BoReTech: PCR Plastic Recycling Process From BoReTech

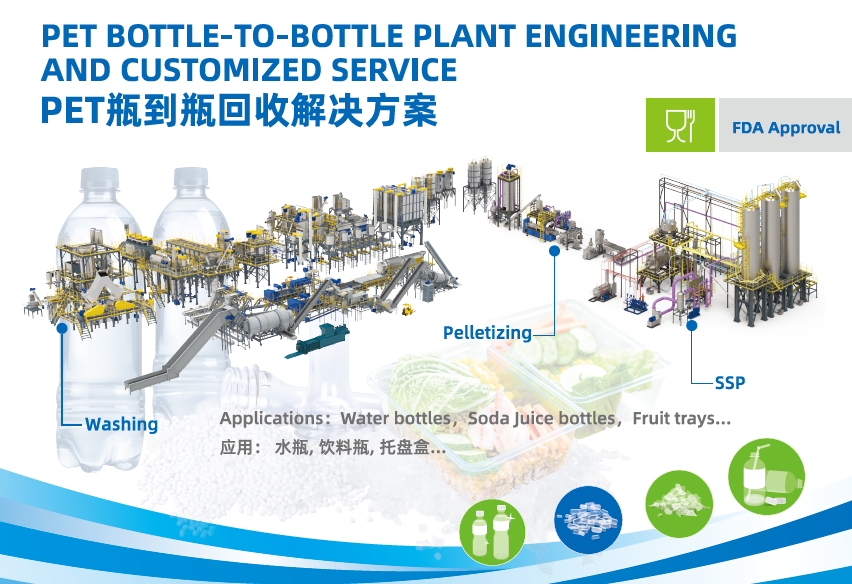

PCR (Post-Consumer Recycled) plastics are made from plastic waste that has been collected from consumer products and recycled. These plastics are mainly derived from PET bottles, HDPE bottles, and LDPE films. For food-grade waste plastic recycling, PET bottle recycling is a major development trend in the waste plastic recycling industry. The process of recycling and washing PCR plastics involves several steps, including washing, grinding, pelletizing, and SSP (Solid State Polymerization) to produce food-grade recycled flakes and pellets that meet FDA or EFSA certification.

To produce PCR plastics, less energy and raw materials are required compared to producing virgin plastics. Although the molecular chains of the plastic are degraded during the recycling process, PCR plastics can still be recycled several times, making them eco-friendly, energy-saving, and recyclable plastic. The use of recycled plastics helps to promote global sustainability goals and also has significant social and economic benefits.

Recycling PET bottles not only reduces landfill waste but also helps reduce plastic pollution in the ocean and air pollution. For every 1 kg of PET virgin granules produced from petroleum, 1.578 kg of CO2 is emitted, whereas the Bottle-to-Bottle process emits only 0.688 kg of CO2 equivalent.

According to a report by Wood Mackenzie, the global consumption of recycled PET is 23.51 million tons, with a global PET recycling rate of about 57%. However, there is still a lot of PET waste that can be saved and recycled. Many brands have begun to use recycled plastics in their products and increase the proportion of recycled plastics to achieve their sustainability goals. The textile and packaging industries are among the sectors that are increasingly using recycled PET, which means more rPET needs to be collected and recycled. This requires the industry to take measures to improve PET recycling technology to meet the increasing demand for high-quality recycled PET.

BoReTech (Zhejiang boretech environmental engineering co., ltd.) is one of the companies that has developed advanced PET bottle recycling and renewing technology. Boretech ES PROCESS PET bottle recycling system uses an automated and water-saving system to achieve stable production, reduce labor, and improve product quality. The output of the recycled PET flakes is of high quality, with low impurities, and stable quality which has received FDA approval.

Big advantage of Boretech ES process PET bottle washing line

- The input through capacity is stable, the degree of automation is high, and the amount of labor is less.

- The line occupies a small area with a high degree of vertical integration and utilization.

- It is safe to operate, durable, and easy to maintain.

- The output RPET flakes have a high quality, less impurity content, and stable quality.

BoReTech encourages customers to make high-grade and good-quality recycled PET flakes, oriented to food-grade PET bottle-to-bottle production and pays great attention to and promotes the opening of recycled materials in the Chinese market for food-grade packaging in the future.

BORETECH PET BOTTLE-TO-BOTTLE RECYCLING PLANT AND PROCESS, and also supply the recycling process for PET tray washing.

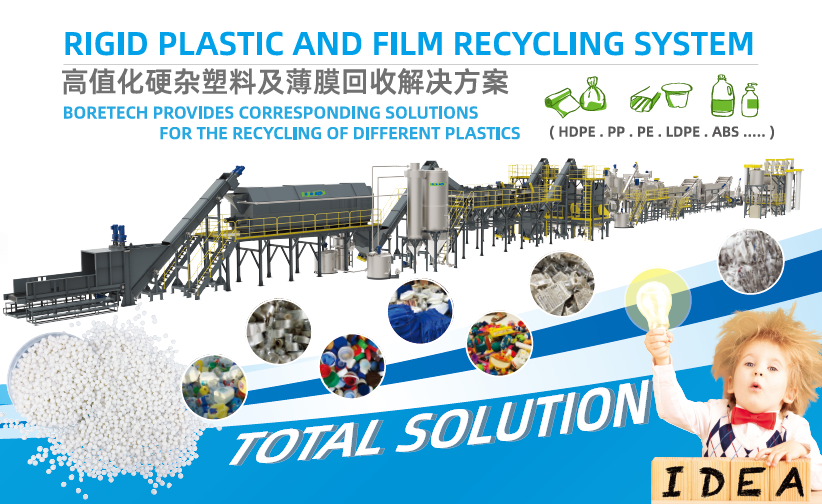

Apart from PET bottle recycling, BoReTech also recycles other types of hard plastic and film plastics such as HDPE, PP, PE, and LDPE.