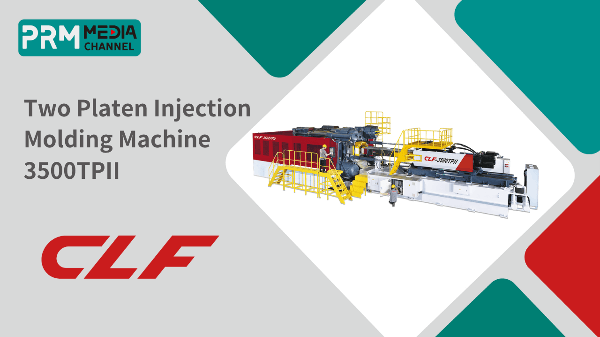

Two Platen Injection Molding Machine - 3500TPII | CLF-

➡️ Maximum injection weight 34 KG. ➡️ High stability, High efficiency, High energy saving.. ➡️ Electric Plasticizing Motor substantially increases production capacity and saves energy. ➡️ Direct pressure clamping to make the mold evenly stressed. ➡️ Smooth, stable and powerful. ➡️ Uniform tension force on tie bars for dramatic increase of service life. ➡️ Simplified construction with no wearing problem on toggle clamp. Via continuous challenging high-end injection machinery, CLF has success- fully invented the multi-circuit plastic injection machines, horizontal injection molding Machine, servo-driven hydraulic fully closed-loop controlled injection machine, multi-color/multi- resin injection molding machine, and etc.

What is Biodegradable Plastic & Bio-based Plastic | PRM What to Say EP9

What are the biodegradable plastics? Are biodegradable plastics recyclable? Are biodegrdable plastics environmentally friendly? What are the types of biodegradable plastics? Where to use biodegradable plastics? We heard your questions and made a research for you, looked for the answers of common questions about biodegradable plastics. We also evaluated difference and similarities of bio plastics and biodegradable plastics. Let's take a look at the video and find out more about these two types of materials!

Circular Loom Machine - 6 Shuttle Circular Looms | HAO YU

Introducing 6 Shuttle Circular Looms Machine from HAO YU. With HAO YU HY7-m6SCL six shuttles circular loom is designed with 6 shuttles to perform tubular weaving at high speed up to 180 RPM which is the highest technology in this woven bag equipment field in Asia. It reaches outputs up to 140 meters per hour. In case warp and weft breaks (finished), the machine stops automatically, An auto compensation system is also equipped to prevent the machine from empty weaving, it is an advanced circular loom specially designed to meet the stringent productivity requirements of today. The circular looms equipped with European inverter and high quality components. HAO YU is applying patent in Taiwan, China, India, and other countries. 【Machine Features】 Low spare part consumption & easy maintenance Energy saving nearly 50% over conventional models Large weft yarn insertion capacity up to 1080 PPM(max) Flat yarn applicable weaving denier from 500-1200(standard) Large weft yarn carriage capacity up to 115mm(max) Equipped with European inverter for main motor Lubrication-free for shuttle & cam 【Optional Accessories】 Gusseting device Both sides heat slitting device and additional fabric winder Center unfold device with heat slitting device and extra large unwinder for cement bag industry 【ABOUT HAO YU】 Hao Yu has been dedicated to manufacturing PP/PE/PET woven bag machinery and whole-plant equipment since its establishment in 1980. Enhancing present machinery and developing new models are Hao Yu’s objectives in order to improve the efficiency, product quality, and profitability for their customers.

The Cliff's Notes of Chinese Market | PRM What to Say EP2

We are very excited to announce that our general manager, Hero, went to China for CHINAPLAS 2021. It was our pleasure to invite him to PRM Media Channel to share Cliff's Notes on the Chinese Market. Hero mentioned the quarantine process, CHINAPLAS 2021 on-site observation, the escalating demand in China, and the recent Alibaba case in the Video. Moreover, Hero is surprised how the Chinese market digitized, which we should work on. Therefore we are working on creating a borderless environment for our viewers. VIDEO OUTLINE 0:00 Video Starts & Introduce our general manager, Hero 0:50 Experience of Quarantine Process 1:20 Insight into CHINAPLAS 2021 2:23 Domestic Demand in China 4:06 Changes in Chinese Lifestyle 5:44 Brief Talk about Alibaba Case Know us more on PRM YouTube:https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

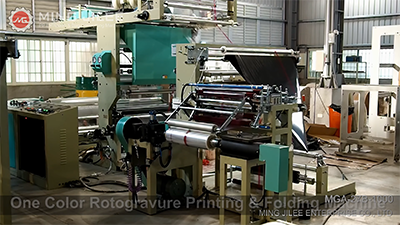

Triangle Folding Machine, 1 Color Rotogravure Printing | MING JILEE

Triangle Folding Machine, 1 Color Rotogravure Printing, MGA-27B-1000 from MING JILEE Specializes in Triangle folding machine , Ming Jilee Enterprise Co., Ltd. established in 1987 and received ISO-9002 approval for Triangle folding machine and exporter. Our Triangle folding machine products are all as our business policy: high-tech quality, competitive price, best service, on time delivery, and more for sealing and cutting machine services.

EPS Foam Sheet Machine | Plastic Extruder Manufacturer | ChiChang

EPS Foam Sheet Machine can be widely used in packaging materials, such as food trays, eps food Packaging. Learn more https://www.extrusion.com.tw/en/products.html Contact Us https://www.extrusion.com.tw/en/contact.html / EPS Foam Sheet Machine Features / Machines provide customized services. Application: Food Tray / Packaging Material. Output: From 200 kg/hr. to 720 kg/hr. for EPS. Configure a color screen to instantly view productivity. Safe and high quality. / About Chi Chang - Plastic Extrusion Machine Manufacturer / Chi Chang have been committed to the design and fabrication of extrusion equipment for over 45 years. Our user-friendly and performance-oriented innovative technology reduces the operating workload of workers, reduces the operating costs, increases the overall production capacity and this in turn generates more profit. You can rely on Chi Chang to simultaneously secure both profit and quality for our clients.

Co-rotating Twin Screw Extrusion | CYKF

Did you know that? Because of the low cost and material versatility, strand pelletizing is the most commonly used pelletizing system. Description: 1. Heating & Cooling System: The material can keep the best temperature in the manufacturing by alternatively using hot water and cold water. 2. Stable Feeding System: The designed screw can avoid material stuck and causing uneven feeding. The feeding quantity can be adusted according to needs. 3. Side Feeder: Used for adding additives including powder, liquid, or pellet type, the side feeder can arrange an automatic system that supplements additives by itself. 4. Vacuum Unit: Purify the pellet by getting rid of exhaust gas or steam from materials. 5. Water Cooling Unit: The water tank cooled the strand plastic, and the organized water tank remains the proper temperature to make the plastic straight and unbroken. 6. Dryer: The dryer removes water from the strand plastic surface with strong wind, and the removed water will return to the water tank eventually. 7. Pelletizer: The pelletizer cut strand plastic into pellets, and the rotate speed can adjust freely, customers can also change other models for bigger productivity. More product information please visit our website: https://www.cykf.com.tw/tw/product/Strand-Pelletizing-System.html

Water Transfer Printing Film and Equipment Manufacturer | YUAN HENG TAI-

Semi Automatic Hydro Dipping Machine with Lay film, Auto Spray Activator, and Production Arm. A powerful combination of all necessary important processes for WTP processing. From the very beginning laying, and the following activator spraying to the final dipping stage, done the main WTP process with only one button. This machine includes dipping tank, auto film layer and auto spray system. The combination of these 3 components not only makes WTP even simple, but more important– stable quality to the final product. The system can memorize multiple sets of different processes. This dipping machine is perfect for large product and medium quantities of production/day.

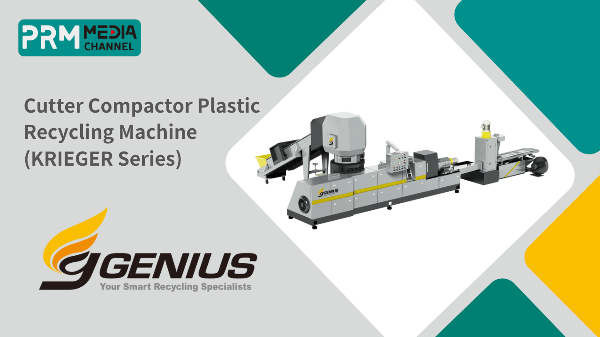

Customization & After-sale Service | GENIUS

More and more countries request all plastic-made products to be fully recycled; therefore, plastic recycling machines have been important. Mr. Peter Tsai, the general manager of Genius, explained the best seller “Single Stage Cutter Compactor Plastic Recycling Machine” as known as KRIEGER series in their product lines. This machine is capable of recycling HDPE drums and films with superior features, such as Italian-made heater, extruder-degassing vents, dual piston filters. With excellent customer satisfaction and customization service, Genius awarded an order from a returning Japanese client again. According to the language and the use habits, the parts of the machine have been installed with many Japanese brands in order to lessen obstacles while Japanese employees operate the machine. Moreover, Peter has expressed how Genius values customer satisfaction, customization service and after-sales service in the interview. Through this video, you will be showcased how Genius is running the testing of Single Cutter Compactor Machine before shipment. 【Brief Intro】 Genius Machinery specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipment. 【Video Outline】 00:00 - Introduction 00:31 - Machine Testing & Superior Features 02:10 - Conveyor Belt 02:19 - Compactor 02:50 - Extruder-degassing 03:19 - Dual Piston Filter 03:40 - Pelletizer 04:18 - Details of customized control panel 05:21 - Materials Process & Applications of Machine 06:27 - After-sale service for installation & maintenance 08:05 - Messages to customers

Quick Die Change | FORWELL

Quick Die Change - Quick Die Change System-qdcs-en-Forwell Features : • Decreased die change time • Designed for hydraulic and pneumatic presses • Increased efficiency • Reduced labor costs • Safer operations System Introduction : Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management. Quick Die Change Systems are becoming a standard for large manufacturers as they not only increase production efficiency, but also improve the overall working environment. The Automatic Die Change System can be built specifically for your machining requirements and will drastically reduce machine idle time during die changes, boosting your competitiveness. There are also a number of indirect benefits of installing a Quick Die Change System for your hydraulic and mechanical type press machines. Firstly, automated operations reduce labor expenses, but also reduce workshop accidents and the physical stresses on operators, making them more productive. Secondly, all dies can be changed without any modification allowing for the use of standardized die and press equipment, saving costs. Lastly, multiple presses can share a single Quick Die Change System, further economizing on costs and resulting in higher efficiency and productivity.

High Speed Side Sealing Machine with Wicketer | LIAN YOU

High Speed Side Sealing Machine with Wicketer

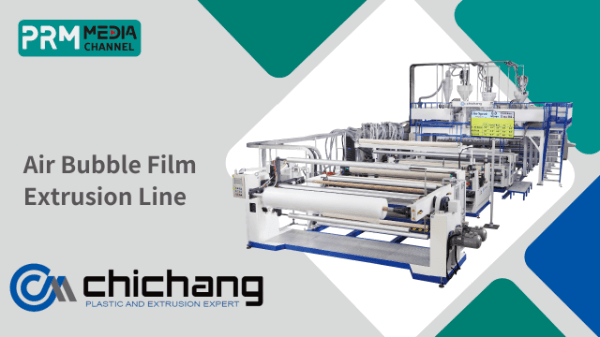

3 Layer Air Bubble Film Extrusion Line | CHI CHANG MACHINERY

【Applications】 The main uses of the Air Bubble Sheet are: Packaging of electronic material with anti-static additive. Agricultural sector (green house) with anti-UV additive. Covering of swimming pool with anti-UV additive. Typical packaging with anti-shock, anti-abrasion and anti-crushing functions. Laminated with paper, PE woven and aluminum foil for making envelope. 【Compnay Introduction】 Since our founding in 1972 CHI CHANG MACHINERY ENTERPRISE CO., LTD has been on a never-ending quest for breakthroughs and innovations in technology. CCM ensures that wherever our customers are in the world, all of our extrusion equipment and services reach outstanding levels of performance. Adhering to our motto of Integrity, Innovative technology and Sustainable services, CCM is dedicated to the design and fabrication of plastic extrusion machinery.

Proportional Valves for Plastic & Rubber Industry | KAO LU

KAO LU ENTERPRISES CO. is an professional Taiwanese manufacturer. With experience for over 40 years, it’s one of the leaders of the proportional pressure and flow control valves. With high-quality manufacturing techniques, their distributors spread all around the world. 【Video Outline】 Company Introduction Product Application & Competitiveness Product Introduction Main Customers Application on Medical and Biotech Equipment Application on Plastic and Rubber Equipment Advantages of the Era of Industry 4.0 Contact Information

Injection Molding Solution | Plastic Injection Molding Machine Manufacturer | CLF

Chuan Lih Fa Injection Molding Machine at steady development of injection molding fields. With strict standards of the quality and the clamping force of the machines, combining high-tech European and Japanese microcomputer controllers, our electric injection molding machine adopts German Siemens controlling system as well as servo motors. The innovative structural design makes Chuan Lih Fa a leader in this industry.

CHINAPLAS On-site Tour Hall No.1-6 | PRM-TAIWAN

Hello everyone! It's been a long time since last CHINAPLAS Let one of partner from PRM—— Joey Show you all the fantastic things at CHINAPLAS Welcome to PRM's booth if you are interested in the first-hand marketing and trade news of the Plastic and Rubber industry.

PP Woven Bag Fully Automatic Liner Inserting-Bag Top Hemming Conversion Line | BOTHEVEN

【MAIN FEATURE】 All in one multi-functional machine - Flexible Usage for various type of PP woven bag Processing on the same machine. Available for PP woven bags: ● With liner Inserting-Cutting-Sewing and bag top hemming process ● With Cutting-Sewing and Bag Top Hemming Process Only (Without Liner Inserting) ● With Liner Inserting-Cutting-Sewing Only (Without Bag Top Hemming process) Cutting-Sewing Process only (Without Liner Inserting & Without Bag Top Hemming) Saving Manpower, Space and Saving Cultivated Training for Skilled Manual Operation to the Maximum. Producing Finished Bags with Conformed & unified quality with stable performance Experiencing Clean Process of Bag Top Hemming, largely Reducing Hang-Touching on the bag top area. Highly synchronized machine for Easy Setup and quick bag size changeover. A Total-Solution Machine for PP woven bags with Final Products Applicable in a Big Variety Market. 【COMPANY INTRO】 Botheven Machinery Industrial Co., Ltd, (Since 1984), has accumulated more than 30 years of technical experience & know-how in the planning design, manufacturing, sales and service of PP/HDPE Woven Bag Making Machines in Taiwan. Our equipment has been sold worldwide with assured quality, stable performance and reliable after-sales services. We can build machinery according to customers' requirement; also provide cost-down solution for customers.

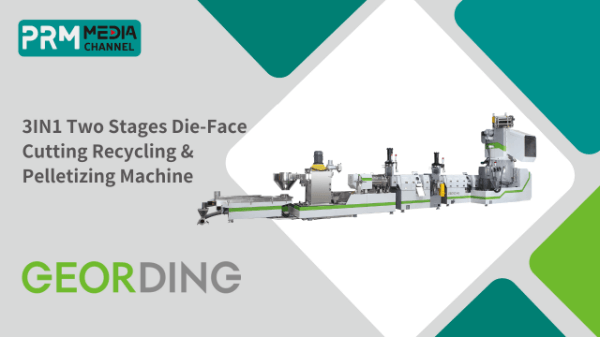

Plastic Recycling & Pelletizing Machine | GEORDING

【Product Line】 Plastic recycling machine Compounding machine Dyeing & Pelletizing Automatic batch weighing and mixing system Washing line Rubbing drying machine Powerful crusher Shredder Plastic flat board extruder Refuse derived fuel (RDF) 【Company Intro】 GEORDING MACHINERY CO., LTD. has dedicated to innovating their machines with superior features which can process various plastic materials, such as PA, PET, ABS, TPU, Calcium Carbonate and even PE foam. By keeping developing and improving their technology, GEORDING has become one of the leaders of the extruder supplier as well.

High Speed Slitting Machine - S2A Series | YICHEEN

YICHEEN is a professional equipment supplier that specializes in soft-material cutting technology, including die cutting, sheet cutting, slitting and laminating. Since 1979 we have been supplying soft material cutting machinery. This has now transformed into state of the art high-precision customized cutting equipment, which meets worldwide standards and guidelines.

PRM Media Channel at TAIPEI PACK 2020

TAIPEI PACK once again is held in December 2020 at Taipei City, Nangang Exhibition Hall 1. PRM Media Channel was on the field to share insight into the packaging industry. In 2020 many large exhibitions in the world have been forced to cancel/postpone due to the global pandemic. Thanks to Taiwan's relatively safer environment, TAIPEI PACK successfully launched as a combination of six different Exhibitions in one. There are more than 900 domestic and international exhibitors on-site waiting to meet the visitors. Moreover, there are many online on-site exhibitions and conferences scheduled for the interest of global visitors. During the exhibition, PRM Media Channel conducted interviews with the exhibitor to gather insights into the industry. Stay tuned for the forthcoming interview videos and remember to subscribe to PRM Media Channel!~

2024 CHINAPLAS Interview | ABIMAQ SINDIMAQ

It’s our great honor to interview Mr. Marcelo Zimmaro, Machinery and Accessories Sectorial Chamber for the Plastic Industry from ABIMAQ SINDIMAQ Brazil. In this interview, Jason asked him about ABIMAQ's services and business scope, his views on the economic situation in Latin America in recent years, and his expectations for this exhibition in China. Mr. Marcelo Zimmaro stated that their mission at the exhibition is to assist the Brazilian machinery industry in import and export activities, and they hope to find more allies and friends at this exhibition. For more detailed interview content, please stay tuned for the upcoming PRM reports. PRM is committed to collaborating with global media to bring more information about the world's plastics and rubber industry to everyone.

Food Processing Machine Solutions | HUNDRED MACHINERY

Since 1996, Hundred Machinery Co., Ltd. has been the professional automatic encrusting machine manufacturer in Taiwan. PRM Media Channel had an interview at the recent TAIPEI PACK and had a chance to introduces the companies automatic food processing machinery lines. Let us know your opinion and the inquiry in the comment section. Stay tuned for the forthcoming interview videos and remember to subscribe to our social media channels for similar videos!~ MAIN PRODUCTS/SERVICES OF HUNDRED MACHINERY:

Seaming Machine | WEBCONTROL

Seaming Machine-300(K2)-Webcontrol Webcontrol Machinery Corp has been specializing in manufacture of Seaming Machine since 1988. Webcontrol ceaselessly develop new machine to extend production line for meeting various needs of customers. In additions, we constantly improve our Seaming Machine with new technology, and innovate to enhances its performance, efficiency and reducing waste on production. Our consistently aim is to build high-performance, sophisticated Converting Machinery with inexpensive price as well as providing fast Seaming Machine service ensure our worldwide customers must be satisfied.

WEI MENG | WMD Onion Bag Making Machine

Our Double Needle Bar Raschel Machine is the perfect solution for businesses that need to produce high-quality, high-speed packing sacks. With a working width of 170 inches and gauges of 2 - 6 needles per inch, this machine can produce a variety of nets for different purposes. It is also ideal for producing onion bag machines, special wide nets, and double-layered nets. This machine is equipped with a high-speed warp supply system that ensures that your nets are produced quickly and efficiently. It also has a number of features that make it easy to use, including a user-friendly control panel and an automatic yarn tensioning system. If you are looking for a high-quality, high-speed Double Needle Bar Raschel Machine, then our machine is the perfect choice for you. Contact us today to learn more about our machines and how they can help your business. Double Needle Bar Raschel Machine is specially designed for onion bag and double layer nets making. This machine is applicable Yarn is HDPE flat yarn and monofilaments. Standard gauges machine 2 - 6 needle per inch, Maximum performance of the machine can up to 600rpm.

T-Shirt Bag Making Line with Carton Packaging Line|JIT-SS 4 sets full auto. in-line|JANDI'S

#PlasticReuse #MachineManufacturer #PlasticRecyclingMachine 00:00 Opening 00:08 Blown Film 00:28 Machine current speed 00:37 Cutting, Sealing & Punching 00:54 Sending finished bag to Carton Packaging Section 01:07 Take-up Tower & Printing 02:27 Carton Packaging Proccess 05:04 Ending --- Website : www.jandis.com.tw & www.inflationmachine.com Facebook : www.facebook.com/JANDIS.JIT Email : [email protected]

Packaging Industry Trends and Obstacles | PRM What to Say EP5

In the fifth episode of the PRM What to Say program we interview Ms. Wang, the Chairperson of Taiwan Packaging Association. Through the interview that our team member Sunny held, we touched several current topics related to the packaging industry, online and physical trade shows, food food safety, shelf life and modern packaging designs, the association’s support for the members and so on. Since the beginning of the outbreak many machinery industries are facing several common obstacles such as logistics, machinery installation and maintenance. For the many machinery categories, the demands are suspended. However, for the packaging industry, the situation is more specific. Due to the global lock downs, the housing economy has been revived and the needs for food packaging and cargo packaging boomed. On the other hand, the machine manufacturers are still facing the common obstacles of the pandemic to reach out to their customers.

K 2022 ON-SITE TOUR | PRM

Can't attend K 2022 in person? PRM will show you the most interesting exhibition highlights on【K SHOW 2022 ON-SITE TOUR】 Taiwanese manufacturers are gathering at K 2022 and showcasing their new technique of plastic & rubber machinery. You can also feel the good vibe from the show. 【Video Outline】 0:00 Introduction 0:16 CHAO WEI PLASTIC MACHINERY | Plastic Converting Machines 0:37 YE I MACHINERY | Plastic Recycling & Material Processing Machinery 1:36 HO HSING PRECISION INDUSTRY | Parts and Components 2:06 HUARONG GROUP | Injection Molding Machines 2:50 SUNKIST CHEMICAL MACHINERY | Thermoforming Machines 3:17 MING JILEE ENTERPRISE| Extruders & Extrusion Lines 3:41 QUEEN’S MACHINERY | Extruders & Extrusion Lines 3:52 CHI CHANG MACHINERY | Extruders & Extrusion Lines 4:17 HSIN LONG | Molds & Dies 4:38 FORMAX | Auxiliary Equipment and Integrated Automation 4:46 YEN SHENG MACHINERY | Extruders & Extrusion Lines 5:01 BOTHEVEN MACHINERY | Auxiliary Equipment and Integrated Automation 5:20 GENIUS | Plastic Recycling & Material Processing Machinery 5:40 JUMBO STEEL | Extruders & Extrusion Lines 6:10 WORLDLY INDUSTRIAL | Printing Machinery 7:00 PRM TAIWAN

Three Layer Blown Film Extruder Plastic Inflation Machine | KANG CHYAU-

THREE LAYER BLOWN FILM EXTRUDER PLASTIC INFLATION MACHINE MODEL: KMTL-55-65-55 E3 Screw/Barrel: 55-65-55 mm Roller width: 1600mm Film width: 1400mm Film thickness: 30mic

Hydraulic Die Cutting Machine (HDR 0505) | Yicheen

Yicheen specializes in manufacturing Rewinding Hydraulic Die Cutting, which high speed sliding table feeding, motion is fast and safe.

2024 InterPlas Thailand Interview | Chang Horing

We had the pleasure of interviewing Chang Horing Rubber Group, a leader in the rubber compound industry with over 20 years of experience, at Thailand InterPlas 2024. In this engaging conversation, they shared their expertise in developing and customizing rubber compounds for various industries, including automotive, chemical, heavy-duty, food, and water sectors. Chang Horing's dedication to quality and precision is evident in their state-of-the-art facilities, equipped with advanced systems and instruments to ensure high-quality consistency. They also discussed their future plans and initiatives related to Environmental, Social, and Governance (ESG) practices, highlighting their commitment to sustainability and innovation. We thank Chang Horing Rubber Group for sharing their valuable information and look forward to seeing their continued success in the industry.

International Market Outlook | PRM What to Say EP3

International Market Outlook | PRM What to Say EP3 In this episode, we are talking about Taiwanese stock prices and machinery export. Moreover, the price of raw materials has been rising for many months in accordance with many factors, which will be mentioned as well, such as marine logistics, Texas blackout, and so on. During the tough period of the pandemic, we will go through how Taiwanese manufacturers cope with problems to serve their customers and what they are planning to do. Wish everyone to stay safe and healthy to fight and overcome this circumstance. Know us more on: PRM YouTube: https://www.youtube.com/c/PRMTaiwan PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/ VIDEO OUTLINE 0:00 Highlights in Episode 3 & Video Intro 0:45 Stock Prices & Machinery Export in Taiwan 2:28 Reasons for Price Change of Raw Materials 5:09 When Raw Materials Prices Come Back to Normal? 7:37 Vaccine & Current Situation in Taiwan

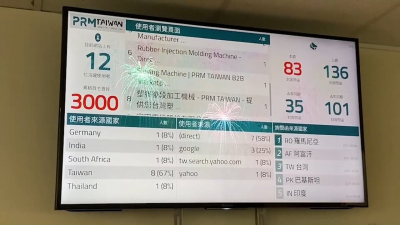

Thanks to 3000+ Members of PRM-TAIWAN B2B Platform

【Thanks to 3000+ Members of PRM-TAIWAN B2B Platform】 See Membership Benefits: https://bit.ly/3tVXnSr We would like to thank all of our supporters and our 3000 MEMBERS of PRM-TAIWAN B2B Platform for putting your trust in us and help us reach this milestone!!! We will do what we have to do, serve every customer with the most updated information and match you with the most suitable Plastics and Rubber supplier for you!

PRM Buyer Guide | PRM-TAIWAN

We have over 200 of the biggest and many of the small and medium-sized Taiwanese machinery manufacturers on our site and contacts with many more. Whether you are looking for full lines such as recycling machines extruders, blow molding machines, injection molding machines and printing machines, or auxiliary equipment and parts such as gearboxes, barrels, screws, molds, dies, control systems, and virtually anything related to the plastic and rubber industries including packaging. If it’s made in Taiwan, we will find it for you!

How 2025 U.S. Tariffs Will Reshape the Plastics Industry | PRM What To Say EP20

In this episode of PRM What To Say (EP20), we dive into the latest developments of the 2025 U.S. tariff policy and its profound impact on the plastics industry. What do the new 245% tariffs on China mean for global supply chains? How will Taiwan, Japan, Korea, and Europe be affected? Join us as we analyze the key changes, challenges, and future opportunities for plastics manufacturers worldwide. Topics Covered: U.S. reciprocal tariffs overview Strategic moves for manufacturers in 2025 Don't forget to subscribe for more insights on global trade, plastics machinery, and industry trends!

Cutter Compactor Plastic Recycling Machine (KRIEGER Series) | GENIUS

The KRIEGER series cutter compactor plastic recycling machine integrates crushing, extruding and pelletizing in one machine. A proprietary designed cutter compactor can compact the density of fluffy plastic film to flakes. It helps to increase the efficiency of extruder. After compactor, the materials are extruded to Genius patented universal joint pelletizing system. The universal joint pelletizing system can automatically adjust the distance when cutting the polymer to pellets. Significantly reduces manual adjustment error rates. After cooling, these pellets are sent to centrifugal dryer to remove moisture. A vibrator at next step removes powders or oversized pellets. Finally, recycled pellets can be reused in different fields, for example, blow film or injection molding industries. / Key Features of Cutter Compactor Plastic Recycling Machine / Energy cost saves up to 20% Only 1~2 operators are needed to operate the pp recycling machine. High-speed rotation operation makes the fluffy material compact. Simultaneous material dewatering. Triple cooling sections – air cooling system, compactor body water cooling system, and water spraying system. The temperature control is convenient, and the temperature of the crushing barrel is controlled in a stable manner. Provide customized recycling, sorting, feeding, degassing, filtering, granulating to storage and packaging systems.

2024 CHINAPLAS Interview | CHINAPLAS

We are here with Ms. Ada from the CHINAPLAS. She also shared very useful information about the forthcoming CHINAPLAS 2024 including the focus of the exhibition.

Five-Layer Extruder & Cutting Machine | BONMART

【Machine Features】 Plastic material has its own characters. In co-extrusion system. BONMART uses and combines several kinds of materials, therefore, the characters of single layer tube can't compete with the complex characters of co-extrusion tube. Glossy surface (using: EVOH / RESIN / PE)Extensive color combination (using: PE + PEARL / PE + PIGMENT)Excellent barrier property (using: PE / TIE RESIN / EVOH / TIE RESIN / PE) Scratch and dust free (using: LDPE / LDPE / LLDPE)Co-extrusion is used on pesticide container, toothpaste, side window, multicolor, long preservative cosmetic... etc. 【Company Intro】 BONMART offers complete-line including technology transfer, cost analysis, layout, installation, test run, training and satisfactory after sale services. Using our Squeezable PE Tube equipment is the best choice of good investment, Welcome to contact us for more details any time.

Business Tips of Choosing Plastic Recycling Machine | PRM What To Say EP17

Do you understand different kind of plastic recycling machines? Each type of plastic could be processed by certain type of machine. If you are still confused in choosing machines for your business, you must watch this video.

Core Objects for Plastic & Rubber Machines | NAN YUN

Do you know SCREWS and BARRELS? Those are dispensable parts to injection molding machines, extruders and relevant machines in the plastic and rubber industry. Nan Yun Industrial Co., LTD., an expert who specializes in designing and manufacturing a full range of screws and barrels. With more than 30 years of experience, Nan Yun’s team provides customization services to meet customer’s special applications. By interviewing Mr. Kuo-Feng Huang, Assistant Manager of ST Dept., we also discussed an important engineering technology concept “Reverse Engineering” and how Nan Yun applied it into their business. Moreover, after-sales service is one of Nan Yun’s values. By Gathering feedback and reviewing consultation forms in past years, they could provide accurate solutions to their customers. 【Video Outline】 00:00 - Introduction 00:45 - The role of Nan Yun 01:22 - The specialty of Nan Yun 03:03 - Service during the pandemic 03:37 - Solutions to customer’s problems 04:25 - Future plans and messages to customers 05:23 - Closing

U Liner Bag Making Machine SHCG-75U | SING SIANG

SING SIANG MACHINERY CO., LTD

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT

Robot Arm, Take Out Robot, Injection Robot | ALFA ROBOT Originated from the parent company Alfa Auto Machinery Co., Ltd, Gamma is established based on the specific needs of customers. The chairman of ALFA, Mr. Shi Fuxing founded Dongguan Gmtek Technology Limited and Suzhou Gamma Automation Tech Co., Ltd in 2006 with the foundation of 2 million US dollars. The main services of Gamma are precision machining and professionally developed and manufactured high speed vertical machining center. Since the establishment, Gamma strives to fulfill the requirements of the customer and continue to provide the customers with the best service no matter if it’s precision, machining speed , the cost performance or the flatness.

CHINAPLAS 2021 PRM Trade Show Activities | PRM Media Channel

Throwback to CHINAPLAS 2021 to share the online and offline events of PRM. More Info About PRM Online Exhibition: https://bit.ly/3f1UN8t Let's take a look at PRM Trade Show Activities related to this biggest plastics and rubber industry exhibition in Asia. It was our pleasure to attend CHINAPLAS 2021 this year. Since the pandemic, the foreign visitors and exhibitors have been fewer than in previous years; however, PRM understands our customers' and international buyers' circumstances. In this video, you will find our exhibition activities, including matchmaking buyers and manufacturers of the plastics and rubber industry through our in-time inquiry system. During the exhibition, PRM observed the Chinese market and CHINAPLAS, also we have interviewed exhibitors to gather more profound insight into the market. You can find detailed information on our Youtube Channel, E-newsletter, and social media platforms that are provided below. We also cooperated with Adsale, the organizer of CHINAPLAS, to bring out interview videos and the Livestreams about the current situation of the plastics and rubber industry and their solutions. For more information and videos, please visit our PRM-TAIWAN TechHub@CPRJ at https://bit.ly/3f1UN8t Follow PRM Media Channel on: YouTube: https://www.youtube.com/c/PRMTaiwan Facebook: https://www.facebook.com/PRMTAIWAN Linkedin: https://www.linkedin.com/company/prm-taiwan/

Bag on Roll Making Machine | COSMO

COSMO has many years of experience in bag making machines. We are still willing to have much more improvement and all the consumers are satisfied with the quality of machines offered to you. 【Machine Features】 2 lines coreless star sealed bag on roll making machine Oscillation film feeding & sealing system for stability and high out put Automatically reel changing system High production efficiency to save manpower and time Servo motor, as standard attachment, makes it easy to adjust the bag length and the production speed Computer control over the entire process From film roll to final bag, non-stop, one process flow Automatically stop when running out of film/ film feeding blocks or bags jam/ color scanning misses 【Company Introduction】 COSMO Machinery Co., Ltd. established in March 2001, is well-known for Taiwan manufacturing plastic bag making machinery with servo driving systems. The product from COSMO has the servo motor as standard attachment, makes it easy to adjust the bag length and the production speed, computer control over the entire process, component self-testing function available, high production efficiency to save manpower and time. Up to now, COSMO products are extensively exported to 100 countries spreading all over the world.

CHINAPLAS 2021 Organizer Interview | PRM Media Channel

Recently despite many exhibitions that have been canceled or postponed, CHINAPLAS 2021 successfully made the event to be held on time, April 13th to 16th, 2021. In this manner, PRM Media Channel has conducted an online interview with Ms. Ada Leung, the General Manager of Adsale Exhibition Services Ltd., the organizer of CHINAPLAS. Ms. Ada Leung sincerely replied to our questions about this special event at a special time due to the pandemic. She also shared very useful information about the forthcoming CHINAPLAS 2021 including the focus of the exhibition, online activities for the visitors who cannot attend the exhibition, future plan of CHINAPLAS through digitalization and hybrid exhibition model. Let's take a look at the interview video to learn more, and let us know your opinions and questions.

HDPE Drum Plastic Recycling Machine ft. Chemical Drum Pelletizing System | GENIUS

Compacting & feeding The high speed compactor creates superior efficiency friction heat to compact the fluffy materials. Removed moisture during processed. Increase the highest throughputs for more productivity. Multiple Cooling Triple cooling sections – air cooling system, compactor body water cooling system and water spraying system. The operator can set the temperature of each to stably control the compactor's temperature. Better Flexibility Genius recycling specialist team provides customized recycling systems, flexible options from sorting, feeding, degassing, filtration, to storage and packing systems. According to the clients' needs presenting a smart and reliable plant. Cost Saving Energy cost saves up to 20%. Labor cost is reduces as only 1~2 operators are needed to operate the whole plant. 【Company Introduction】 Genius Machinery Co., Ltd. specializes in the comprehensive plant planning of plastic recycling equipment. With over 40 years of experience in designing and manufacturing plastic recycling equipments. Since its establishment, Genius Machinery Co., Ltd. has provided industries with plastic washing lines, plastic recycling machines, pelletizers, plastic squeeze dryers, crushers, shredders, and other complete series of manufacture line for one-stop services.

All Electric Molding Machine | CLF

All Electric Injection Molding Machine Features: ⚫Electricity Regeneration Circuit Electricity Saved by 15% ⚫Employs German Siemens control and servo motors for excellent performance and high accuracy. ⚫High performance injection unit that enhances the exceptional features of servo control.High speed,stability and accuracy are guaranteed. ⚫In-house software development capability combined with technical support from Siemens. ⚫Standardized hardware design simplifies the maintenance works and reduces the spare parts stock. ⚫Simultaneous control on multi-axes shortens molding cycle time dramatically. ⚫Overall super rigid structure minimizes running vibration. ⚫Exclusive energy-regeneration function not only provides electricity-saving and environmental protection, but also meets today's trend of energy-saving. ⚫Ergonomics operation interface. ⚫The access level to controller management can be ranked. ⚫Rigid platen design exhibits superior parallelism. ⚫Supports remote monitoring functions.

All electric blow moulding 20L jerrycan energy saving, no hydraulic oil, no pollution, industry 4.0 | FONG KEE

Model No : FK/EHB-55G-100G-55GT20SD Energy Saving Power consumption 40~50%↓ Production output 20~25%↑ ECO No hydraulic oil, no pollution, Noise level 20dB reduced. Industry 4.0 Smart manufacturing, with SCADA system.

Quick Die Change System | FORWELL

Forwell’s Quick Die Change System is an automatic die changing system that can be specifically designed for hydraulic and mechanical power presses and press production lines. This system automates the die changing process and provides increased speed, efficiency and productivity to a workshop. The Quick Die Change System not only reduces die change time, but also promotes diverse small batch production runs and streamlines production management.