CHEN WAY: How is a Sports Water Bottle Made by Extrusion Blow Molding?

When we talk about everyday use products, we can mention different examples such as sports water bottles, which are in almost everyone's daily life: besides ensuring individuals stay hydrated throughout the day, they also eliminate the need for disposable, single-use bottles which are known for polluting the oceans.

GMA: Chinaplas, a New Opportunity to Meet Customers and Showcase Latest Developments and Technologies

Last year Chinaplas was held in Shenzhen, being the second year of the pandemic the situation made the number of people relatively small in comparison with previous editions, also most of the visitors were local.

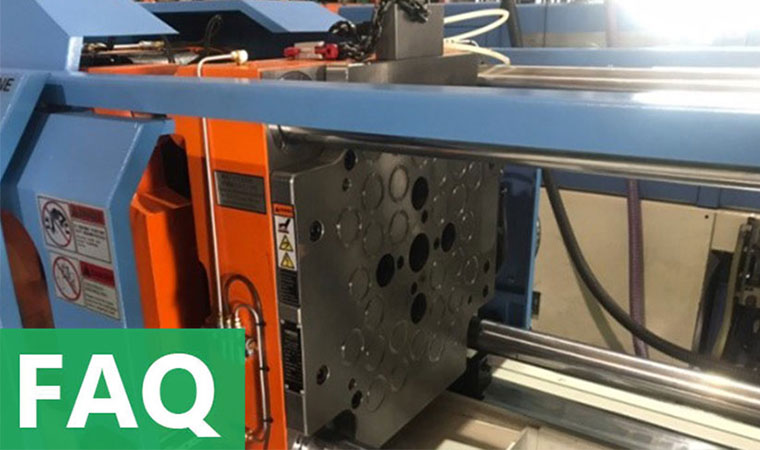

TungYu: Horizontal Rubber Injection Molding Machine

How to save material and increase productivity simultaneously? Horizontal rubber injection molding machine can contribute to reduce material waste and optimize automation. Tung Yu makes our effort to serve the best solution for customer.

CHEN WAY - How to Select the Correct Blow Molding Material for Your Products

Extrusion blow molding machines can produce a wide variety of hollow plastic products. It is important to keep in mind that in order to produce exceptional products, besides purchasing high-quality Blow Molding Machines, it is also crucial to choose the correct blow molding material for each project. This ensures that the end products will have the desired properties and will also be able to withstand the environment(s) that they will be exposed to.

What to Expect in 2022 for LIN CHENG’s Strategy and Performance for their Rubber Injection Molding Machinery

For more than four decades Lin Cheng Technologies has shown its great expertise around the world on the run of providing Customized Solutions, Rubber Injection molding machines, Silicone rubber injection machines, vacuum hot press injection molding machines and other types of hot press injection molding machines to the Industry.

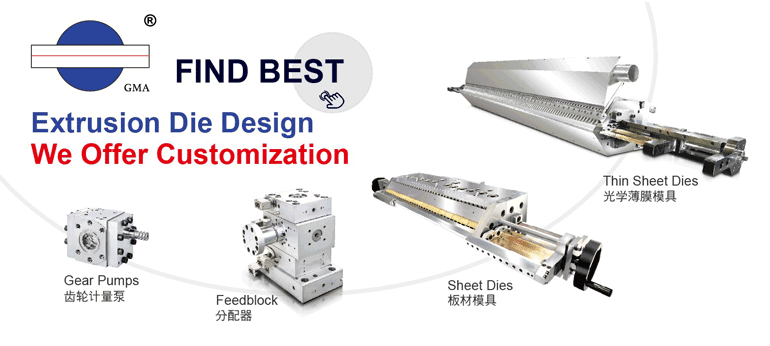

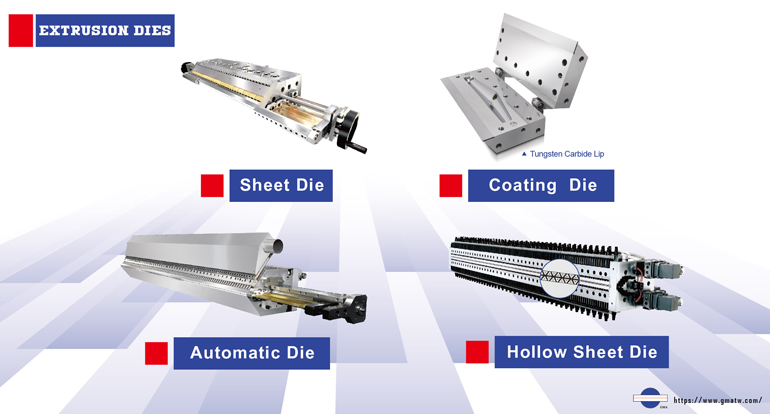

Why to Choose GMA’s Extrusion Dies?

It is well known the importance of high quality and high precision when we talk about Molds and Dies. GMA is one of the worldwide leaders of the industry, last year they became a really important actor, due the capacity of high production of Melt blown Dies, an indispensable component when it came to production of masks, which became a “must” in our daily life.

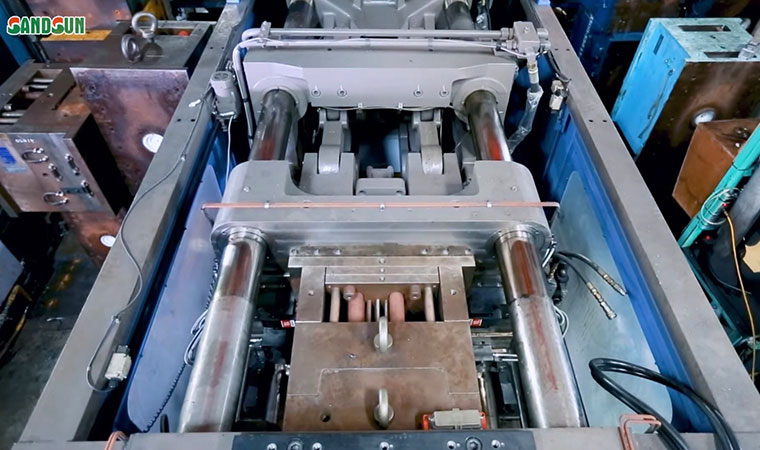

Magnetic Clamping System FQA

In the current environment, it is a good time to introduce magnetic clamping system, only need one operator. This reduces labor costs and labor consumption, and the mold change speed is faster than hydraulic clamping. The latest magnetic structure and outstanding design of magnetic circuit achieves a 20% and more of the magnetic force than traditional magnetic plate design. And SANDSUN magnetic clamping have 8 special safety function designs.

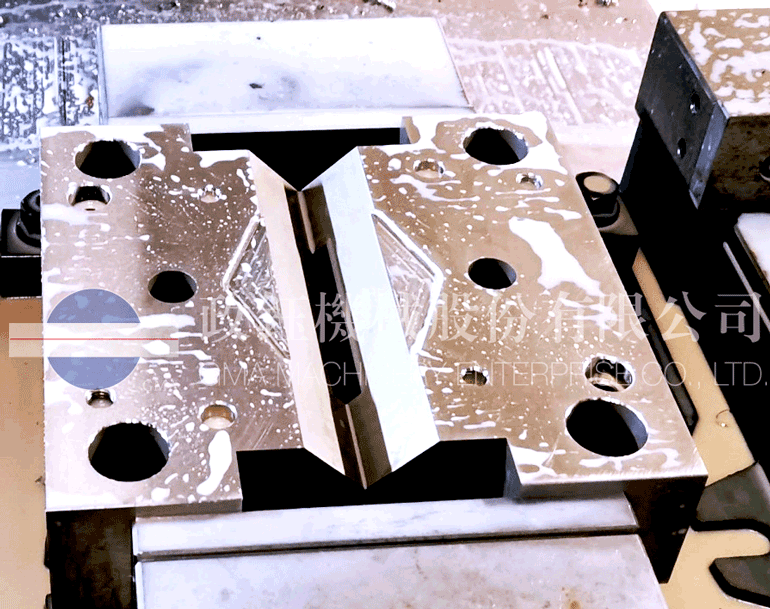

5 Tips for Efficient Injection Molding Mold Change Procedure

Regardless of the metal stamping production line or the injection molding production line, mold changing s often one of the most time-consuming procedure, and a lot of intangible waste is also generated during mold changing. In addition, in traditional mold changing process, which must rely on the master’s experience to set molds and adjust molds. However, this technical work has been gradually lost. The younger generation of employees are less willing to engage in mold changing work because this job is relatively dangerous and tired.

PLASCO MONOFILAMENT LINE & STRAPPING BAND LINE & RAFFIA TAPE & TWINE EXTRUSION LINE

PLASCO is an Industry leader in design, manufacture, and supply of innovative plastic extrusion line to the market worldwide. Our performance spectrum range from individual extruder machine, to the engineering, planning, and delivery of complete turn-key factories. We offer our customer our specialty knowhow in the field of plastic extrusion, our innovations and engineering background is our core competence to provide customized solution and has driven us success for more than 30 years.

New Milestone of GMA—HASTELLOY Processing & Application

HASTELLOY® C276 (UNS N10276, hereinafter referred to as C276) is one of alloy to be well against high corrosive chemical, such as Chloride gas、Hypochlorite、Chlorine dioxide, special to Oxidizing salt solution (such like Ferric Chloride and Copper chloride), C276 is with excellent tolerance, currently, C276 is recognized as the best alloy for anti-corrosion metal.

3 Simple Secrets for Ecofriendly and Cost Saving Blow Molding

One thing that makes blow molding so great are its endless applications. In fact, plastic products are everywhere, making it clear how incredibly useful this material is in modern life. However, in today’s world, the production of these products is not just a matter of their unit price, quality, or visual appearance; customers and end users also care about their sustainability, and they care a lot.

Cutting Machines 101 with Alber Bandknives Germany

Because they are so commonplace, cutting machines are often overlooked. They do not require the chemical expertise of continuous foaming, but they are still a school of knowledge unto themselves. Sunkist has decided to collaborate with Alber Bandknives Germany. We’re bringing you expert knowledge about cutting polyurethane foam from both the machinery end and the blade end.