Solvay Doubles PVDF Capacity in China Ahead of Schedule to Meet Growing Demand for EV Batteries

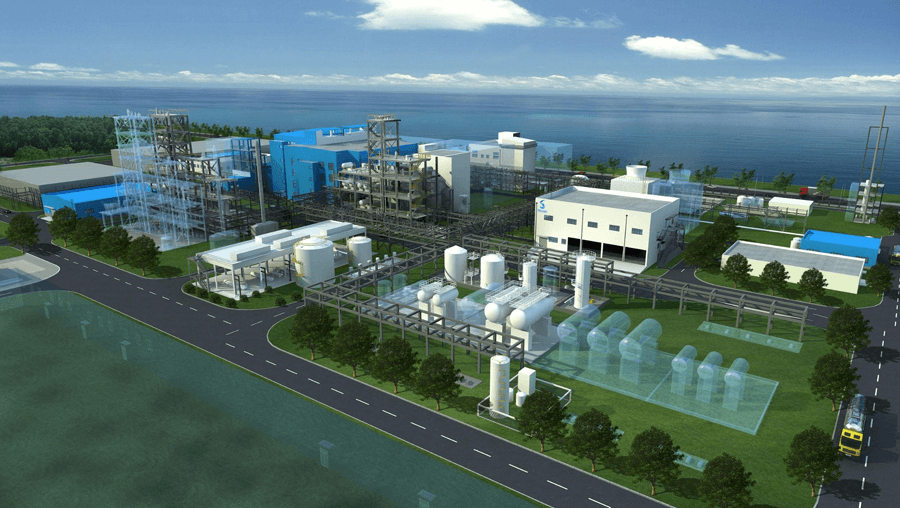

Solvay’s Changshu site has significantly increased production capacity for Solef® PVDF, demonstrating the Group’s commitment to meeting the needs of customers worldwide.

Solvay continues to extend its leadership position in the global lithium-ion battery market with the early completion of its PVDF capacity increase in Changshu, China. The Group has now more than doubled the onsite production volume of its high-performance polymer Solef® polyvinylidene fluoride since mid-May 2022.

The rapid growth of electric and hybrid vehicles is driving record demand for PVDF. This thermoplastic fluoropolymer is used both as a binder and a separator coating in lithium-ion batteries. It plays an essential role in ensuring that batteries perform better, last longer and operate safely. Developed using Solvay’s research and innovation expertise in fluorinated chemistry and polymerization technology, Solef® PVDF is an industry-leading product, inspiring the continuous development of new solutions that will help meet customers’ needs both now and in the future.

Solvay also recently announced significant investment in Solef® PVDF production at its site in Tavaux, France, which will turn it into the largest PVDF production site in Europe. The increased production capacity in China serves as further evidence of the Group’s deep commitment to ensuring that material is readily available to customers worldwide.

“Demand for lithium-ion batteries is undergoing massive growth," said Francescantonio Azzariti, Head of Commercial for Solvay's Battery Platform. “We are inspired both by the environmental benefits as we transition to cleaner mobility and by the commercial opportunities these new technologies offer.”

Solvay's plans exemplify the execution of its Solvay One Planet sustainability ambitions and G.R.O.W. strategy, which focuses investments on high-growth, sustainable solutions that are aligned with important emerging megatrends. Solef® PVDF has also been recognized as a sustainable and profitable solution by the World Alliance for Efficient Solutions, and was an essential component of the Solar Impulse aircraft, the world's first solar-powered aircraft to circumnavigate the world.

Solef® is a trademark of Solvay.

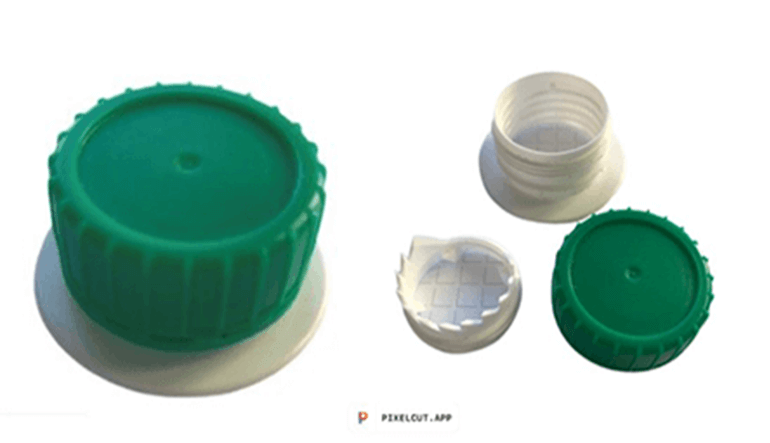

Figure 1: Solef® PVDF increased production at Solvay's Changshu site in China.

Solvay is a science company whose technologies bring benefits to many aspects of daily life. With more than 21,000 employees in 63 countries, Solvay bonds people, ideas and elements to reinvent progress. The Group seeks to create sustainable shared value for all, notably through its Solvay One Planet roadmap crafted around three pillars: protecting the climate, preserving resources and fostering a better life. The Group’s innovative solutions contribute to safer, cleaner, and more sustainable products found in homes, food and consumer goods, planes, cars, batteries, smart devices, health care applications, water and air purification systems. Founded in 1863, Solvay today ranks among the world’s top three companies for the vast majority of its activities and delivered net sales of €10.1 billion in 2021. Solvay is listed on Euronext Brussels and Paris (SOLB). Learn more at www.solvay.com.