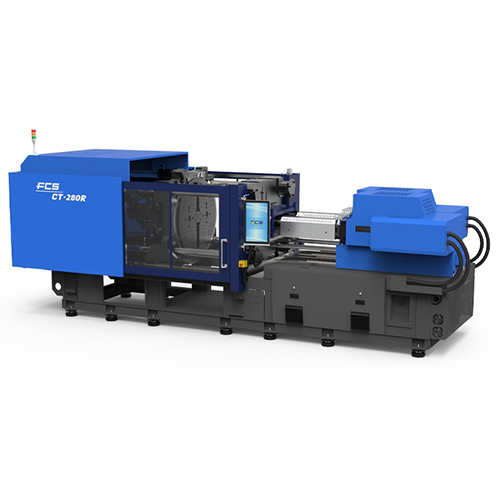

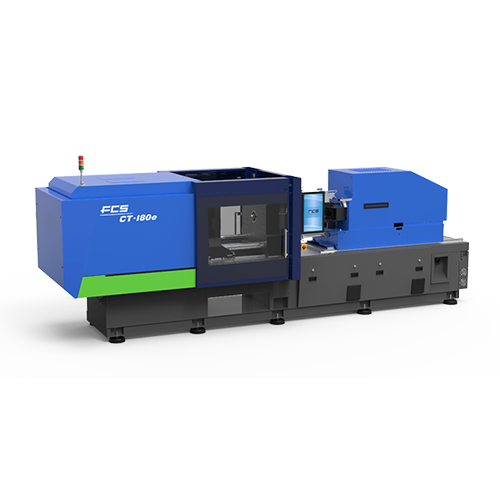

It is a newly released model of advanced toggle hydraulic and servo energy-saving IMM by FCS. The applicable industries include houseware, stationary, automotive, 3C and home appliance industries, especially for multi function printers, laptop or computer parts.

- Linear guide for injection carriage could lower the wear and tear, and make the injection control precise and stable.

- Servo injection closed-loop system could accurately control the speed of each shot, the injection time stability is >99.9%, and with stable molding product weight.

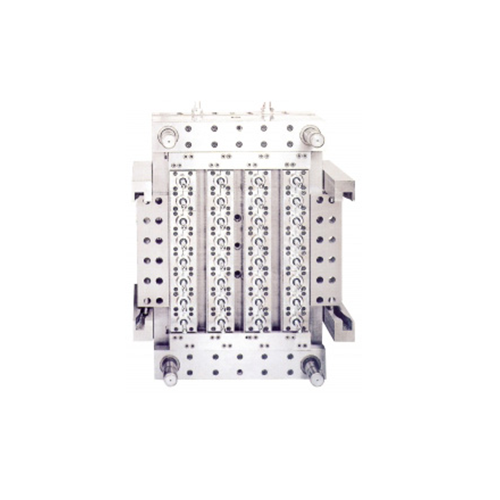

- The integrated and optimized hydraulic manifold and cylinder, improve the injection response, and expand the product application range.

- High mixing performance screw that improve L/D ratio and meet high injection volume products (and add D-screw choice for models above 250 ton)(optional).

- Optional modular specification, offering the high-speed type for option, to flexibly meet the requirement such as food packaging and thin-walled container industries.

- Adopted electric motor with brake which could offer stable adjusting control and position.

- Platen strength improvement that increase rigidity by 30%, lower deformation of mold plate, and improve the mold lifetime.

- Smooth the mold closing speed curve design, and add the S curve speed command to reduce the machine vibration.