ABA Blown Film Machine (JC-ABA) | PLASCO

PLASCO's JC-ABA Series of 3-layer co-extrusion blown film lines are the ultimate economic and environmental solutions for multi-layer blown film production. 【Machine Spec】 Applicable Material: LDPE / LLDPE / MDPE / HDPE Screw Diameter (mm): "45/55", "50/55", "55/75" Film Layflat Width (mm): 800 / 1000 / 1200 Film Thickness (mm): 0.015-0.10 Extrusion Capacity (kg/hr): 100 / 160 / 250 【Application】 Express Bag Plant Bag Shopping Bag T-shirt Bag Laundry Bag Garbage Bag 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

Flexo Printing Machine Stack Type - Double Side 2+2 | ROTOFLEXO

ROTOFLEXO Stack Type Flexo Printing Machine - 250 M MIN - Double Side 2+2 - High precision cylinders, anilox rollers, and guiding rollers - Automatic temperature control system - High precision gear transmission system - Closed chamber doctor blade system - Automatic tension, edge, and web guide control - High speed forward and reverse printing desk motion - High precision ball screw designs for key components - Motorised horizontal and longitudinal registration system - Electric heat/drying system - CNC desk position control

Plastic Injection Molding Innovations and Green Solutions | KING'S SOLUTION

Livestream time: November 20th at 19: 00 (GMT +8, Taipei) The Livestream that PRM Media Channel held with KING'S SOLUTION CORP. with the title of Plastic Injection Molding Innovations and Green Solutions brings you new insight into the injection molding machine industry. Remember to direct your questions in the live chat section, KING'S SOLUTION and PRM Media Channel will be replying to your questions. What are the challenges, trends, and innovations in the injection molding industry? How to sustain after-sales services during post-pandemic? What advantages LPM (Low-Pressure Molding) brings to the manufacturers compared to Epoxy Injection Molding? Do you also have similar questions like that or would like to learn more? Then we welcome you to watch the Livestream video on November 20th at 19: 00 (GMT +8, Taipei) 【VIDEO OUTLINE】 00:00 Opening 00:59 KING'S SOLUTION CORPORATION 02:00 "Green Solution, Machine Soulmate" Slogan 03:04 Why to customize the machines? 05:00 Customized Machine Series 06:00 Market Challenges and Successful Cases 10:38 5 Gallon PET Preform Injection Molding Solutions 12:35 Advantages of KING’S in 5 Gallon PET Preforms 16:16 Trends in Injection Molding Market 18:40 LPM Application Examples 23:00 LPM Method vs Epoxy Method 26:00 After Sales Services and Customer Relations 28:55 Message to Current and Potential Customers Know PRM Media Channel more on: PRM Media Channel Website: https://bit.ly/3uqdubs PRM Facebook: https://www.facebook.com/PRMMediaChannel PRM LinkedIn: https://www.linkedin.com/company/prm-taiwan/

Company Profile of Parker Plastic Machinery | PARKER

PARKER PLASTIC MACHINERY CO., LTD., established in 1989 in Taiwan, is a leading manufacturer specializing in turnkey solutions for blow molding machines. We offer a comprehensive range of high-performance extrusion equipment capable of handling capacities from 5cc to 220L drums. Our commitment to precision and reliability ensures that we consistently meet the diverse needs of our global clientele with excellence. At PARKER, we provide complete technical support, from initial consultations and customized training to ongoing service. Our expert team analyzes production requirements, conducts detailed project studies, and excels in comprehensive blow mold plant planning, optimizing operations for efficiency and profitability. Recognized for superior product quality and exceptional after-sales service, PARKER PLASTIC MACHINERY CO., LTD. has cultivated trusted partnerships spanning over 35 years. Our dedication to excellence is backed by stringent ISO certifications and rigorous internal controls, ensuring consistently high standards. We prioritize customer satisfaction through dedicated support, adding substantial value to our enduring relationships. PARKER continues to innovate in the blow molding industry, advancing technology to enhance machine performance globally. Our machines are trusted across 5 continents and over 113 countries. Our professional sales and service engineers provide prompt and reliable support to meet your needs. PARKER - your trusted partner for high-quality blow molding machines in Taiwan.

2024 NPE Orlando Interview | PARKER

We had the pleasure of meeting the passionate Mr. CT Teoh at the NPE show. Mr. Teoh gave us an insightful overview of the innovative PET blow molding machine he brought to the event. This cutting-edge machine features single material concept. Join us as we dive into the details and discover the big news Mr. Teoh has to share!

Accumulator Blow Moulding Machine | CHEN WAY

CHEN WAY machinery is a specialized manufacturer in Taiwan that keeps focusing on the customized R & D for blow molding machines since 1990. Our blow molding machine produces mainly hollow plastic vessels ranging from 20ML to 2000L. Every machine is tested rigorously according to the customer production requirement, this process ensures that every machine can run with its maximum effectiveness. Detail Specifications : The Abl Series Blow Moulding Machines Are Particularly For Producing The Jerry Can/Drum Tank/Large Article Produtions.It Can Be Combined With Some Accessory Equipments To Increase The Efficiency And Expand The Functions, Such As: After Cooling Unit/Auto Deflashing Unit. The Die Head Can Stock The Melting Resin And Purge The Material For Blowing Formed It Designed With Two Heart Flow Chnnels.Can Make Welding Line-Free To Increase The Strength Of Production. The Tie Bar-Less Clamping Unit Is Consist Of Stiffness Structure Frame And Guiding Devices.Make Sure Deflection-Free Advantage. Also Devise With Precision Rack GgearsO of Bboth Side.Make Synchronize Moving Of Plates. The Blowpin Unit Is Designed For Production Calibrating. That Will Be Suited For Different Demand Of Customer. Accumulator Die Head Blow Moulding Machine. GEFRAN CONTROL SYSTEM -PID Temperature Control System (With High/Low Alarm) -Motor PID Feedback Control Function -300 Points Parison Control -PLC Ladder Program Edlitor -Presscription Record Memory Accumulator Die Head Blow Moulding Machine AUTO-DEFLASHING UNIT This Unit Can Be Excuted Top/Bottom/Handle Deflashing Function By Hydraulic And Pneumatic. And Then Used With Suction Device To Take Out And Turn Over The Production.

Industry Insight: Blow Molding Machine and Printing Machine Market India

KYMC on PRM-TAIWAN B2B Platform: https://bit.ly/3l2uZdT CHEN WAY on PRM-TAIWAN B2B Platform: https://bit.ly/3l3cqGz It was a nice interview with Mr. Kunal Mehta, who is from KYMC India and also the agent of CHEN WAY in India. At this interview, Mr. Kunal willingly shared the advantages of having a local partner in India, suggestions to foreign manufacturers/companies who plan to enter the Indian market, and how manufacturers provide support to local dealers under pandemic circumstances. Moreover, we also discussed the pros and cons of physical and online exhibitions. Let's watch the interview video together and leave your comment in the comment section!

Fibrillated Tape Extrusion Line (JC-FYB) | PLASCO

PLASCO's JC-FYB Series of extrusion lines are designed to produce either standard or heavy-duty fibrillated tape for technical end-use applications, such as baler twine, insulated cable filler, carpet backing, synthetic grass, and more! 【Machine Spec】 Applicable Materials: PP / HDPE Screw Diameter (mm): 85 / 100 / 110 Denier (D): 3000-25000 / 3000-30000 / 3000-35000 Working Width (mm): 800 / 1000 / 1200 Extrusion Capacity (kg/hr): 120 / 200 /250 【Application】 Rope Cable filler Baler twine 【Company Intro】 PLASCO is a global industry leader in the design, manufacture, and supply of innovative plastic extrusion lines. They specialize in applying innovative engineering concepts to the design and manufacture of plastic extrusion lines with more than 30 year experiences.

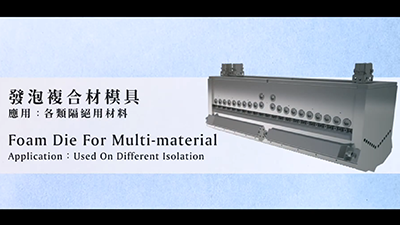

Extrusion Die - Foam Die For Multi-materials | GMA

Extrusion Die - Foam Die For Multi-materials | GMA Offers a variety of extrusion die. GMA MACHINERY ENTERPRISE was established in 1989. GMA specialized in extrusion die, T-Die extrusion, feedblock, melt pump, screen changer, slot die, vacuum box, air knife, static mixer. To meet extruding processor requirements, in 1990, GMA became involved in T-die design and manufacturing for sheet, film and coating film production. Over the years, we have invited several high molecular masters and doctors to research and develop various T-die manufacturing technology. GMA extrusion die, T-Die extrusion, feedblock, melt pump, screen changer, slot die, vacuum box, air knife, static mixer, GMA products have been sold to worldwide markets, such as: the U.K., Japan, the U.S.A., Italy, Brazil, Argentina and China, etc. We can offer best quality which can reach American and Japan level.

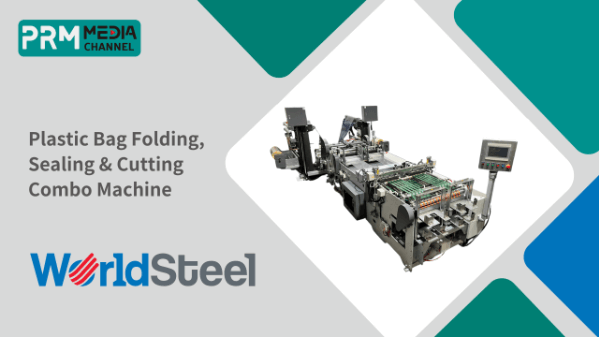

Plastic Bag Folding, Sealing & Cutting Combo Machine

World Steel Machinery Company is located in Taichung City, Taiwan. With over 35 years of experience, they are dedicated to making technological innovations and manufacturing packaging machines. World Steel on PRM: https://www.prm-taiwan.com/shorturl/Qrm7p5Qg