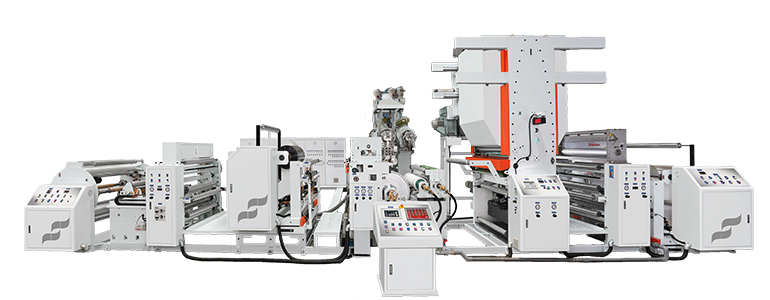

Worldly "High Speed Co-extrusion Coating Laminating Machine" equipped with two exclusive technologies

Since it’s founding, Worldly has provided all types of flexible packaging machines that are able to surpass customer needs. Product examples include: rotogravure printing machines, laminating machines, coating machines, and extrusion coating laminating machines. The machines are used extensively in many different industries,including: biotechnology, chemical, daily necessities, food, agricultural products and more. Worldly has been in the flexible packaging industry for a number of years, and throughout this time have achieved world leading technology and a global customer base. The focus for Worldly now is on innovating our extrusion lamination processes, as that is what the market demands. This is going to be the key to success for Worldly in the future.

The new “High Speed Co-extrusion Coating and Lamination Machine” was launched in the first quarter of 2018. With high-speed production of 250 to 300 meters per minute, the new High Speed Co-extrusion Coating and Lamination Machineisable to meet the high standards that the market demands, for lamination of multi-layered composites. The focus for Worldly is on “high-quality” and “high-capacity competitiveness.” In addition, the "Trimming-less inner deckle system" and "trimming blade online changing device" are the two major focal points of the new machine. Therefore, using trimming-less system to achieve low waste is no longer just a concept, but a reality.

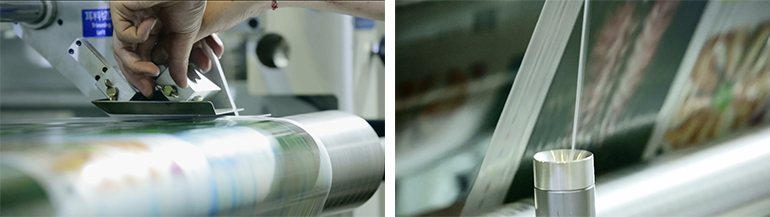

Trimming-less inner deckle system; save material and reduce worry

Because of beading and trimming winding issues, it is difficult for many machines to laminate constantly for a long period of time without a reduction in the quality of edge thickness. This machine increases reeling efficiency and reduces edge beading problems. This establishes production standardization and enables waste savings through better consistency, giving a competitive advantage in today's' market. In order to effectively implement this system, Worldly has started to develop a more user-friendly and simple internal design. Meaning that every company can achieve the goal of "low waste lamination”

This concept has certain benefits including:

1. Save raw materials, greatly reducing the amount and the cost of the raw materials.

2. Stable extrusion performance

3. Sustained and stable production at high speeds. Giving operators more time to perform other tasks, rather than constantly monitoring any edge issues.

4. Ease of operation. Even inexperienced operators can control with ease.

5. The finished product is flat, smooth and hasa consistent highquality edge.

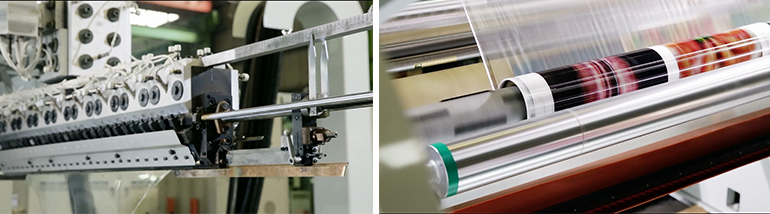

Blade Changing Without Downtime, Safe and Efficient

The blade is used to trim waste scraps from the laminate and because of the high speed production process. It gets worn out quickly so needs to be changed. In traditional machines, this means downtime for the machine which means lost production and profits. Worldly has now designed a structure that can change the blade without stopping the production process. This supports even higher speeds of production.

The advantages of this design are:

1. Change blades quickly and easily

2. No need for hand-held grinding tools(Improved safety)

3. Fine tune blade positioning

4. Smooth edge trimming resulting in less breakage of trimming offcuts

On the day of the interview, Kaushik Nag, CEO of Flexible Packaging Division of Vijayneha, India, and Shahid Akhtar Khan, Supervisor of Quality and Technical Services, came to the test machine. Kaushik Nag, CEO stated: “The Indian market is not unfamiliar with Worldly, their innovative capabilities and brand reputation is particularly attractive to Indian manufacturers who are striving for stable growth. In recent years, India's converting industry has flourished, and the corresponding demand for flexible packaging is increasing. The ‘High SpeedCo-extrusion Coating and Lamination Machine from Worldly meets our needs. ”

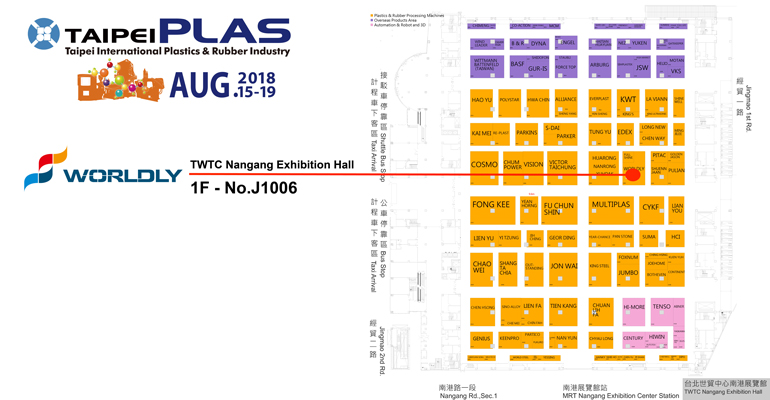

The launch of the "High Speed Co-extrusion Coating and Lamination Machine", got an enthusiastic response from the market. This was a defining mark in verifying the R&D focus of the company that really helped to make the Worldly brand synonymous with product development. One of the original mottos of Worldly is "designing for operators" Our bold new design, successfully created a lamination machine that meets industry leading standards, providing machinery that doesn’t require years of experience to operate effectively and eliminating waste scrap saving costs for the business. These dual benefits show that Worldly is taking note of current issues, by providing safety in the workplace, while at the same time reducing wastage and therefore pollution to the environment. Worldly has more developments like this in the making and we look forward to hearing from you, so you can find out more.

Worldly always uses the customer's need as the starting point, stays true to the original purpose of the company and develops new technologies with customers from all over the world, to create a bright future for the flexible packaging industry. Watch this space for more advances in technology and practices that Worldly will be bringing to the market.

|

Official website Worldly in PRM |