Bio Resin Bag Making Line - JIT Series | JANDI’S

JANDI'S INDUSTRIAL CO., LTD. is committed to developing blown film machines combined with bag making, printing, and recycling machines. Until 2018, they obtained more than 30 patents of plastic machinery in China and Taiwan. With the concept of plastic reduction raising, JANDI'S proposes an idea about green innovation. The company develops JIT series integrated plastic bag making machines that are 100% suitable with biodegradable and compost materials such as PBAT and PLA. Moreover, JANDI'S added the automatic packaging part to JIT series.

Rotary Table Injection Molding Machine | TAIWAN KINKI

MACHINERY IN THE VIDEO: Rotary Table Injection Molding Machine with Full Auto System from TAIWAN KINKI (TKC) [TAIWAN KINKI LINES OF BUSINESS] Production of vertical plastic injection molding machines. Design of automatic injection molding machinery. Turn-key plants for accessories and peripherals for injection machinery. Injection mold design and manufacturing. Electrodeposition, powder coating, baking enamel, and leather treatment. Agency of the vertical injection machine and Zinc alloy coating. [APPLICATIONS] Especially suitable to manufacture Automobile Parts [TAIWAN KINKI (TKC) BACKGROUND] TKC had over 40 years of experience in Vertical Injection Molding Machine manufacturing. The company offers a full series of vertical injection molding machine portfolios including Standard, Slide, and Rotary table models. TKC also offers mold design and a full auto system for customer's products.

PRM Buyer Guide | PRM-TAIWAN

We have over 200 of the biggest and many of the small and medium-sized Taiwanese machinery manufacturers on our site and contacts with many more. Whether you are looking for full lines such as recycling machines extruders, blow molding machines, injection molding machines and printing machines, or auxiliary equipment and parts such as gearboxes, barrels, screws, molds, dies, control systems, and virtually anything related to the plastic and rubber industries including packaging. If it’s made in Taiwan, we will find it for you!

Central Drum (CI) Type Flexo Printing Machine | PRINTPLAS

The central impression drum surface precise grind and coated, without risk of pores and with the dual wall design for water cooling purpose to ensure material to be smoothly transport and precisely printed. 80mm thick cast metal plate frame provide a very steady, vibration free foundation for the printing work. Servo motors equipped for main drive / in-feed /out-feed / unwind and rewind, provide a smooth motion control for constant tension for film. Servo motors driven auto impression setting for each printing station with memory pack. Anilox sleeve and plate sleeve system is quick change side insert type. Turret type auto splicing for unwind and rewind is non-stop to change the roll. Equipped with internet accessible control system for remote diagnoses of programming and electronic components. 【Company Introduction】 Printplas Machinery Co., Ltd have been established since 2001 and specialized on the manufacturing of CI & STACK flexographic printing machine in Taiwan. With skill workers and machine R&D department, we are keeping our effort for providing precise, stable, high speed printing machine for our users.

2024 CHINAPLAS Interview | ARBURG

I'm honor to meet Dr. Christoph Schumacher, the vice president Global Marketing from Arburg. Let's hear about what's his thoughts on Chinaplas! And their new type machine launched in China.

2024 NPE Interview | NPE The Plastics Show

We at NPE invited PLASTICS Marketing Director Damaris to be interviewed by us. Sharing the latest news at the 2024NPE exhibition, there were 50,000 visitors on the third day of the exhibition. This is something very happy about.

Precision Mold Making & Injection Molding Solutions

Jia Thai Industrial Co., Ltd. Company Profile

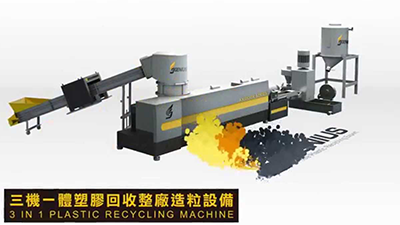

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS

Waste Plastic Recycling Machine - 3in1 Die-face Pelletizing Plant | GENIUS Specializes in waste plastic recycling machine, GENIUS MACHINERY CO., LTD. was established in 1992, professional in waste plastic recycling machine production line equipment design and planning. It also has the best credential and experience in shredder machine, waste cleaning line, film recycling machine. We are not only selling our waste plastic recycling machine products in Taiwan, but also we export our product to China, Indonesia, Philippines, and Saudi-Arabia, in order to promote the excellent technology, reputation and quality which are exclusive features of Taiwan to the whole world. Product Feature: -Drive-train: High torque gearbox made with precision grinding. Low noise, steady and smooth operation. -Low power consumption, high output. Dedicated screw and barrel design: According to the characteristics of recycle materials, dedicated screw is designed to completely impurities such as water and bad air; the screw also has a variety of advantages, for examples, good mixing, good dispersion, high output, and others. Die head pelletizing eliminates the labor cost on batter brace. No water tank. Consumes less space. Extruder is equipped with pressure sensors. When there is excessive pressure, warning light or buzzer send notification for replacing filter screen. No need to shut down the machine when replacing the filter screen. Single extruder suitable for cleaner material pellets such as injection leftovers, edge trim.

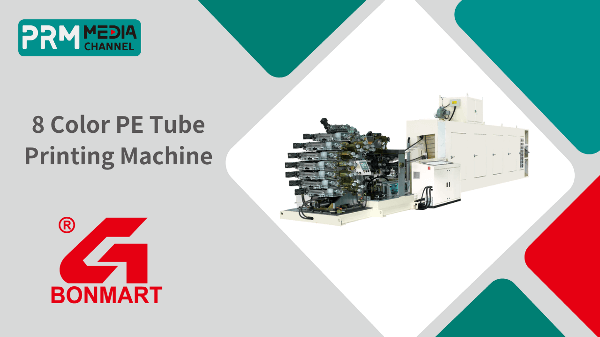

6 Cavities Automatic Injection Heading Machine | BONMART-

Double transferring rollers design. Stopless roller adjustment design. Plate wheel outer finetune mechanism Quick release ink rollers. Printing wheel clean system (200 mm dischargeable) Sleeve Printing Plate wheel pre-register mechanisim.

High Speed T Shirt Bag Making Machine|PLAS ALLIANCE

T Shirt Bag Bag On Roll with core auto insert system - 32RTWDFA-VR-2 Plas Alliance has a variety of plastic bag on roll machines for customers to choose, and is committed to innovation and research and development. So far, it has developed a variety of bag making machines for various bag formats. 【T-Shirt Bag On Roll Making Machine Features】 High speed Continue feeding system available in 200/250/300rpm systems. Tension-less sealing avoids sealing line pull & elongation for high-speed production. Rotary Die cut by Magnetic cylinder with simple die cut blade exchange. Inverter controlled feeding matching main machine speed for easy operation without manual adjustment. Support to work for Jumbo film slitting into two separate roll with post gusset in line system by Option (or model : 36RTWDFA-VR+SLG2) Equipped with LCD touch panel, easy to operate Switch control to exchange bag making process without adjustment Bag re-wind in roll , paper CORE insert in line automatic End of Film, core auto STOP 【Machine Available System】 Tension-less sealing T shirt bag on roll Flat bag on roll S type bag on roll 【Company Intro】 “PAL- Working with you to create all types of bag making automation solutions!” Like the first companies in 1988 to create the first bottom seal bag machine started, and since then, we have been studying bag machine design, manufacturing, innovation and change with the bag, we have always kept up to date technology, continue to explore, develop more labor-saving, cost-saving bag machinery, to provide customers with a complete bag packaging solutions, growing up with customers, a business partner to create the pinnacle!

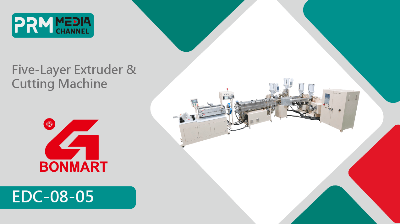

Five-Layer Extruder & Cutting Machine | BONMART

【Machine Features】 Plastic material has its own characters. In co-extrusion system. BONMART uses and combines several kinds of materials, therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube. Glossy surface (using: EVOH / RESIN / PE)Extensive color combination (using: PE + PEARL / PE + PIGMENT)Excellent barrier property (using: PE / TIE RESIN / EVOH / TIE RESIN / PE) Scratch and dust free (using: LDPE / LDPE / LLDPE)Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc. 【Company Intro】 BONMART offers complete-line including technology transfer, cost analysis, layout, installation, test run, training and satisfactory after sale services. Using our Squeezable PE Tube equipment is the best choice of good investment, Welcome to contact us for more details any time.

Plastic Inflation Machine | KANG CHYAU

Plastic Inflation Machine - Twin Head HDPE Plastic Inflation Machine-Kang Chyau Specializes in Plastic Inflation Machine. Since its founding in 1988 Kang Chyau Industry has worked constantly to bring out new and innovative Plastic Inflation Machine products and offer customers a wide range of choices. After more than a decade of work our products are now sold in 62 countries around the globe, a true measure of our success in the Plastic Inflation Machine market.

KAIMEI | PE Extruding Blow Molding Machine for Product Maximum to 1,500L - PBI-1305X-

Kai Mei Plastic Machinery Co., Ltd. established in 1977, is a highly reputed manufacturer of blow molding machines. Different types of machines are designed to produce containers of various raw materials such as PE, PVC, PP, PETG, PU, etc. Kai Mei can produce 5-ml containers of PBA Series Machines to 1,500-liter containers of PBI-X Series Machines. These are fully recognized by customers around the world.

Exploring the Future of Plastics Industry with Juan Eduardo Zarate | 2025 PLASTIMAGEN Interview

What’s next for the plastics industry? At 2025 PLASTIMAGEN, PRM-Taiwan interviews Juan Eduardo Zarate to uncover key insights into this year’s exhibition! Interview Highlights: How big is PLASTIMAGEN 2025? Discover the scale and number of exhibitors at this leading plastics event. Celebrating 25 Years: Special activities marking the 25th anniversary of PLASTIMAGEN! ESG & Sustainability: Plastics remain essential—how can we improve recycling and promote sustainability? ???? Subscribe to PRM-Taiwan for exclusive industry insights!

Saudi PPPP Through Familiar Eyes: Cosmo’s Perspective on an Evolving Show

Where is Saudi PPPP headed? In this on-site interview, Cosmo shares insights from years of participation, noting subtle shifts—like fewer machines on display. More significantly, Messe Düsseldorf’s quiet partnership hints at deeper changes in the region’s manufacturing and exhibition landscape

PRM Packaging Theme Pavilion | PRM What to Say EP7

Are you still seeking appropriate suppliers under the unstable circumstance of COVID-19? We heard your concerns and heartfelt wishes for attending an online exhibition! Through PRM Theme Pavilion, without traveling abroad, you will have many opportunities to connect with the world. Now, we are excited to announce an upcoming new event “PRM Theme Pavilion”, which will bring you to the new horizon. In this video, we are gonna present what you will see in this online exhibition. This time, we will focus on showcasing manufacturers who are specializing in the packaging industry.

sleeve seaming machine | WEBCONTROL

sleeve seaming machine -K1-SEAM200-Webcontrol - shrink sleeve seamer Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

WEI MENG | WMD Onion Bag Making Machine

Our Double Needle Bar Raschel Machine is the perfect solution for businesses that need to produce high-quality, high-speed packing sacks. With a working width of 170 inches and gauges of 2 - 6 needles per inch, this machine can produce a variety of nets for different purposes. It is also ideal for producing onion bag machines, special wide nets, and double-layered nets. This machine is equipped with a high-speed warp supply system that ensures that your nets are produced quickly and efficiently. It also has a number of features that make it easy to use, including a user-friendly control panel and an automatic yarn tensioning system. If you are looking for a high-quality, high-speed Double Needle Bar Raschel Machine, then our machine is the perfect choice for you. Contact us today to learn more about our machines and how they can help your business. Double Needle Bar Raschel Machine is specially designed for onion bag and double layer nets making. This machine is applicable Yarn is HDPE flat yarn and monofilaments. Standard gauges machine 2 - 6 needle per inch, Maximum performance of the machine can up to 600rpm.

Plastic Recycling & Pelletizing Machine | GEORDING

【Product Line】 Plastic recycling machine Compounding machine Dyeing & Pelletizing Automatic batch weighing and mixing system Washing line Rubbing drying machine Powerful crusher Shredder Plastic flat board extruder Refuse derived fuel (RDF) 【Company Intro】 GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well.

MOLD TEMPERATURE CONTROLLER, YANN BANG

YANN BANG, Patented Mold Temperature Controller, Temperature Controlled Unit Our temperature control unit can use water/oil heating system to secure the high quality of plastic production made by injection, extrusion and blow molding machines. Learn more: https://www.yannbang.com/mold-tempera...

Haitian Mexico Interview Part 2 | Solutions for Pandemic and Future Outlook

At the beginning of the month, we had a video conference with one of the greatest Injection Molding Machine Industry from Mexico, Haitian Mexico! In Part 2 of the video conference the Deputy General Manager of HAITIAN MEXICO, Jose Antonio Barroso, talked about the challenges they are having due to the pandemic, their solutions to overcome those challenges, and the current situation of COVID-19 in Mexico.

High Speed Side Sealing Machine with Wicketer | LIAN YOU

High Speed Side Sealing Machine with Wicketer

Blow Moulding Machine |FONG KEE

Blow Moulding Machine - High Speed Blow Moulding Machine-hba-ddgv-Fong Kee Specializes in Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

Plastic Wood Composite Profile Extruding Machine | CHEN YU

Plastic Wood Composite Profile Extruding Machine | CHEN YU CHEN YU PLASTIC MACHINE CO., LTD is a professional designer and manufacturer in Plastic Wood Composite Profile Extruding Machine.

Circular Loom Machine - 6 Shuttle Circular Looms | HAO YU

Introducing 6 Shuttle Circular Looms Machine from HAO YU. With HAO YU HY7-m6SCL six shuttles circular loom is designed with 6 shuttles to perform tubular weaving at high speed up to 180 RPM which is the highest technology in this woven bag equipment field in Asia. It reaches outputs up to 140 meters per hour. In case warp and weft breaks (finished), the machine stops automatically, An auto compensation system is also equipped to prevent the machine from empty weaving, it is an advanced circular loom specially designed to meet the stringent productivity requirements of today. The circular looms equipped with European inverter and high quality components. HAO YU is applying patent in Taiwan, China, India, and other countries. 【Machine Features】 Low spare part consumption & easy maintenance Energy saving nearly 50% over conventional models Large weft yarn insertion capacity up to 1080 PPM(max) Flat yarn applicable weaving denier from 500-1200(standard) Large weft yarn carriage capacity up to 115mm(max) Equipped with European inverter for main motor Lubrication-free for shuttle & cam 【Optional Accessories】 Gusseting device Both sides heat slitting device and additional fabric winder Center unfold device with heat slitting device and extra large unwinder for cement bag industry 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

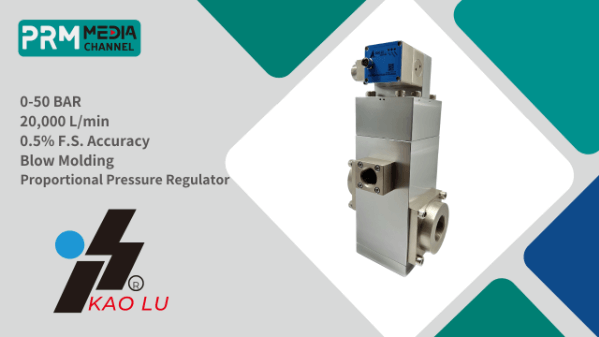

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd

Plastic Recycling and Blown Film Industry in LATAM | RRC Limitada (Polystar's Agent)

Recently, we had an interview with the General Manager and Auditor Accountant of RRC Limitada (Polystar's Chile Agent), a company based in Chile, which supplies South American countries with several kinds of plastics machinery including recycling machines, blown film extruders, bag making machines. They have vast experience knowing the machines and attending international exhibitions, which allow them to have a better understanding of how to assist a customer. RRC Limitada also represents Polystar Machinery, which is a successful Taiwanese manufacturer famous for recycling machinery and blown film extruders lines in many regional markets. Mr. Ricardo Rubilar and his son Rodrigo mentioned how their company's growth opportunities have increased in spite of the devastating impact pandemic has brought to the global economy. In the video, we will see how they explained the importance of having an agent in local markets can give a company greater selling results and enhanced services to local buyers.

Second Life to Recycled Plastics | BoReTech

Have you wondered how PET bottles have been recycled? Where do recycled plastics go? BoReTech is a leading company in the plastic recycling industry, who strives to solve plastic waste and give it a second life. With more than 30 years experience in the industry, BoReTech is able to process different materials from different countries and gain know-how experiences. Lately, BoReTech has redesigned their washing line in a smaller footprint, which is 50% less surface area compared to their standard line. Here are four improvements of the latest washing line called ES-process PET Bottle Recycling System. Smaller Foot Print Convenient in Maintenance Environmental Protection and Sustainability Quality Improvements To be a global pioneer in the plastic recycling ingenuity, BoReTech has gradually moved towards the research, development, and design of the all-plastic recycling process. Let's keep our environment in ecological balance and promote global sustainable development. 【Video Outline】 0:00 Reduction of Carbon Emissions 0:52 BoReTech's Plastic Recycling Solution 1:32 Journey to Plastic Recycling 3:11 Development of BoReTech 3:54 Innovation & Integration to meet food-grade demand 4:38 BoReTech PET Bottle Recycling System 5:10 ES-process PET Bottle Recycling System 7:07 Market share of BoReTech in India & Japan 8:51 Service from BoReTech 9:46 Future Development & Mission

Plastic Washing Machine | GEORDING

Plastic Washing Machine - Plastic Film Crushing Washing and 3IN1 Pelletizing Line - Waste Plastic Crushing & Washing Line 1000kg - GEOR-DING MACHINERY CO., LTD.. We specialize in manufacturing of Plastic Washing Machine. The main businesses include: Plastic Washing Machine and planning of entire plant’s equipment. While the demand for output and quality in Plastic Washing Machine worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Plastic Washing Machine products and services to higher standards.

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8

Escalation of Industry 4.0 in Plastic Machine Industry | PRM What to Say EP8 Nowadays, everything has been advanced to automation and connection to the Internet. Even in the Plastic and Rubber Industry, which we might consider as the traditional industry, it has been upgraded gradually through the industry 4.0 revolution. Let’s take a quick look to understand what are Industry 4.0 and IoT, and how does the Plastic and Rubber Industry apply it. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

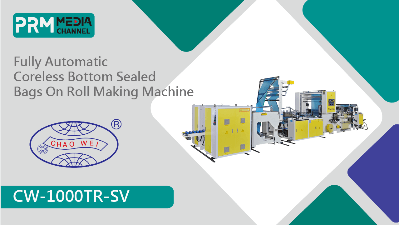

Fully Automatic Coreless Bottom Sealed Bags On Roll Making Machine | CHAO WEI

【Machine Spec & Features】 Bottom Sealed Bags On Roll Making Machine (Coreless) Film width: 600 mm / Thickness: 15 micron E.P.C Control & Rollers Device (E+L, German made) Length: 750 mm x Speed: 135 Pcs/Min Production Line Speed: 100M/Min Servo Driven Shuttle Type Sealing & Perforating Unit Two Sets Triangle Folders For Making Finished Roll With Small Width Machine Maintains High Speed Production By 4 Sets Rewinding Shafts While Producing Small Quantity Of Bags Per Roll 【Company Introduction】 Chao Wei Plastic Machinery is an advanced manufacturer of plastic bag making machine with more than 35 years of experience with ISO 9001 & CE certificates in Taiwan. One of the reasons for the excellence of Chao Wei’s machines is our dedication to research and development.

Turkish Plastic Market Evaluation | PDA GLOBAL Interview (POLYSTAR Agent)

PRM Media Channel continues to share with you the most current industry insight into local markets around the world. This time our guest of PRM Industry Insight program is Mr. Emrah Cakir from PDA GLOBAL company, as well as the agent of POLYSTAR in Turkey. We have touched on many current topics of the plastics machinery industry including the shipping obstacles, current plastic packaging machinery demand of the Turkish market due to emerging needs, advantages of having a local agent in the Turkish market, the fluctuation in the foreign currency in the Turkish market, and so on. Let's take a look at the video and hear more from Mr. Cakir about his solution suggestions to the current issues in the market. Know PRM Media Channel more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan

Twin Head Blown Film Machine for Plastic Bag Manufacturers | POLYSTAR

Introducing POLYSTAR Twin Head Blown Film Machine with the motto of the company: "Extrusion Made Simple". The blown film extruder is specially designed for HDPE and LDPE bag producers. 【HIGHLIGTS OF Twin Head Blown Film Machine】 - Monolayer (1 Layer) - Two Die Heads, Single Screw - Film Width from 150~650mm - Extruder Dia: 45mm, 55mm, 75mm - Material: HDPE, LDPE - Output: 30~140 kg/hr - Works with virgin, recycled materials, Biomaterials, and CaCO3 - Possible end products: T-shirt bags, Bottom sealed flat bags, Shopping bags, Supermarket bags, Garbage bags 【MACHINE PORTFOLIO OF POLYSTAR】 1. BLOWN FILM MACHINES - One Layer Twin Head HDPE LDPE 650mm Machine - Multilayer Blown Film Machines - One Layer HDPE / LDPE 800mm (Mini type) Machine - AB - 2 Layer Co-Extrusion LDPE/LLDPE Machine - One Layer HDPE LDPE LLDPE 1500mm Machine 2. BAG MAKING MACHINES - Bottom Sealing Bag Making Machines - Folded Garbage Bags Machines - Perforated Bag on Roll Machines - Thick Bag Making Machines - Laundry Bags Machines 3. RECYCLING MACHINES - Plastic Recycling Machines - Plastic film recycling Machines - Two stage recycling Machines - Air cooled recycling Machines - Hopper feeding recycling Machines - Shredder integrated recycling Machines 【ABOUT POLYSTAR】 POLYSTAR is a pioneer manufacturer of Plastic Recycling Machines, Blown Film Extruders, and Plastic Bag Making Machines. The company has gained the trust of its customers with 32 years of experience in the industry, today POLYSTAR has been sold over 4,000 machines in 105 countries worldwide.

All electric blow moulding 20L jerrycan energy saving, no hydraulic oil, no pollution, industry 4.0 | FONG KEE

Model No : FK/EHB-55G-100G-55GT20SD Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system.

Flat Yarn Extrusion Line & Raffia Tape Stretching Line | HAO YU

HAO YU Raffia Tape Stretching Line is designed for producing PP/HDPE raffia tape and flat yarn. 【Equipment Features】 - Capacity: 160 ~ 520 kg/h - Designed for making 500-1500 denier - Working speed 100-270 meter/minute - A screen filter changer - Rotary blade slitting system - Synchronized control electronic system - Low energy consumption - Less downtime - Reduce production loss 【Additional Features】 - European-made gearbox - T-die - Melt pump - Tape winder - Designed for making 2000-6000 denier upon special request 【Finished Products】 - Woven bag - Geotextile - Artificial grass - Carpet backing production 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

Bottle Grade PET Bottle Washing Line | BoReTech

MACHINERY LINE IN THE VIDEO: Bottle-to-Bottle Grade PET Bottle Washing Line from BoReTech. The line is mainly used for PET bottle-to-bottle projects (FDA Approval), which recycles post-consumer PET bottles into rPET flakes. The regenerative PET flakes conform to the quality index requirements of downstream food packaging and are used for bottle blowing and packaging which can directly contact food after pelletizing and SSP processes in the late stage. HIGHLIGHTS Solutions for diversification of input PET bottle bales. Automatic de-baling technology, reduces labor, a strong bale breaking ability for high-density PET bottle bales. Patent technology for PVC label removal. Patented Pre-washing and hot washing process to ensure the cleanliness of rPET flakes. Integrated technology and capability for automatic sorting machine and PET bottle recycling line. The hot washing process reduces impurities content to achieve food-grade index. Stable and reliable quality of rPET flakes, online inspection to ensure the stability of rPET flakes. Completed online water recycling treatment system for pre-washing, hot-washing, and rinsing. Low operation breakdown, production management guidance service for the customers. FOOD GRADE PET BOTTLE RECYCLING PROCESS De-baling➜Metal Removal➜Label Removal➜Metal Removal➜Bottle Pre-washing➜Optical Bottle Sorting➜Manual Sorting➜Crushing➜Dust Removal➜FlotationHot washing➜Friction Washing➜Rinsing➜Flushing Washing➜Drying➜Dust Removal➜Optical Flakes Sorting➜Blending➜Online Inspection➜Packing FOLLOW PRM ON: PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ #BoReTech #PRMMediaChannel #PETrecycling #PETwashingLine #BottleToBottleRecycling #PRMTAIWAN #Plastics #Rubber #Industry #Internationalmarket #Export #machinery #PET #PETbottle #Recycling

2024 TaipeiPlas International Plastics & Rubber Industry Show| Geording

In this video from the 2024 TaipeiPlas International Plastics & Rubber Industry Show, we present Geording’s machine designed to support green policies. With a self-cleaning screen changer, their equipment helps customers enhance efficiency and focus on green recycling development. Geording has maintained a long-term working relationship with Polaris, and we explore their experience with our services. Watch to learn more about Geording's commitment to sustainability in the plastics and rubber industry!

Extrusion Blow Moulding Machine |FONG KEE

Extrusion Blow Moulding Machine - High Speed Blow Moulding Machine-hbb-ssg-Fong Kee Specializes in Extrusion Blow Moulding Machine, Fong Kee International Machinery Co., Ltd. (FKI) is the largest and finest Extrusion Blow Moulding Machine manufacturer in Taiwan Plastic Extrusion Industry. Established in 1953 by founder C.C Wei and spread its business to over 100 countries . FKI manufactures variety of Extrusion Blow Moulding Machine and etc. If you are looking for good Plastic Extrusion Machine Supplier, please feel free to contact us.

Proportional Pressure Regulator Valve | QKL-B2T+External Pressure Sensor | KAOLU

00:00 QKL-B2T Proportional Pressure Regulator Valve + External Feedback Pressure Sensor Product Introduction 00:21 QKL-B2T+External Feedback Pressure Sensor Description 00:29 Product Function: Boost Flow 00:40 Product Feature: Remotely controls cylinder pressure What is a Proportional Pressure Regulator Valve? In pneumatic world, a proportional pressure control valve is used to control downstream air pressure with an electronic signal. The input electronic signal is proportional to the span of the output pressure. For example, 0-10VDc of command signal corresponds to the output pressure span of 0 - 10 bar, with linear proportion relationship. Type of Proportional Pressure Regulator Valve? Kao Lu offers three types of electronic proportional pressure regulator: pressure ranges from vacuum -1~0bar, low pressure 0~2bar, 0~4bar, 0~8bar, medium pressure 0~16bar, 0~30bar, up to high pressure 0~70bar. In the high pressure control, the resolution can reach 0.5~0.6 bar. Proportional Pressure Regulator Valve Working Principle? Proportional Pressure Control Valve adopts a closed loop design and consists of two solenoid valves, an internal pressure sensor and an electronic control; according to an analog signal input, one solenoid valve is used to control the air intake and the other is used to control the pressure. Both valves work together to achieve a precise proportional pressure control. The proportional pressure regulator adopts two types of input signals: 0-10VDC or 4-20mA, and three types of monitor output signals: 1-5V, 0-10V or 4-20mA.

Quick Mold Change - Clamping System | FORWELL

Forwell has been a pioneer of Quick Mold Change Systems for many years. With over 20 years of experience in developing these systems they can offer you the best for your molding operations. These fully customizable Quick Mold Change Systems drastically minimize setup times, maximize efficiency and increase safety. Forwell’s Quick Mold Change System can be designed to fit almost any injection molding machine and mold casting machine to allow for quicker mold change times, resulting in shorter machine down time and increased productivity. This system uses a special mold clamp that does not require a cut out on the mold, increasing its application versatility and allowing it to be used with a large number of different molds.

Plastic Recycling in Japanese Market at K 2022 | POLYSTAR

We were glad to have an interview with Mr. Kenji Murai, agent of POLSTAR in Japan, who shared his observation of plastic recycling in the Japanese market and his experience doing machinery business.

Side Entrance Two Stages System | GEOR DING

Side Entrance Two Stages System - Side Entrance Two Stages Die-Face Cutting Recycling & Pelletizing Machine GEOR-DING MACHINERY CO., LTD.. - Manufacturer of Side Entrance Two Stages System and more. We specialize in manufacturing of Side Entrance Two Stages System. The main businesses include: Side Entrance Two Stages System and the planning of the entire plant’s equipment. While the demand for output and quality in Side Entrance Two Stages System worldwide is increasing day by day, our determination for upholding the motto, “Quality is number one. Output comes second. Customer satisfaction. Perfect service”, will never shift. Under your support and encouragement, we will continue to provide quality Side Entrance Two Stages System products and services to higher standards.

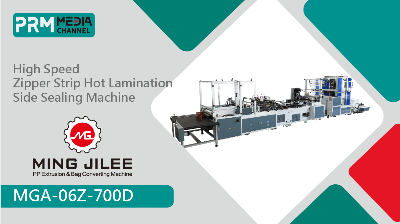

High Speed Zipper Strip Hot Lamination Side Sealing Machine | MING JILEE

【Machine Features】 Taiwan-made and stable PLC controller The size control of Zipper Bag Side Sealing Machine is by servo motor. Made in Japan. Zipper Bag Side Sealing Machine is equipped mark sensor for printed material. For getting the best quality of zipper bag product, unwinding station is mount the auto tension control. The individual zipper strip unwinder with motor control to get the high quality of zipper sealing quality. Ultrasonic welding is design by motor driven for highest speed production. The ultrasonic welding station to crack the zipper on the edge of the bag for easy side sealing cutting. 【Company Intro】 Ming Jilee Enterprise Co., Ltd. is manufacturing film blowing machinery with materials of PP and LD/HDPE; PP thin and thick sheet making machine; waste recycling and pelletizing machine, stationery making machinery- can produce business file/data bag/file clip/photo pocket/name card pocket/index/bubble paper envelope; sealing & cutting machinery-side sealing bag/t-shirt bag.

2023 Plastics & Rubber Indonesia On-site Tour | PRM-TAIWAN

Check our on-site tour video for Plastics & Rubber Indonesia 2023! Taiwanese suppliers, which is specialized in the Plastic & Rubber industry, known as its high quality machinery. If you don't want to miss out the latest news, stay tuned!

Isothane TPU Resin (Thermoplastic Polyurethane ) | GRECO

Isothane TPU Resin (Thermoplastic Polyurethane ) - Eco Solution to the Future | GRECO ISOTHANE TPU (Thermoplastic Polyurethane) resin series of GREAT EASTERN RESINS INDUSTRIAL (GRECO) are high quality environmentally friendly materials and available in a wide range of hardnesses in polyester and polyether-based formulations. ISOTHANE exhibit the valuable characteristics of flexible rubber and rigid plastics and their wide spectrum of mechanical properties meet customers’ demands in extensive applications. ISOTHANE TPU resins portfolio includes high transparency grades, hot melt grades, breathable film grades, anti-static grades, engineering-grade, low compression grades, bio-renewable, and flame retardant grades. For more information, please click the inquiry link and contact GRECO directly.

Application of Adhesive Technologies in Recycling Composite Material | PIIF

講者: Henkel 德商漢高台灣分公司 吳念先 大中華區高級顧問 《塑膠產業創新論壇》定位為 塑膠產業商務交流的平台 塑膠中心本於推動塑膠產業創新的理念,每年辦理一次《塑膠產業創新論壇》活動,透過推動塑膠產業創新,發揮影響力,滿足社會的需求,實踐造福人群的力量。 《塑膠產業創新論壇》每年挑選產業重要關鍵議題,透過主題論壇、研討會、技術展覽…等形式,引領產業最前瞻的趨勢與做法,期盼耕耘成為塑膠產業的年度盛會。 長期展望為透過本論壇匯聚產業夥伴關係成為塑膠產業創新的生態圈。

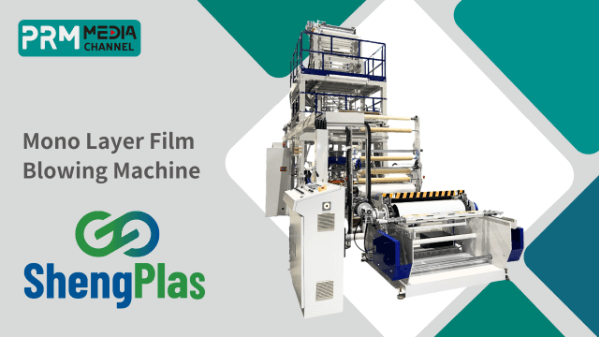

Mono Layer Film Blowing Machine | SHENGHONG

Mono Layer Film Blowing Machine