Advantages of using Extrusion Blow Molding Machines: Your Best Solution for Aquaculture Fish Farming Floats!

Blow Molding machines have many advantages when it comes to making hollow plastic products, and especially for large hollow plastic products they are really your best solution.

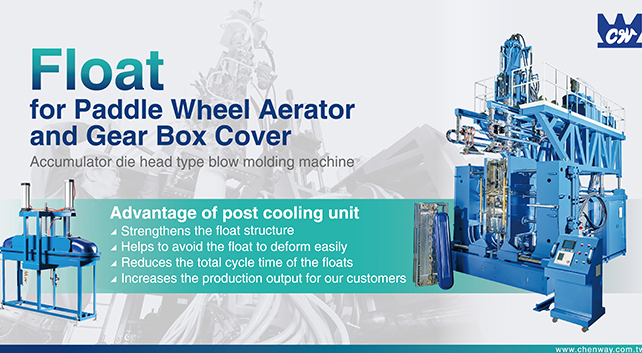

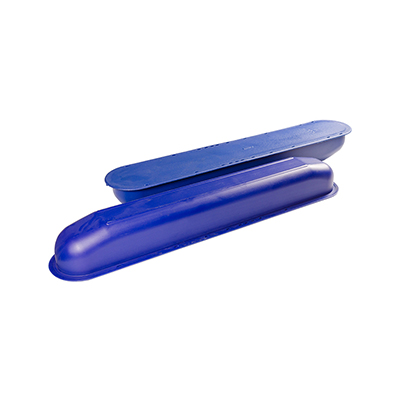

As an example, one very popular and common application of Blow Moulding for large products is the molding of Paddle Wheel Aerator Floats and Gear Box Covers for Aquaculture; these floats are used in Fish Farming to hold the Paddle Aerators Wheels that give the fish the oxygen they need from the environment for respiration.

The Key features of our Customized Accumulator Head Blow Molding Machine for Aquaculture Fish Farming Floats are:

- Accumulator Die Head:

Our Blow Molding Machine is equipped with an Accumulator Head designed with two heart-shaped flow channels weld line-free to increase the strength of the hollow plastic products.

- Special Clamping Unit:

This Extrusion Blow Molding Machine clamping unit has an equally distributed clamping force along the vertically long plates, which allows the Paddle Aerator Float and Gear Box cover to be perfectly shaped without having any air leakage during formation.

- Injection Speed:

Our Accumulator Head Blow Molding machine combines the adequate injection speed with a Parison control unit, programmed by our engineers to achieve an even thickness distribution along these large hollow plastic products, and especially the Float for Paddle Wheel Aerator, resulting in them being stable and performing as required when put into water.

Finally, the blow molding machine set includes a Customized Post Cooling unit that helps to complete the formation of the Paddle Wheel Aerator Floats.

Advantages of Post Cooling unit for Paddle Wheel Aerator Floats:

- -Reduces the total cycle time of the floats.

- -Increases the production output for our customers.

- -Strengthens the float structure.

- -Helps to avoid the float to deform easily.

As a result, your Floats for Paddle Wheel Aerator performance will be unbeatable if made with our Blow Molding machine!

Watch below videos of our Accumulator Head Blow Molding machine running in one of our customer’s factory:

|

| Official Website https://www.chenway.com.tw/en/index.html Chen Way on PRM-TAIWAN https://www.prm-taiwan.com/com/chen-way.html |