Film/Bags Waste Plastic Recycling Machine - KCR-85 | KANG CHYAU

Inquiry and More Info: https://bit.ly/3hVGAvO Introducing the Film/Bags Waste Plastic Recycling Machine from one of the pioneering plastic recycling machinery and film extruder manufacturers in Taiwan, KANG CHYAU. Please click the link above for more information and/or inquiry, which will direct you to the manufacturer. For any assistance, PRM will be more than happy to assist. Contact us through our social media platforms or leave a comment below. Then we will reply and contact you asap. Machinery in the video: Film/Bags Waste Plastic Recycling Machine Model No: KCR-85 Output:80-120 kgs/hr Screw Diameter: Ø 85mm Single Dega Sification Suitable Materials: HDPE/LDPE/LLDPE

PRM Media Channel at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. In 2020 many large exhibitions in the world have been forced to cancel/postpone due to the global pandemic. Thanks to Taiwan's relatively safer environment, TAIPEI PACK successfully launched as a combination of six different Exhibitions in one. There are more than 900 domestic and international exhibitors on-site waiting to meet the visitors. Moreover, there are many online on-site exhibitions and conferences scheduled for the interest of global visitors. During the exhibition, PRM Media Channel conducted interviews with the exhibitor to gather insights into the industry. Stay tuned for the forthcoming interview videos and remember to subscribe to PRM Media Channel!~

Flat Yarn Extrusion Line & Raffia Tape Stretching Line | HAO YU

HAO YU Raffia Tape Stretching Line is designed for producing PP/HDPE raffia tape and flat yarn. 【Equipment Features】 - Capacity: 160 ~ 520 kg/h - Designed for making 500-1500 denier - Working speed 100-270 meter/minute - A screen filter changer - Rotary blade slitting system - Synchronized control electronic system - Low energy consumption - Less downtime - Reduce production loss 【Additional Features】 - European-made gearbox - T-die - Melt pump - Tape winder - Designed for making 2000-6000 denier upon special request 【Finished Products】 - Woven bag - Geotextile - Artificial grass - Carpet backing production 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

Paper Bubble Mailer Making Machine, MGA 47P 1000 | MING JILEE

Paper Bubble Mailer Making Machine, MGA-47P-1000 Learn More:https://www.mingjilee.com/tw/product/... MING JILEE: PP Extrusion Line and Bag Converting Machine Since 1987 Made In Taiwan, Best Quality and Global Support Website: https://www.mingjilee.com/ E-mail: [email protected] Whatsapp: +886 934 081 955 Complete Address: No.76-8, Ming-Ho, Ming-Ho Vil., Shan-Shang Dist., Tainan City, 74342, Taiwan

Company Introduction | ALFA

Alfa Industrial soul thought - professional quality, put product quality in the first place. Whether it is the procurement of parts in the early stage or the final machine inspection, Alfa Industrial strictly monitors every link, every process and every detail to ensure the stability and performance of each machine. Email: [email protected]

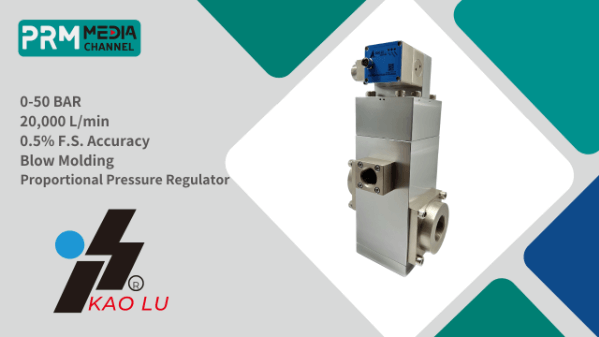

Ultra-Series QKL-HS1·HS2 Electronic Air Pressure Regulator | KaoLu

Product Description The low flow electronic pressure regulator (electric air pressure regulator) is suitable for industries that require precise pressure changes at any time and monitor pressure values. Moreover, the electronically controlled pressure regulator price of B3-1A is economical to this extent that the user can afford it with no hassle. Similar goes for electronic gas regulators; it's a digital air regulator that possesses the ability to resist massive quality air pressure. Over and above, the electronic pressure regulator (electronic proportional air regulator) Arduino is an open-source electronics platform that is especially designed to make electronic machinery more accessible in this digital era. The digital air pressure regulator facilitates the users with the digital reading of the present output pressure value. Another useful feature is an air flow regulator with digital pressure gauge that allows users to measure the quantity of the pressure allotted to the mechanical device for its operation. Available with 3 selections of input signal: 0-10VDc, 4-20mA, or RS485 Modbus. Monitor signals can be chosen from 1-5V, 0-10V, or 4-20mA. Our special design offers high pressure and high flow capability electronic air pressure regulators in unibody design. For applications that require a high pneumatic flow rate, we offer the option of an air pilot volume booster to amplify downstream flow. For applications that require an external pressure transducer, there is also an option to link our pressure regulators to external sensors for closed-loop control. All our electronic pneumatic regulator have CE, SGS, RoHS certification with ISO13485 quality system. Applications: Laser cutting, leak tester, tension control, PET bottle molding machine, multi-stage pressure control, etc. Applications for Electronic Pressure Regulators Spraying/ Painting Air Blowing Leak Testing Filling Pressure Artificial Heart Laser Cutting FAQ session – Proportional Electronic/Digital Pressure Regulators What are the differences between Proportional Pressure Regulator, Electronic Pressure Regulator, Electro Pneumatic Pressure Regulator Electronic, I/P Converter, Digital Pressure Regulator, and air flow regulator with digital pressure gauge? They are the same products with different names. Where is the digital pressure regulators used? Digital pressure regulator is usually used for laser cutting, plastic blow molding machines, tension control equipment, tire making machines, etc. Is the pressure regulator resistant to dirt? No, it is not resistant to dirt particles. Please use dry clean air and filter with < 5 μm. Any restriction on mounting orientation? Electronically controlled pressure regulator Arduino is especially designed to operate mechanics. There is no restriction on mounting orientation; however, please be aware to protect the regulator from environmental water drop, oil, and welding slag. Knowledge Base How Does a Proportional Pressure Regulator Work? A Proportional Pressure Regulator has many advantages over mechanical manual regulators. A manual regulator will maintain pressure downstream, most effectively with constant upstream flow rates. However, upstream flow and pressure will often fluctuate in most applications. Pumps and compressors deliver pulses, and the pressure will fluctuate with demand. When a mechanical pressure regulator lacks accuracy or can’t respond fast enough, the result is uneven pressure output. This simple device might be good enough when accuracy isn’t as crucial. However, a digital pressure regulator delivers better accuracy and stable output pressure by utilizing a control signal and the feedback signal to create closed-loop pressure control. Uses of Regulators Electronic pressure regulators (electric air regulators) maintain a constant output pressure within a pressurized system even if there are fluctuations in the incoming pressure to the regulator. Mechanical pressure regulators are typically only adjustable by hand, limiting their usability in a digitalized process environment. When using an electronic gas pressure regulator with a digital control system, the precise output pressure is controllable via slight adjustments to the control signal. An internal pressure transducer creates a closed loop control device and offers a feedback voltage of the current output pressure. By reading this feedback signal from an electronic regulator, control systems can make real-time adjustments, greatly improving consistent pressure regulation in the most demanding applications. The Working Process: Electronic pressure regulators (automatic air pressure regulator) are a big improvement over manual regulators; they are simple and very effective at allowing better control. An electronic air regulator uses a fill valve and a vent valve to maintain the outlet pressure at the desired set-point. A small inner pressure sensor monitors the output pressure and the digital controller adjusts the flow output of the internal valves to retain the required set-point (i.e. closed-loop control). That means that when you set the desired pressure, the regulator(pressure regulator digital) will maintain this pressure even with changing flow rates through the system. The internal pressure transducer gives immediate feedback to adjust the flow of either the fill or vent valve so the output pressure remains static. When the control signal increases, the internal proportional pressure control valve activates, increasing pressure into an internal pilot chamber. When this happens, more of the inlet pressure passes through the proportional fill valve and into the pilot chamber. The pressure in the pilot chamber grows and causes the upper surface of the diaphragm to operate. Because of this, the air supply valve linked to the diaphragm opens, and a portion of the supply pressure becomes output pressure. This output pressure goes back to the control circuit using the pressure sensor. The fill valve will continue to slightly adjust until the output pressure is equivalent to the desired set-point of the control signal. Please check our video on: GennDih Enterprise. Co. Ltd

Plastic Wood Composite Profile Extruding Machine | CHEN YU

Plastic Wood Composite Profile Extruding Machine | CHEN YU CHEN YU PLASTIC MACHINE CO., LTD is a professional designer and manufacturer in Plastic Wood Composite Profile Extruding Machine.

Seaming Machine | WEBCONTROL

Seaming Machine-300(K2)-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

Crystallized Hopper Dryer(PET Crystallizer) - Engliish Subtitle | Yann Bang

The crystallized hopper dryer is designed with a unique mixer inside the stainless insulated hopper.The unique mixer stirs the resin simultaneously while the unit is drying.To crystallize,it increases the I.V. value and speeds up the crystallization. To Dry the mixer dries evenly and shortens the drying time.

CHINAPLAS On-site Tour Hall No.7 | PRM-TAIWAN

What! You don't know which manufacturers are participating CHINAPLAS? Hurry up and check out the CHINAPLAS on-site tour brought to you by PRM. Let Alice show everyone the charm of the CHINAPLAS. Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry. ->PRM booth number: 7G01

Sustainable Innovation of Blown Film Machine | KUNG HSING

The latest innovation of Three Layer Blown Film Machine is featured with 3 in 1 Gap Winder that combines Surface Type, Contact Drive Type and Gap Winding. We are pleased to invite Kung Hsing Machinery to share the insight of the Blow Film Industry with us, which includes application, ESG and the effect of geopolitic to the economy. 【Product Features】 ● Five layers co-extrusion blown film line ● Φ300 mm Die : Production output 600 kg / hr ● Gain in weight gravimetric dosing unit ( Italy made) ● Profile measurement & auto thickness control (Auto Air Ring-Height Adjustable, High Efficiency Cooling and High Output Rate, Germany made) ● IBC computer control system (U.S.A Made) ● Horizontal oscillating take-up unit ● 3 in 1 Gap winder ( Surface type, Contact Drive Type and Gap Winding) 【Video Outline】 0:00 Welcome to K 2022 0:24 Introduction of Kung Hsing Machinery 0:53 Highlights of Kung Hsing at K 2022 1:54 Applications of KS Blown Film Machines 2:34 Upgrade of Three Layer Blown Film Machine 5:38 Strategy and Implementation to ESG 6:51 Customer Oriented Service 7:54 Advantages of Taiwanese Supply Chain 8:54 Occurrences affect Global Market 10:04 Development Trends of KS Blown Film Machine 11:07 More information on PRM B2

Aluminum Foil Printing Techniques | WORLDLY

Have you ever wondered how essential it is for manufacturers and consumers to have the right packaging or sealing material on a decomposable product like medicine, snacks/drinks, or any other related product? By interviewing Klive from WORLDY, we have been explaining what kind of technical strengths Worldly has and they are capable of manufacturing and designing customization machines according to client's demand. Moreover, You will obtain the knowledge of the difference between plastic and aluminum foil to understand the applications of each materials.